Method and system for exploiting lamellar super-heavy oil deposit

A production method and technology for ultra-heavy oil, which are applied in the field of production methods and systems of layered ultra-heavy oil reservoirs, can solve the problems of rapid decline in huff and puff production, difficulty in flowing ultra-heavy oil in far-well areas, insufficient displacement production, and the like, Achieve the effect of supplementing formation energy, increasing oil layer temperature, and solving high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

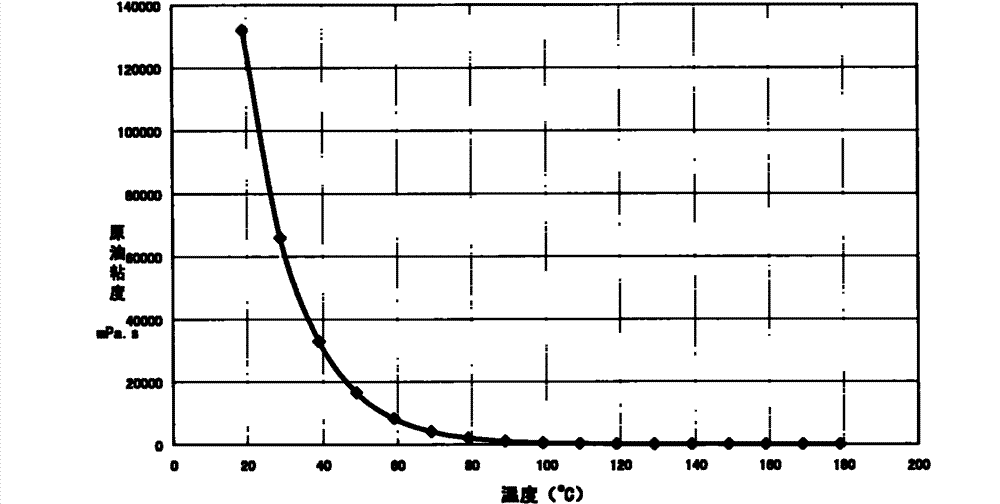

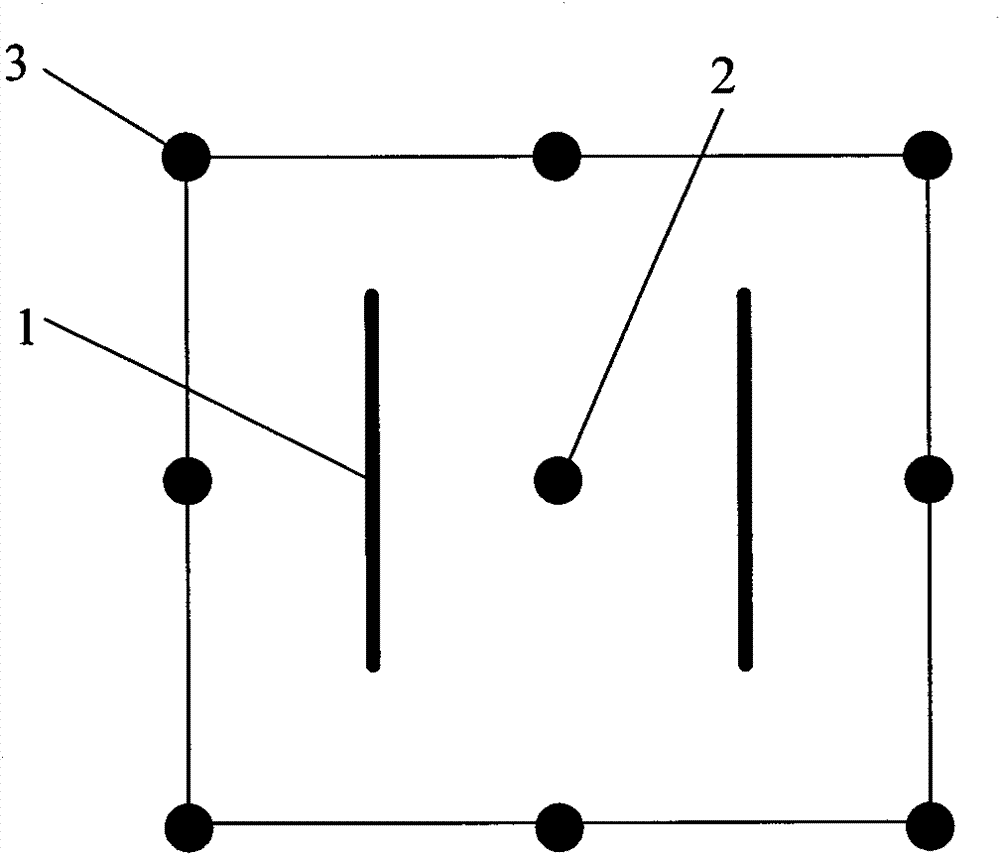

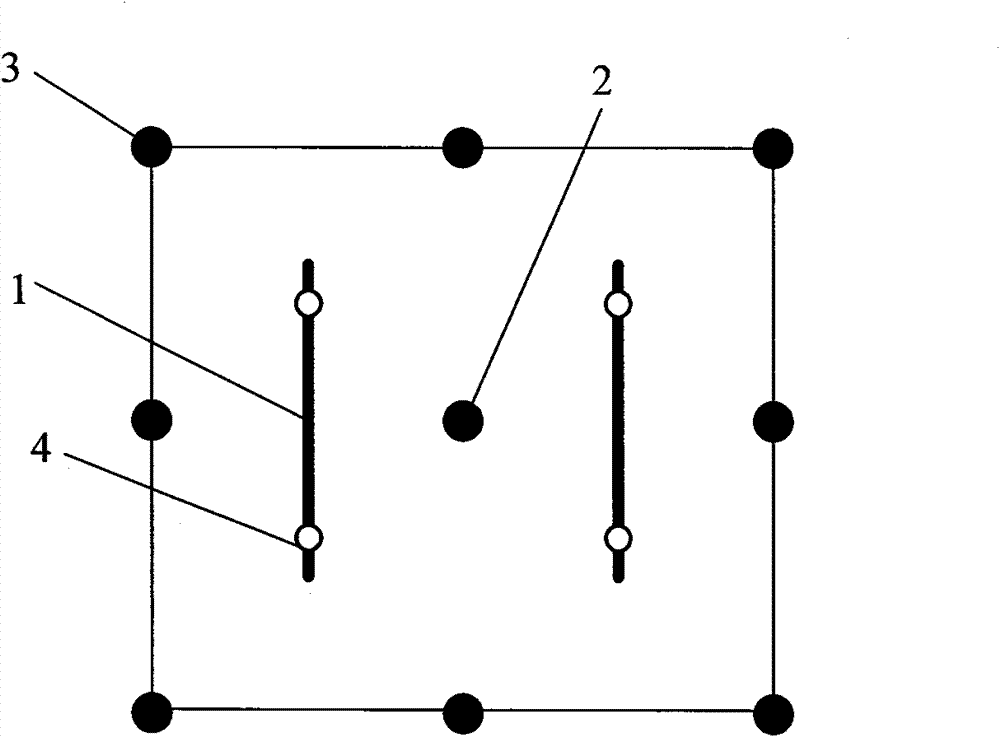

[0037] like figure 1 , figure 2 As shown, the production system is set up according to the fluidity characteristics of super heavy oil represented by the viscosity-temperature relationship curve, and the six oil fields in Karamay Oilfield, Xinjiang 2+3 For example, the viscosity of degassed crude oil at the reservoir temperature is 5-20×10 4 mPa.s, in this embodiment, the viscosity of crude oil is selected at 13.0×10 4 The area of mPa.s was studied by indoor numerical simulation. The production system of this embodiment preferably has two multi-bottom wells 1, one central steam injection well 2 and eight production wells 3 to form a reverse nine-point square well pattern.

[0038] Firstly, steam huff and puff are performed on two multi-bottom wells 1. After 5 rounds of huff and puff, the central steam injection well 2 and the two multi-bottom wells 1 start steam injection at the same time. The steam injection volume is preferably 150-200m 3 / m.ha, the steam injection ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com