Open coal mine end slope mining, discharging and filling mining method

A technology of open-pit coal mines and mining methods, which is applied in the direction of filling, ground mining, mining equipment, etc. It can solve the problems of low recovery rate of end-side resources, pollute surface water and land, and affect slope stability, so as to reduce stripping ratio, pollution reduction, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

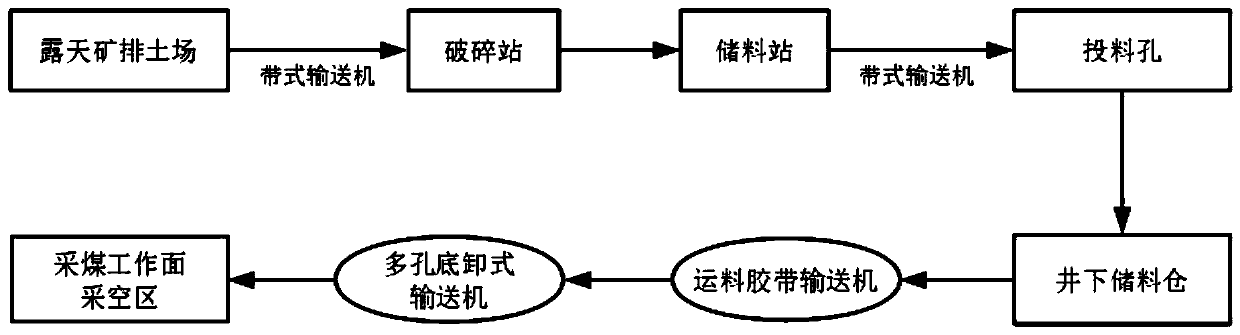

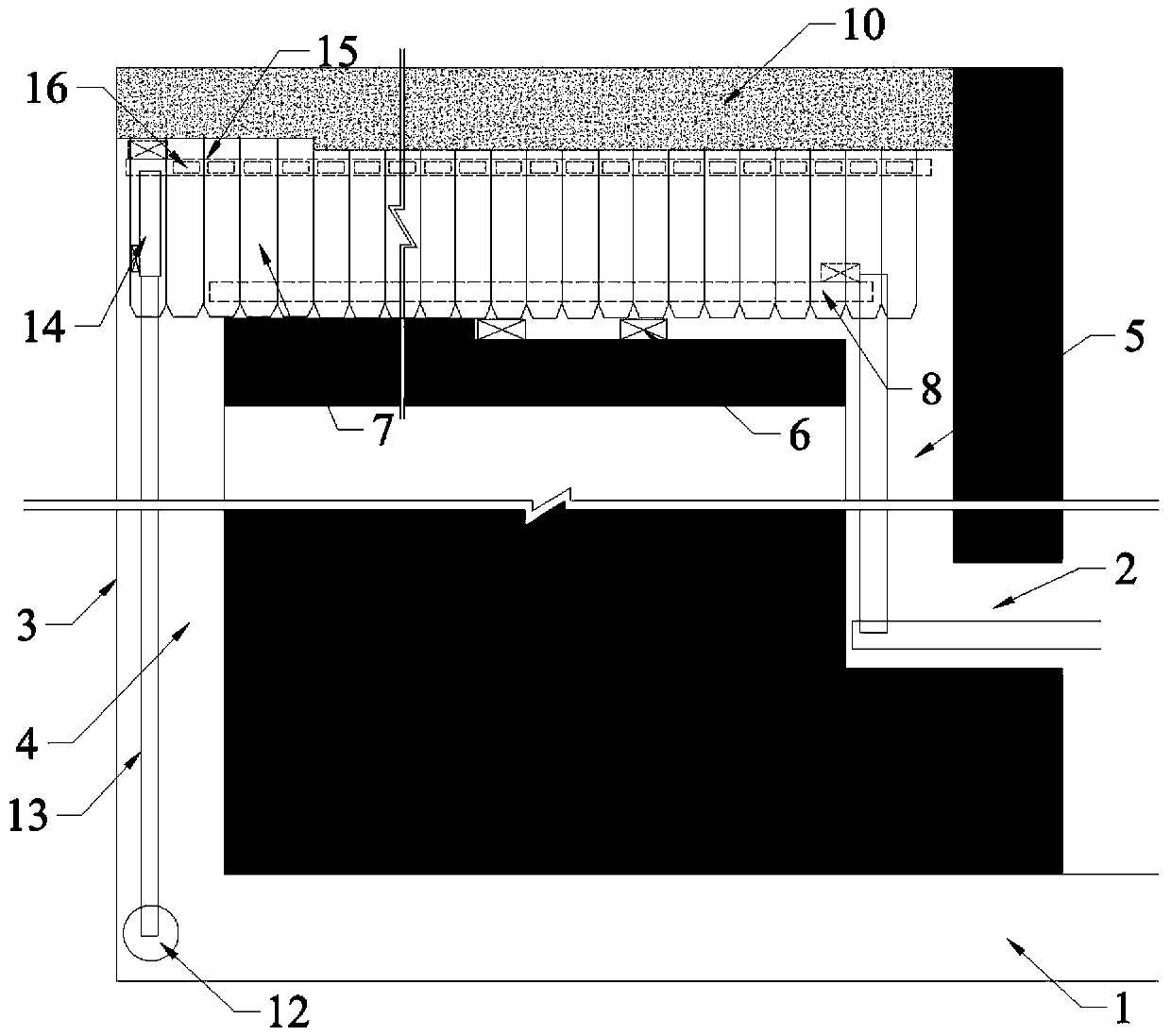

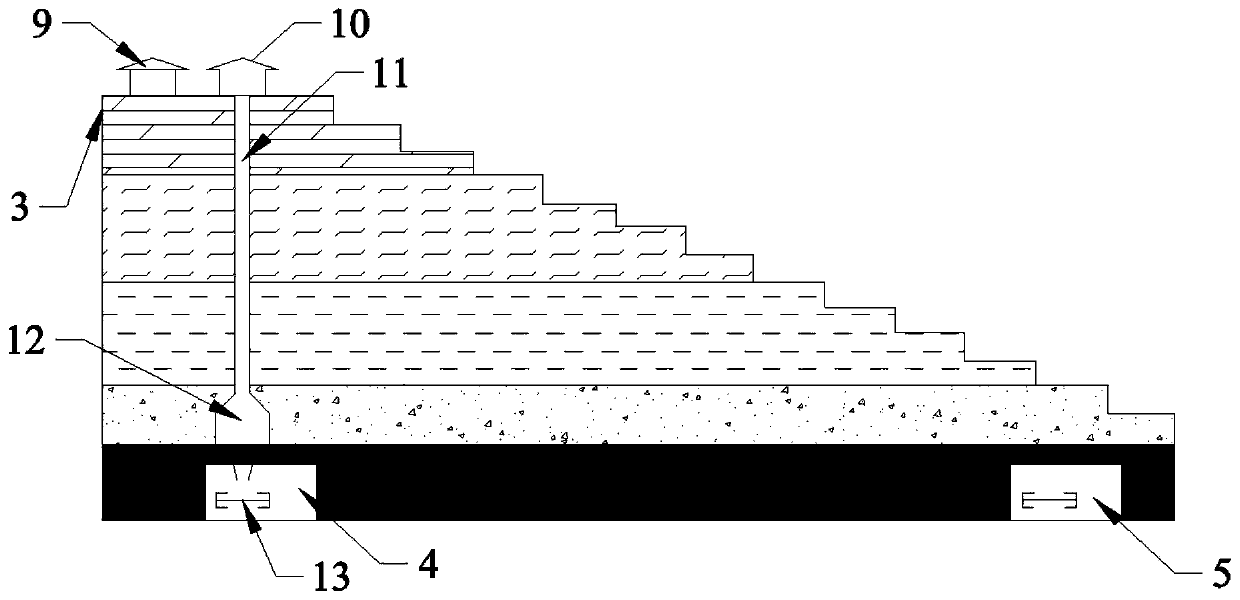

[0025] Such as figure 1 As shown, this method forms a complete set of open-pit slag filling and transportation system, uses the slag piled up in the open-pit mine dump as filling material, and fills the end side to fill the goaf 2 of the coal mining face, while controlling the side slope Safe recovery of side pressure coal. The specific steps are:

[0026] a. At the bottom of the side pit in the open-pit mine, excavate the main entryway 1 and the auxiliary entryway 2 in parallel along the inclined direction of the coal seam; the distance between the main entryway and the auxiliary entryway 2 is 20m, and the main entryway 1 is excavated to 20m away from the mining rights , the auxiliary level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com