A Foam Composite Cold Recovery Method for Enhanced Recovery of Heavy Oil Reservoir

A technology for heavy oil reservoirs and recovery factors, which is applied in drilling compositions, chemical instruments and methods, and production fluids, etc., and can solve problems such as limitations in large-scale popularization and application, adaptability and cost, and short effective time. , to achieve the effect of improving heavy oil recovery, increasing stability, and improving foam quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

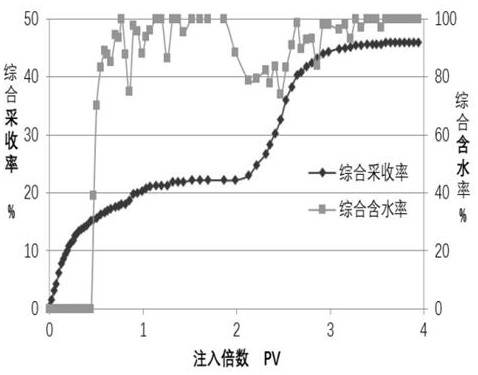

Image

Examples

Embodiment 1

[0027] Example 1: A foam composite cold recovery method for enhancing the recovery of heavy oil reservoirs

[0028] Proceed as follows:

[0029] (1) Water flooding until the comprehensive water content is greater than 95%;

[0030] (2) Inject the heavy oil viscosity-reducing oil-displacement agent into the water injection well, and the volume of the heavy-oil viscosity-reducing oil-displacement agent is 0.04 times the pore volume of the reservoir;

[0031] (3) Inject water into the water injection well to restore water flooding, and the water injection volume is 0.04 times the pore volume of the reservoir;

[0032] (4) The polymer composite foam flooding system is injected into the water injection well, and the volume of the polymer composite foam flooding system is 0.04 times the pore volume of the reservoir;

[0033] (5) Repeat steps (2)-(4) until the total injection volume of heavy oil viscosity-reducing oil displacement agent and polymer composite foam flooding system is...

Embodiment 2

[0036] Example 2: A foam composite cold recovery method for enhancing the recovery of heavy oil reservoirs

[0037] Proceed as follows:

[0038] (1) Water flooding until the comprehensive water content is greater than 95%;

[0039] (2) Inject heavy oil viscosity-reducing oil displacement agent into the water injection well, and the volume of heavy oil viscosity-reducing oil displacement agent is 0.05 times of the pore volume of the reservoir;

[0040] (3) Inject water into the water injection well to restore water flooding, and the water injection volume is 0.03 times the pore volume of the reservoir;

[0041] (4) The polymer composite foam flooding system is injected into the water injection well, and the volume of the polymer composite foam flooding system is 0.05 times the pore volume of the reservoir;

[0042] (5) Repeat steps (2)-(4) until the total injection volume of heavy oil viscosity-reducing oil displacement agent and polymer composite foam flooding system is 0.5 ...

Embodiment 3

[0045] Example 3: A foam composite cold recovery method for enhancing the recovery of heavy oil reservoirs

[0046] Proceed as follows:

[0047] (1) Water flooding until the comprehensive water content is greater than 95%;

[0048] (2) Heavy oil viscosity-reducing oil displacement agent is injected into the water injection well, and the volume of the heavy oil viscosity-reducing oil displacement agent is 0.03 times the pore volume of the reservoir;

[0049] (3) Inject water into the water injection well to restore water flooding, and the water injection volume is 0.05 times the pore volume of the reservoir;

[0050] (4) The polymer composite foam flooding system is injected into the water injection well, and the volume of the polymer composite foam flooding system is 0.03 times the pore volume of the reservoir;

[0051] (5) Repeat steps (2)-(4) until the total injected volume of heavy oil viscosity-reducing oil displacement agent and polymer composite foam flooding system is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com