High-efficiency enhanced type lead wire continuity device

A splicing device and reinforced technology, applied in the direction of connecting contact material, connection with permanent deformation, multi-core cable end parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

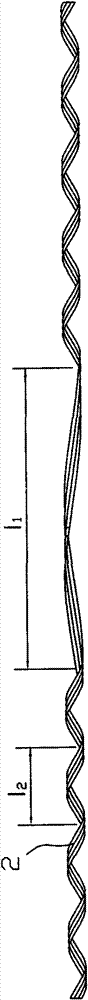

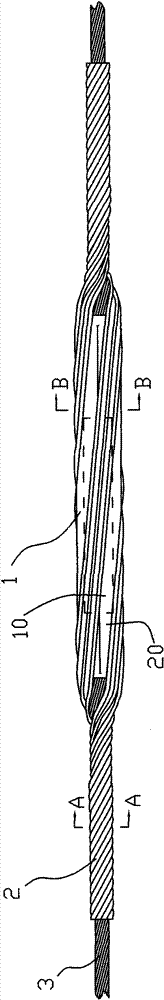

[0015] The invention as Figure 1-7 Shown: including crimping tube 1 and reinforcing pre-twisted wire, the crimping tube 1 connects the wire 3, and the reinforcing pre-twisted wire is wound and wrapped around the wire 3 and the crimping tube 1, 2-5 pieces The reinforcing pre-twisted wires are connected side by side as a whole, and then wound in a spiral shape to form a pre-twisted sub-bundle 2; the helical direction of the pre-twisted sub-bundle 2 is the same as that of the wire 3, and the pre-twisted The length of the sub-bundle 2 is 1.5-3 times that of the crimping tube 1, the two ends of the pre-twisted sub-bundle 2 beyond the crimping tube 1 have the same length; the pre-twisted sub-bundle 2 corresponds to the helical pitch of the crimping tube 1 part l 1 Consistent with the length of the crimping tube 1, the helical pitch two of the two parts of the two ends of the pre-twisted sub-bundle beyond the crimping tube is 5-50% of the helical pitch one. There are 2-5 pre-twist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com