A kind of method of producing crude oil in sagd wedge area

A crude oil, wedge-shaped technology, applied in the production of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of high cost and high risk, and achieve the effects of accelerated recovery, high safety, and accelerated fusion between steam chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

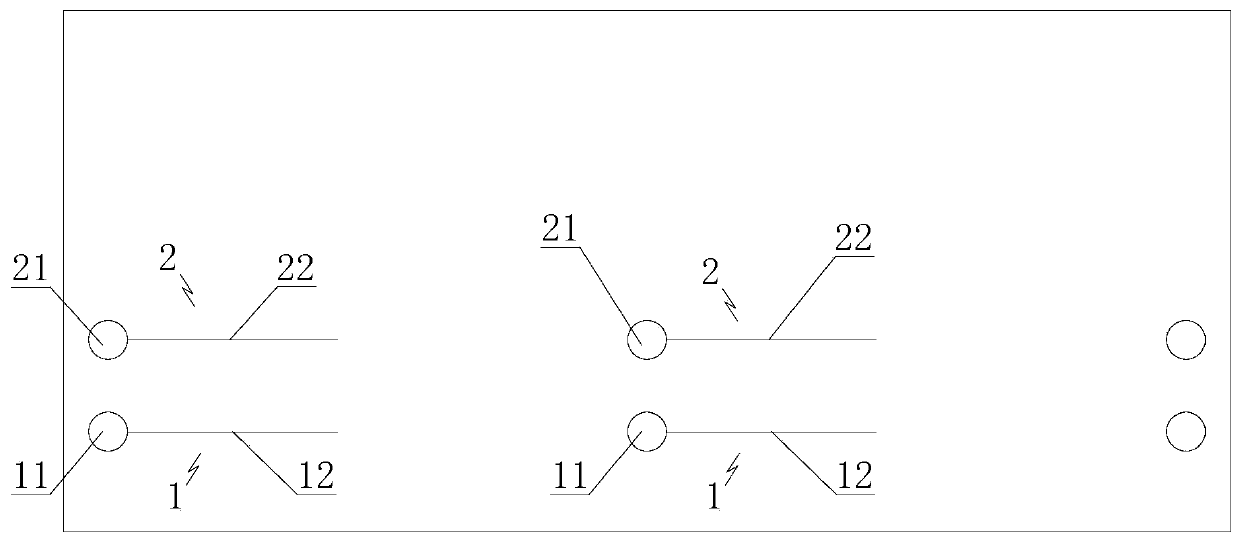

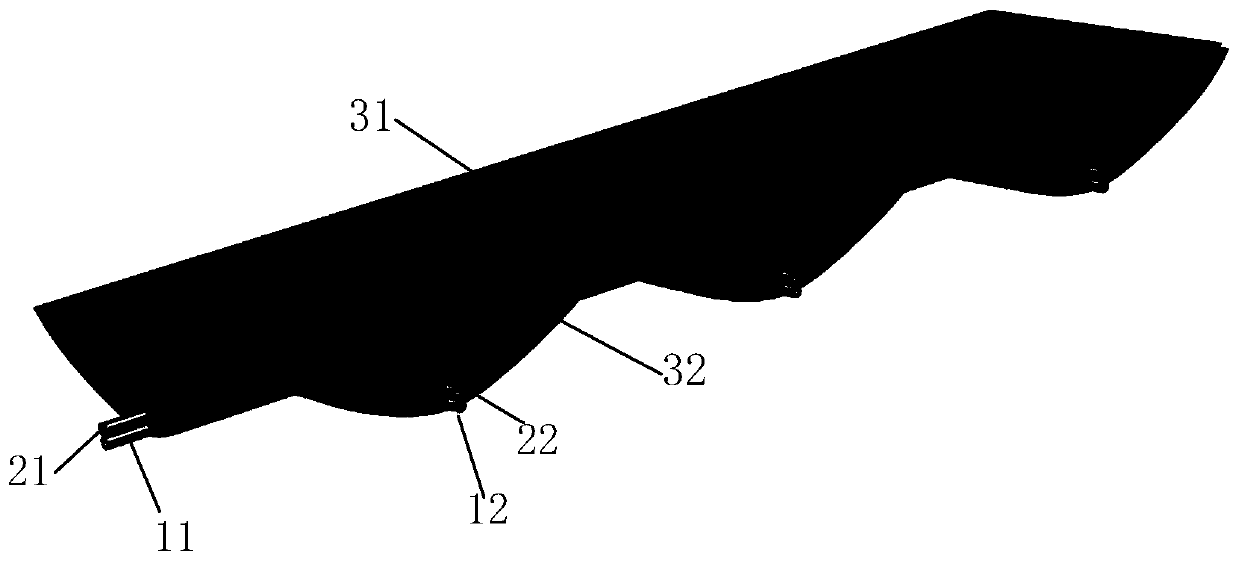

[0061] The buried depth of the target reservoir is 400m, the average effective thickness of the oil layer is 25m, the horizontal permeability is 2Darcy, and the viscosity of crude oil at formation temperature is 100000mPaS. The double horizontal well group is deployed according to the E-type well layout, and the SAGD