Easily-soluble magnesium alloy material as well as production method and application thereof

A magnesium alloy, easily soluble technology, applied in the field of magnesium alloys, can solve the problems such as being unsuitable for the progress and development of modern oil extraction technology, high density, harmful and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1, the easily soluble metal magnesium alloy material in the present embodiment comprises following composition by weight percentage:

[0087] Al: 10.0%; Li: 0.3%; Ca: 0.3%; Zn: 0.2%; In: 0.03%; Ga: 0.0%; Si: 0.1%;

[0088] Mn: 0.8%; Zr: 0.0%; Fe: 0.016%; Ni: 0.5%; Cu: 0.15%; the balance is Mg and unavoidable impurities.

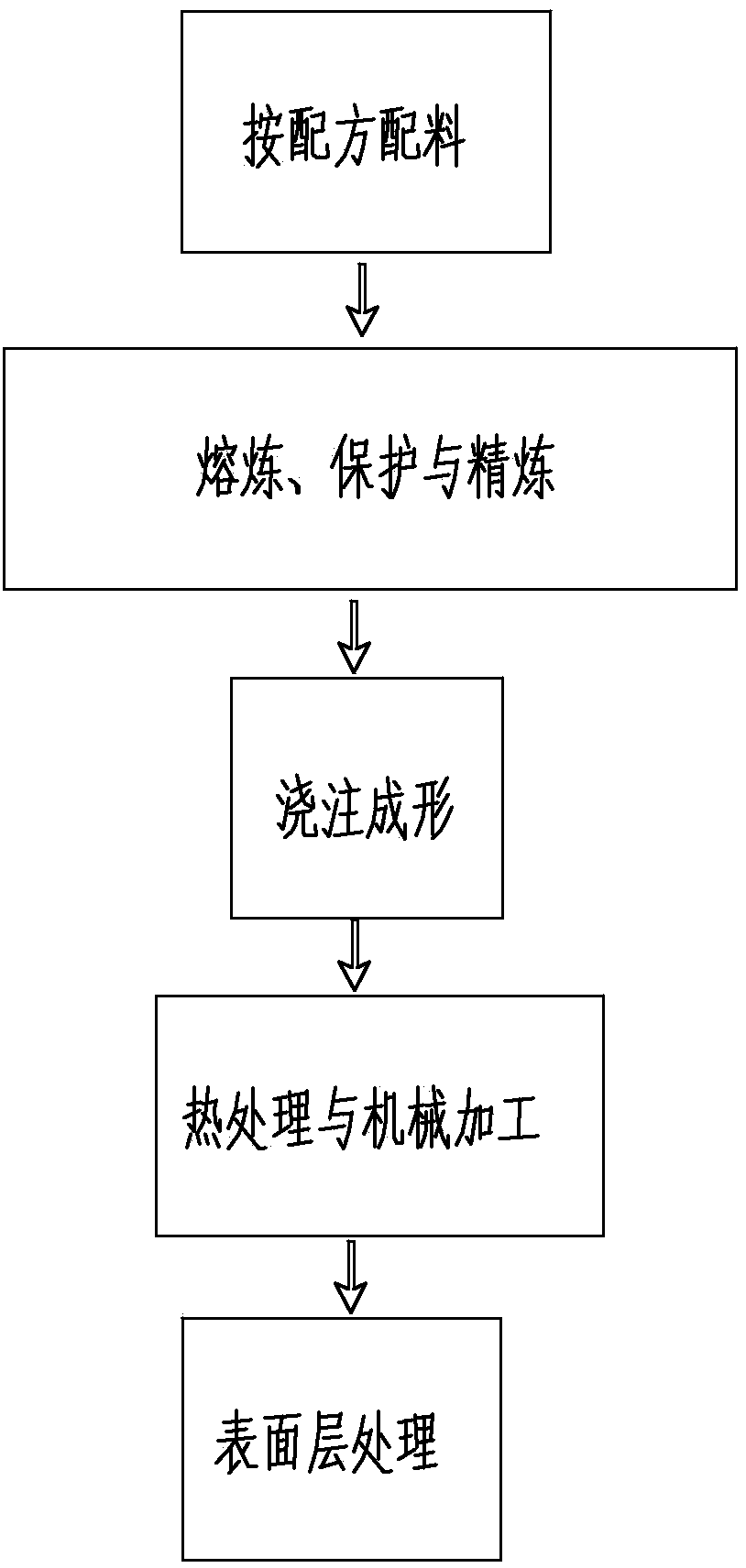

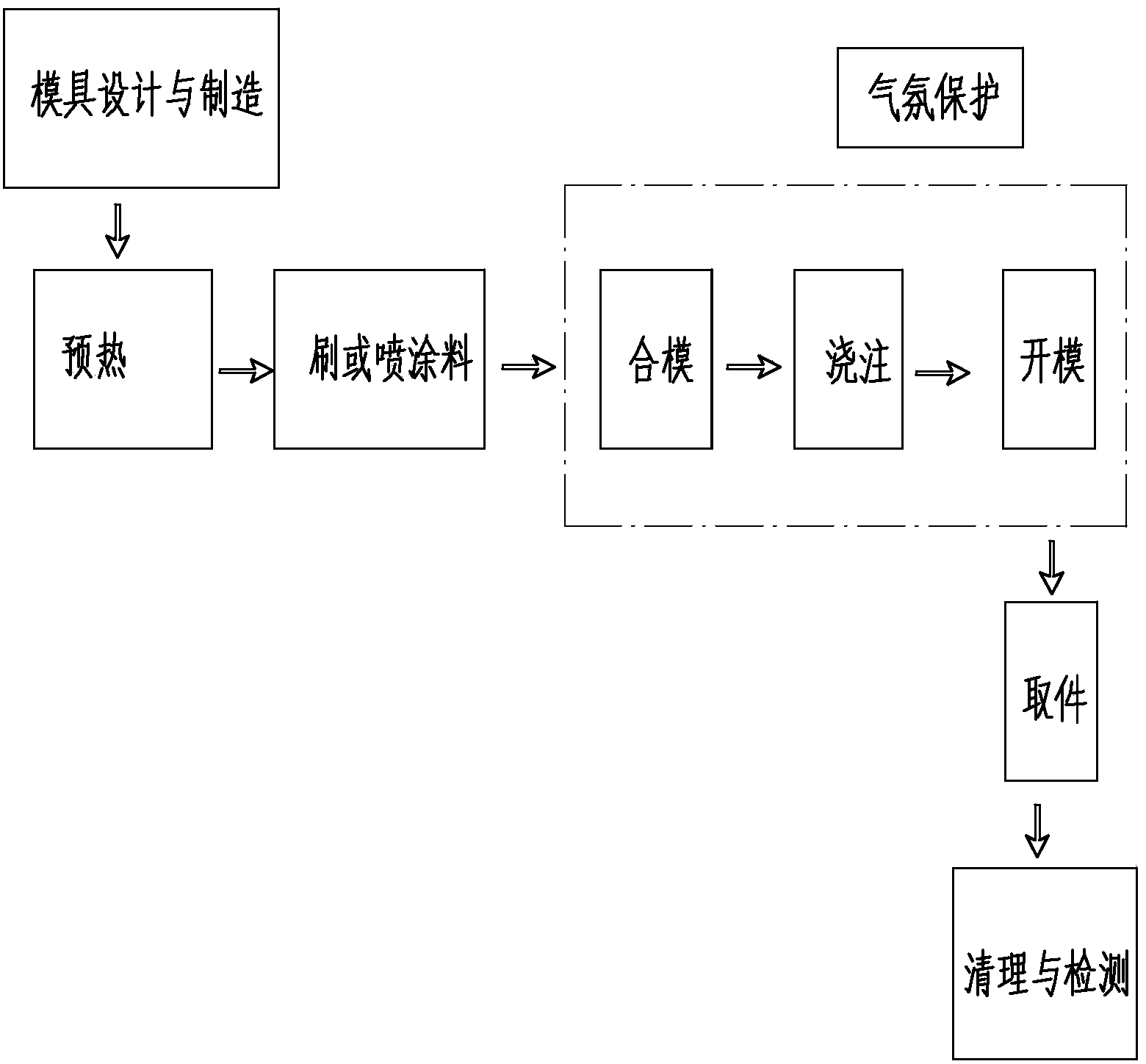

[0089] combine figure 1 As shown, the manufacturing method of the soluble magnesium alloy material in this embodiment specifically includes the following steps:

[0090] ① Ingredients according to the formula:

[0091] According to the alloy formula of the present invention, the batching is accurately weighed. It uses aluminum-silicon, aluminum-iron, aluminum-nickel, aluminum-copper, aluminum-manganese master alloys and pure aluminum, pure magnesium, pure zinc, pure calcium, pure lithium, and pure indium in the form of furnace materials, which are classified for precise batching.

[0092] ②Smelting, protection and refining:

[0093] Aft...

Embodiment 2~ Embodiment 14

[0106] The easily soluble metal magnesium alloy material in each embodiment comprises following composition by weight percent:

[0107] Table 1 embodiment 2~embodiment 14 weight percentage example composition

[0108]

[0109]

[0110] All the other preparation steps and technical effects are the same as in Example 1.

[0111] The products prepared in the above examples can also meet the requirements for use. Using soluble magnesium alloy materials to replace steel and aluminum products can avoid the high energy consumption and high cost of drilling and grinding secondary processing; replacing low-melting point high-density soluble or soluble alloy products can avoid unsuitable flowback, Technical problems of environmental pollution; replacing organic materials can avoid problems of deformation, easy jamming, and refractory degradation. It is estimated that only soluble balls in each well will bring direct benefits of 30,000 yuan, reduce mining costs by 50,000 yuan, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com