A fracturing stimulation method

A technology for fracturing pipe strings and old fractures, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc. It can solve the problems of complex oil-water relationship, water breakthrough or water production in infill wells, etc., and improve reservoir recovery. rate, increase the volume of reformation, and increase the effect of recoverable reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A fracturing stimulation method, comprising the steps of:

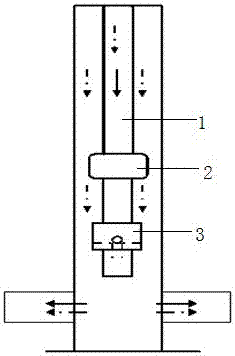

[0023] Step 1: Run the fracturing string 1 into the formation where the old fracture is located, and perform hydraulic fracturing on the perforated section of the formation to open the old fracture;

[0024] Step 2: Use proppant, sand plug, and temporary plugging agent to shield and temporarily plug old fractures to form main fractures and branch fractures; add proppant, sand plug, and temporary plugging agent to the old fractures according to the mass fraction ratio of 5: The mixture composed of 2:1 can shield and temporarily plug the old cracks, and press the old cracks to form main cracks and branch cracks;

[0025] Step 3, throwing a ball to knock down the sliding sleeve restrictor 3 on the fracturing string 1;

[0026] Step 4, use slick water to carry proppant to support the branch fractures, base fluid and cross-linking fluid respectively carry proppant to support the main fractures; add the mixture of p...

Embodiment 2

[0034] On the basis of Example 1, specifically, the particle size of the proppant in step 2 is 8 mesh to 16 mesh, the temporary plugging agent is CDD-3 oil-soluble fracture temporary plugging agent, the particle size is 3mm~6mm, and the CDD -3 The density of the oil-soluble fracture temporary plugging agent is 1.30±0.20g / cm 3 , Softening temperature: ≥30°C, dissolution time (40°C): <90min.

[0035]Before implementing this fracturing stimulation method, it is necessary to pull out the production string of the original well and clean it, and then use the drilling gauge to drill the well, that is, use the drilling gauge to drill the well to the artificial well bottom of the operating well to ensure that the The wellbore of the operating well is clean. In this way, check whether the inner diameter of the operating well meets the standard through the well gauge. If the operating well is deformed or blocked, check the maximum geometric dimension that the deformed or blocked operatin...

Embodiment 3

[0042] On the basis of Example 2, it should be noted that the particle size of the proppant carried by the slick water in step 4 is 40 mesh to 70 mesh, and the particle size of the proppant carried by the base fluid and crosslinking liquid is 20 mesh to 40 mesh. head.

[0043] Before implementing this fracturing stimulation method, it is necessary to pull out the production string of the original well and clean it, and then use the drilling gauge to drill the well, that is, use the drilling gauge to drill the well to the artificial well bottom of the operating well to ensure that the The wellbore of the operating well is clean. In this way, check whether the inner diameter of the operating well meets the standard through the well gauge. If the operating well is deformed or blocked, check the maximum geometric dimension that the deformed or blocked operating well can pass through. If the size does not meet the fracturing requirements, the well should be repaired first and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com