main horizontal well group spacing (the distance between two adjacent E-type horizontal production well groups 1) is 100m.

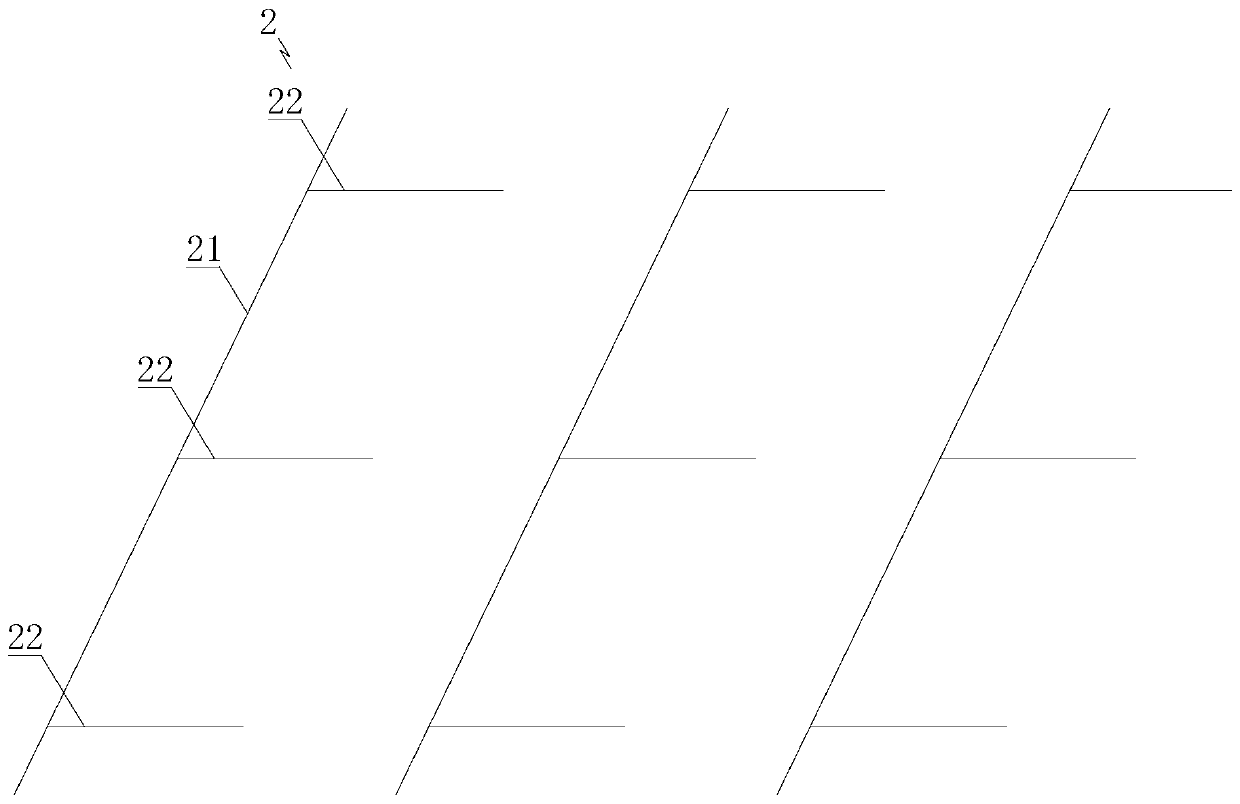

[0062] The horizontal production well 11 is drilled first, the E-type horizontal production well group 1 is deployed 1m (first distance) from the bottom of the oil layer, and the E-type horizontal steam injection well group 2 is 5m above the E-type horizontal production well group 1 (the second distance) , the horizontal section of the horizontal production well 11 is 400m long. Three horizontal production well branch wells 12 are drilled from the tail end of the horizontal production well 11. The borehole diameter of the production well bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com