Continuous coal mining machine end slope mining ventilation and dust removal system and method

A technology of dust removal system and coal mining machine, which is applied in mine/tunnel ventilation, dust prevention, mining equipment, etc. It can solve the problems that affect the normal operation of the electrical control system, difficult to control dust, and air pollution in the stope, so as to avoid burning Explosion accidents, increasing the area, and reducing the concentration of toxic and harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

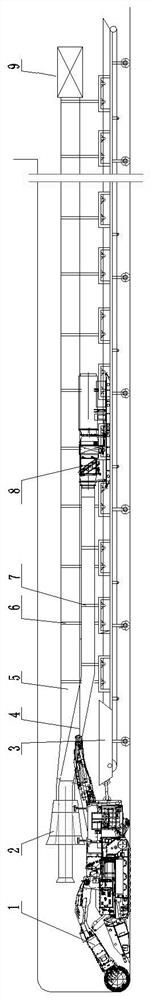

[0024] attached figure 1 It is a schematic diagram of the ventilating and dust-removing system for the end-side mining of the continuous coal mining machine of the present invention. It includes local ventilator 9, air supply duct 5, combined ventilation and dust control device 2, dust collector 8 and dust removal duct 4, which are arranged sequentially from the outside to the inside of the working surface, and one end of the air supply duct 5 is connected to the combined ventilation and dust control device. The device 2 is connected, one end is connected with the press-in local fan 9, and is arranged on the belt transportation system 3 through the suspension device 6, one end of the dust removal air cylinder 4 is connected with the combined ventilation and dust control device 2, and the other end is connected with the dust removal The dust collector 8 is connected, the dust removal air cylinder 4 and the dust collector 8 are arranged on the belt transportation system 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com