A Continuous Mining Method for Side Coal in Large Dip Thick Coal Seam

A mining method and technology for thick coal seams, which are used in open-pit mining, earthwork drilling, special mining, etc., can solve the problems of large mining-stripping ratio, labor intensity of workers, and difficulty in discharging exfoliated materials, so as to reduce mining and stripping. ratio, improving economic efficiency and safety, and improving the effect of coal resource recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

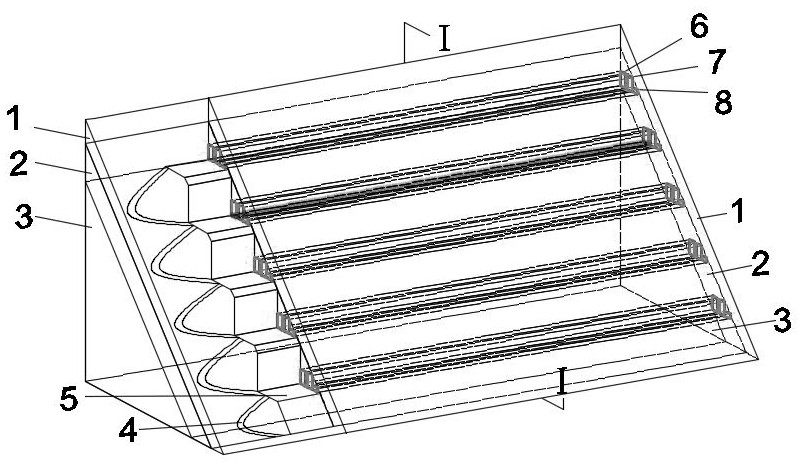

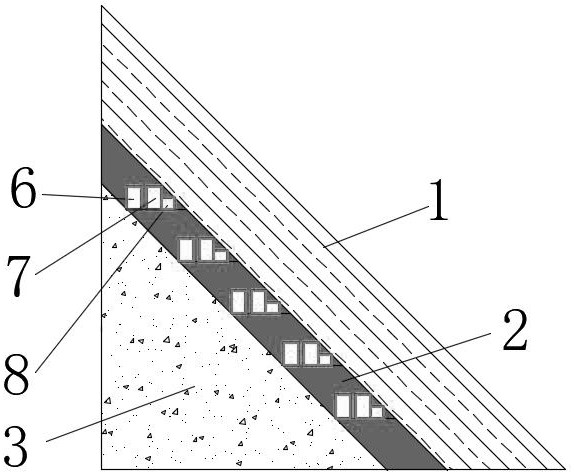

[0024] Continuous mining method of the open coal coal in the open coal mine, including the following steps,

[0025] S100 ~ Divided the inclined coal seam of the coal seam, in the direction of the coal seam, the vertical height of each 5 to 15m is sequentially opened in the vertical height of the lower step 5;

[0026] S200 ~ upper, lower adjacent panel industrial squares set annular transport channel 4: 4: 4 of the panel industrial squares disclosed coal seam 2 and flat;

[0027] S300 ~ During the exploitation, the panel industrial square 5 area is installed, and the panel industrial square of each step is set to set up.

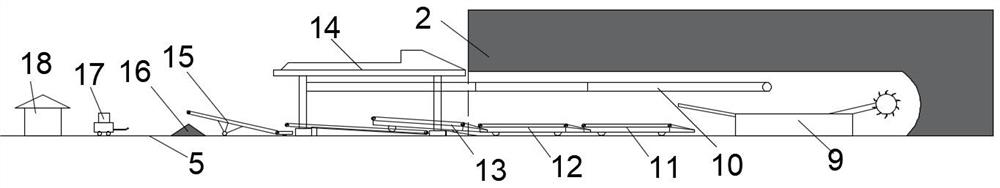

[0028] The outer portion of the mining 6 mining position in the top panel industrial square 5, the continuous coal mining machine 9, the air cylinder 10, the speed-clad tape transport unit I11, the stepping platform 14, the mobile discharge portion 15, and the mobile control Platform 18; Speed Tape Transportation Unit I11 Connect the tail of the transport por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com