Bag type filling machine for open-air end slope coal-pressing filling mining

A filling machine and filling bag technology, which is applied in the direction of filling materials, ground mining, mining equipment, etc., can solve the problems of threatening the life safety of production equipment workers, low recovery rate of end-side pressure coal resources, insufficient support strength of filling bodies, etc. , to achieve the effects of increasing economy and applicability, improving filling rate and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

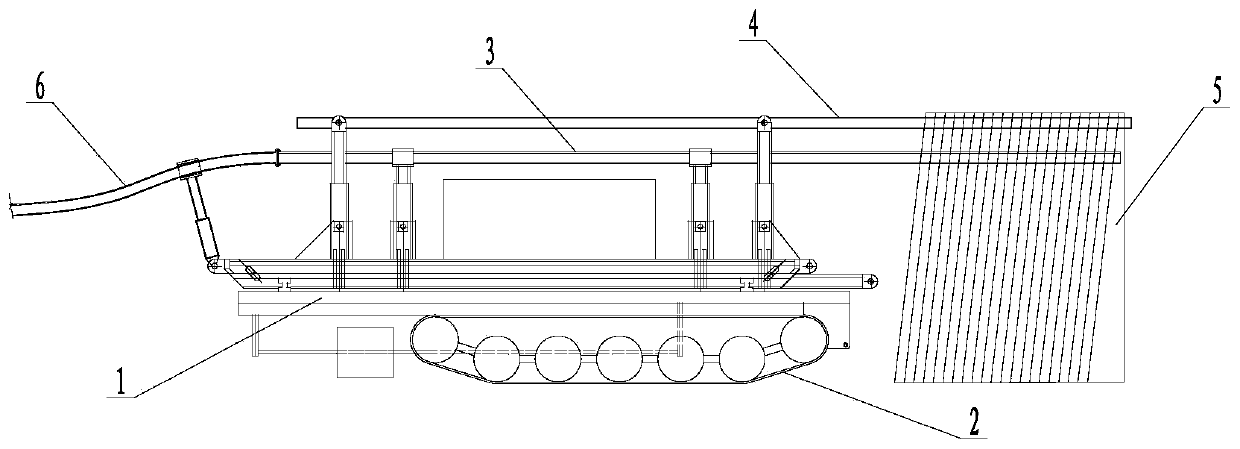

[0032] Such as Figure 1 to Figure 5 As shown, the present invention provides a bag-type filling machine for open-pit end-side pressure coal filling mining.

[0033] Among them, the fuselage 1 is installed on the running device 2; the filling pipe 3 and the suspension device 4 are installed on the fuselage; the filling bag 5 is suspended on the front end of the suspension device 4; in the working state, by running the bag filling machine to the filling roadway and then use the filling pipe 3 to inject the filling into the filling bag 5. During the process of the bag filling machine retreating from the end of the filling roadway, the entire filling roadway will be filled by injecting the filling material 5 into the filling bag. Filled to ensure the stability of the open end gang.

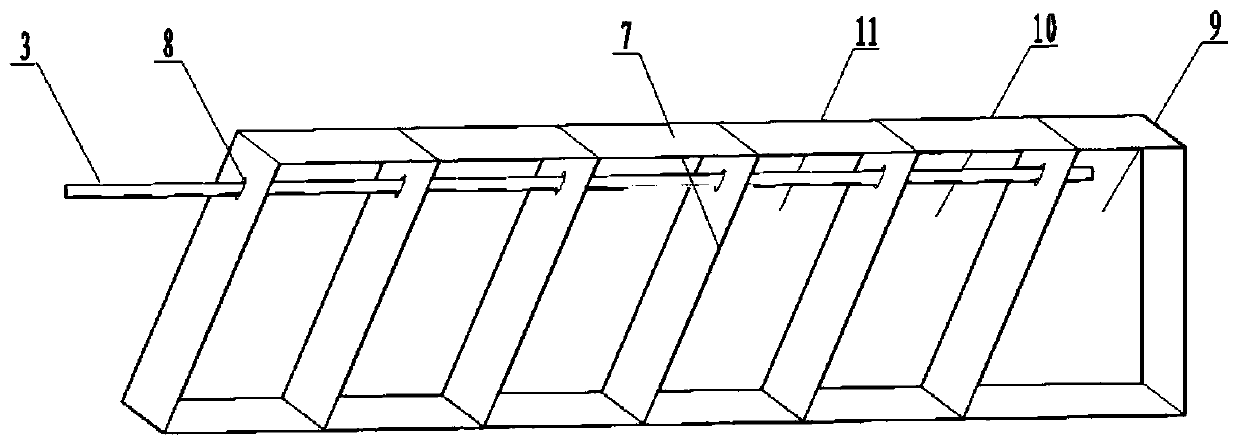

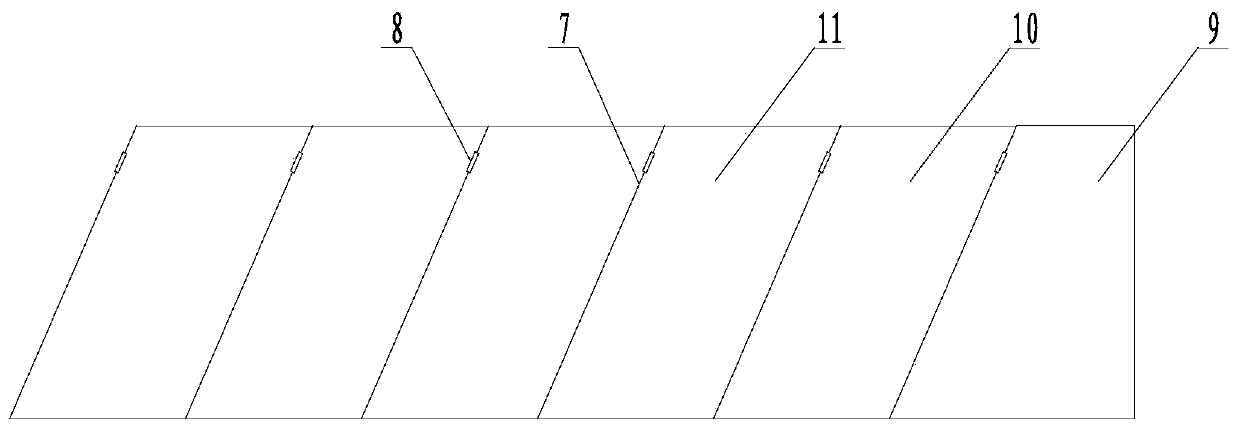

[0034] The filling bag 5 is provided with a set of partitions 7, and the filling bag 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com