Engineering driller for automatically loading and unloading drill stem

An engineering drilling rig, automatic loading and unloading technology, applied in the direction of drill pipe, drilling automatic control system, drill pipe, etc., can solve the problems of unsuitable construction environment, occupying construction channel space, etc., and achieves small space occupation, high connection strength, and reliability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

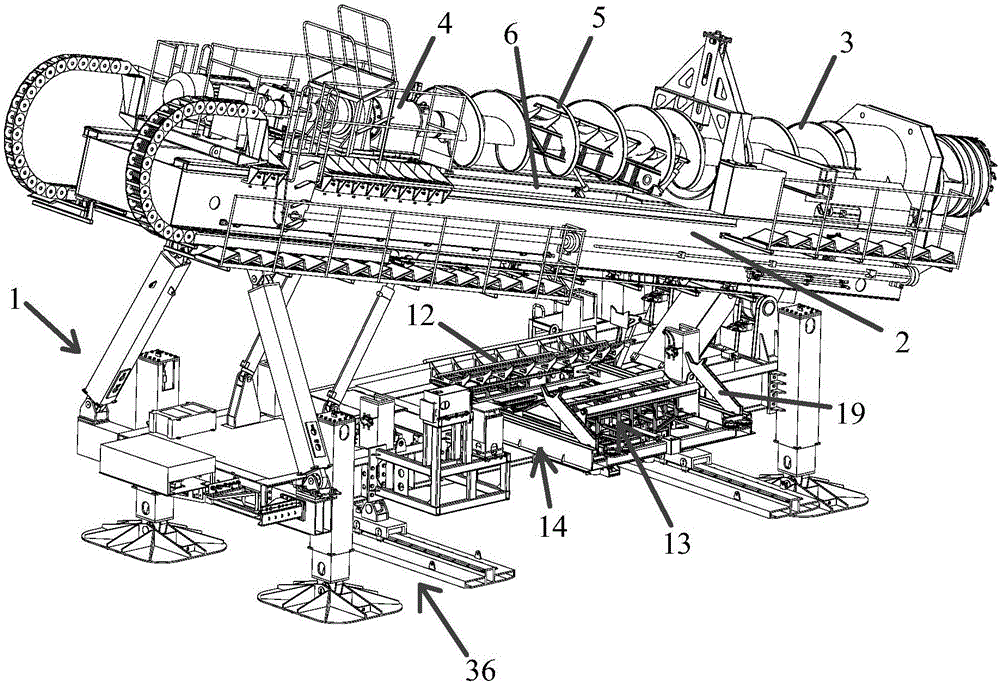

[0055] Independent claim 1 records an engineering drilling rig for automatically loading and unloading drill pipes, such as figure 1 and image 3 As shown, the engineering rig includes:

[0056] Rig body 1,

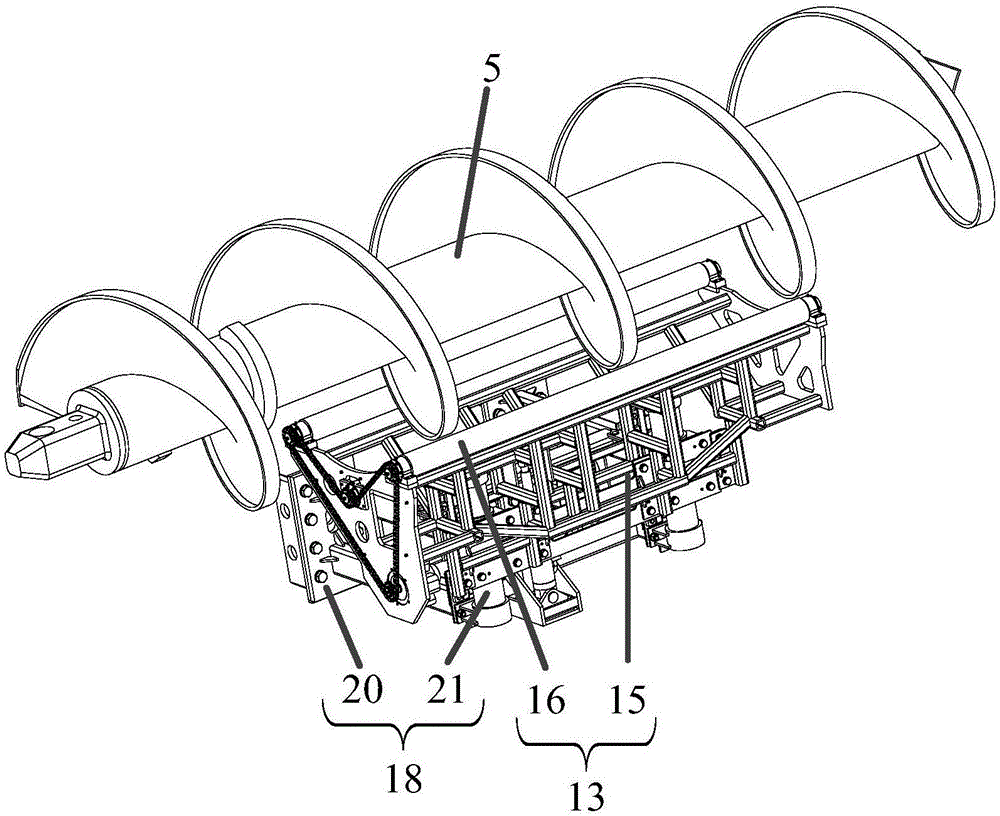

[0057] The drilling rig platform 2 is arranged on the drilling rig frame body 1 for placing the drill pipe 3 to be loaded and unloaded and the thruster 4, and the drilling rig platform corresponding to the position between the drill pipe 3 to be loaded and unloaded and the thruster 4 for placing the drill pipe 5 for loading and unloading 2 is provided with a loading and unloading drill pipe transfer channel 6;

[0058] The drill pipe angle and phase adjustment mechanism 13 is arranged at the bottom of the drilling rig platform 2, and is used to adjust the circumferential angle of the loading and unloading drill pipe 5 placed thereon;

[0059] The drill pipe horizontal transfer mechanism 14 is arranged at the bottom of the drilling rig platform 2, and is used to receiv...

Embodiment 2

[0090] An engineering drilling rig for automatically loading and unloading drill pipes, such as figure 1 and image 3 As shown, the engineering rig includes:

[0091] Rig body 1,

[0092] The drilling rig platform 2 is arranged on the drilling rig frame body 1 for placing the drill pipe 3 to be loaded and unloaded and the thruster 4, and the drilling rig platform corresponding to the position between the drill pipe 3 to be loaded and unloaded and the thruster 4 for placing the drill pipe 5 for loading and unloading 2 is provided with a loading and unloading drill pipe transfer channel 6;

[0093] The drill pipe angle and phase adjustment mechanism 13 is arranged at the bottom of the drilling rig platform 2, and is used to adjust the circumferential angle of the loading and unloading drill pipe 5 placed thereon;

[0094] The drill pipe horizontal transfer mechanism 14 is arranged at the bottom of the drilling rig platform 2, and is used to receive and move the loading and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com