A continuous coal mining machine for end-side mining in an open-pit mine

A technology for coal shearers and open-pit mines, applied in cutting machinery, slitting machinery, earthwork drilling and mining, etc., to achieve the effects of ensuring accuracy, avoiding excessive slipping, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

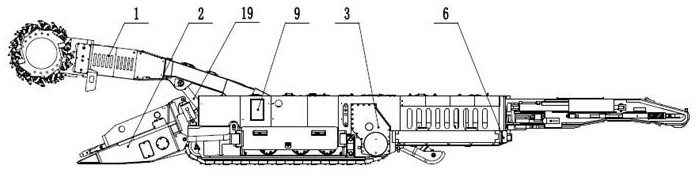

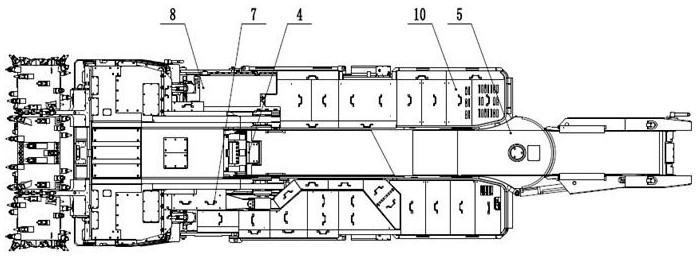

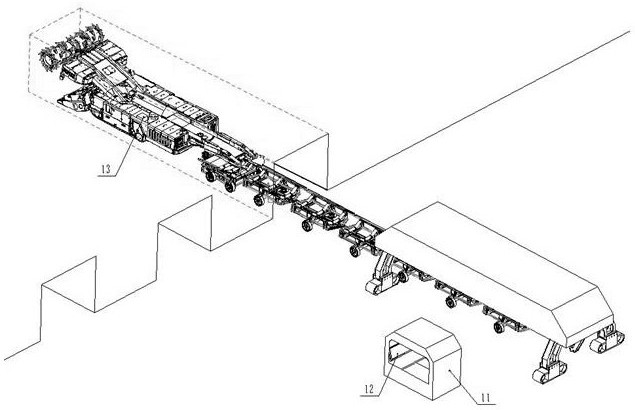

[0029] like Figure 1-2 As shown, the main components of a continuous coal miner for open-pit mine end side mining of the present invention are a cutting part 1, a loading part 2, a left and right walking part 3, a main frame 4, a conveying part 5, a rear frame 6, and a dust removal system 7 , an electrical system 8, a hydraulic system 9 and a cooling system 10. The cooling system 10 adopts a self-circulating cooling system, and the cooling device is arranged at the right rear of the fuselage, which can meet the cooling requirements of open-pit mining without external water supply. The dust removal system 7 consists of Composed of a dust removal fan and an air duct, the dust removal air duct is integrated into the cutting part 1 and the inside of the fuselage. The present invention has a wireless remote precise control system. Operation, the equipment is controlled by an adaptive cutting control system during the cutting cycle operation, and the joint action can realize the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com