Internal discharge process design method for period transition from metal strip mine mountain slope mining to deep concave mining

A technology of process design and mine slope, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of short strike length and difficult formation of inner discharge conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

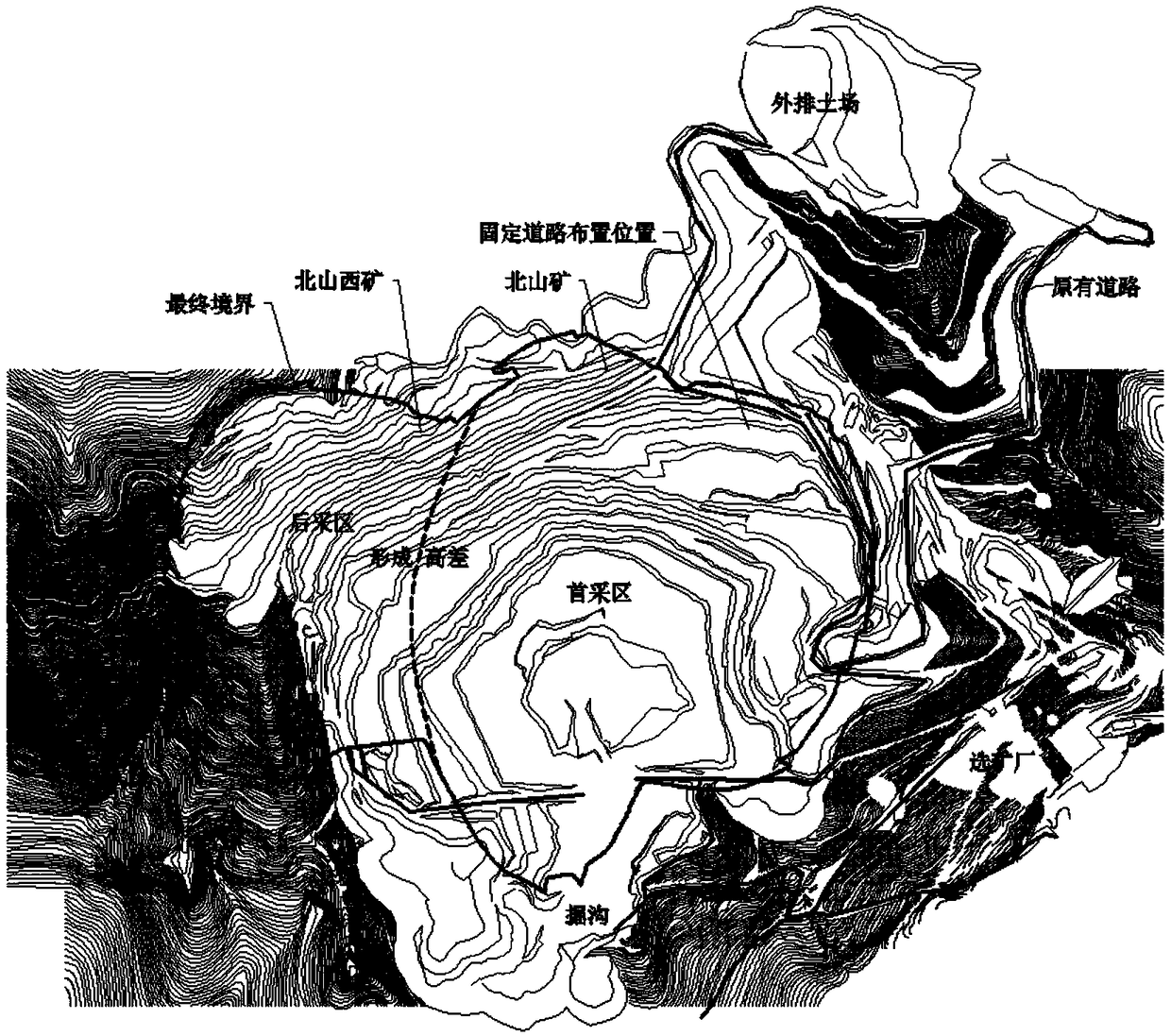

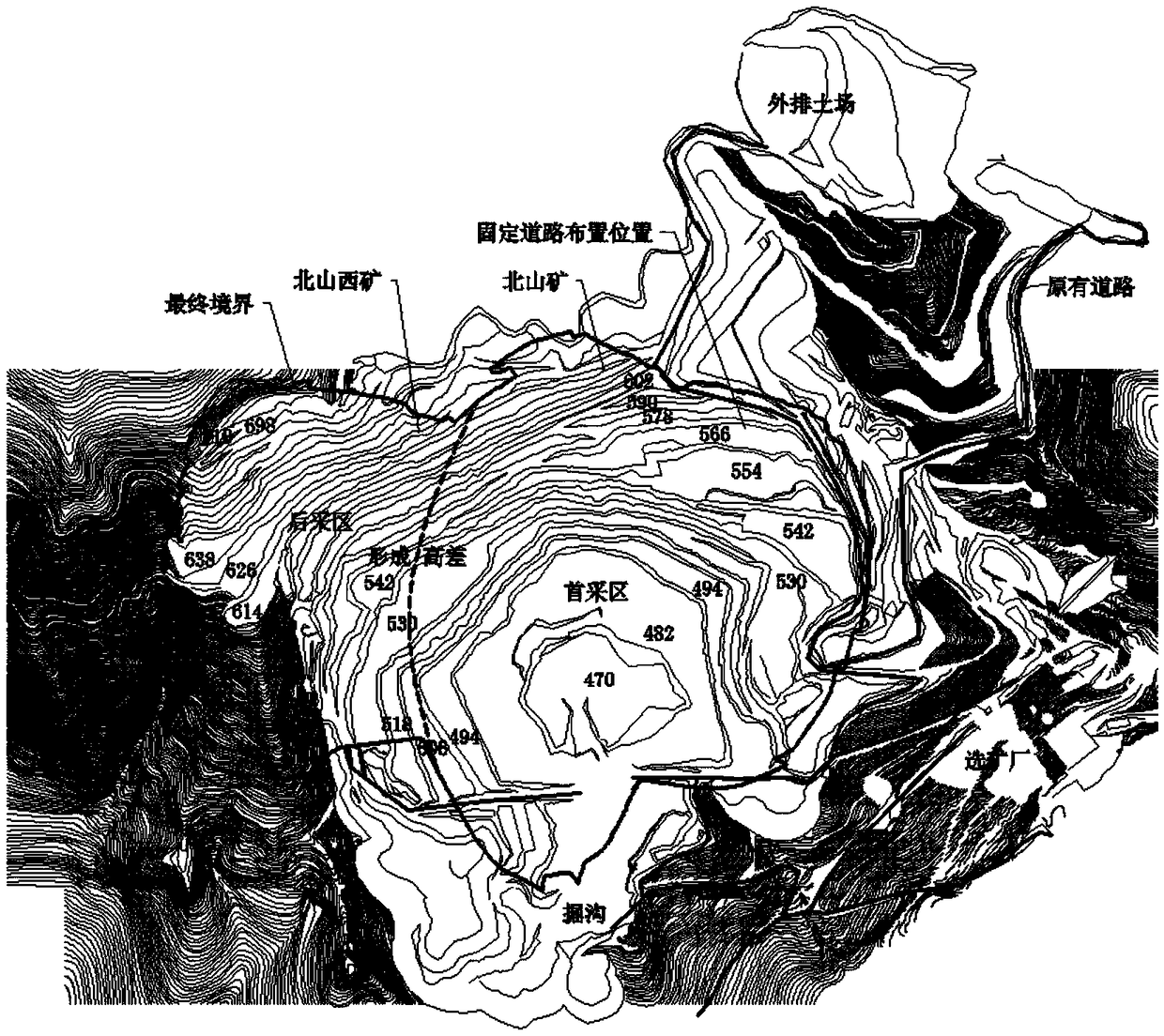

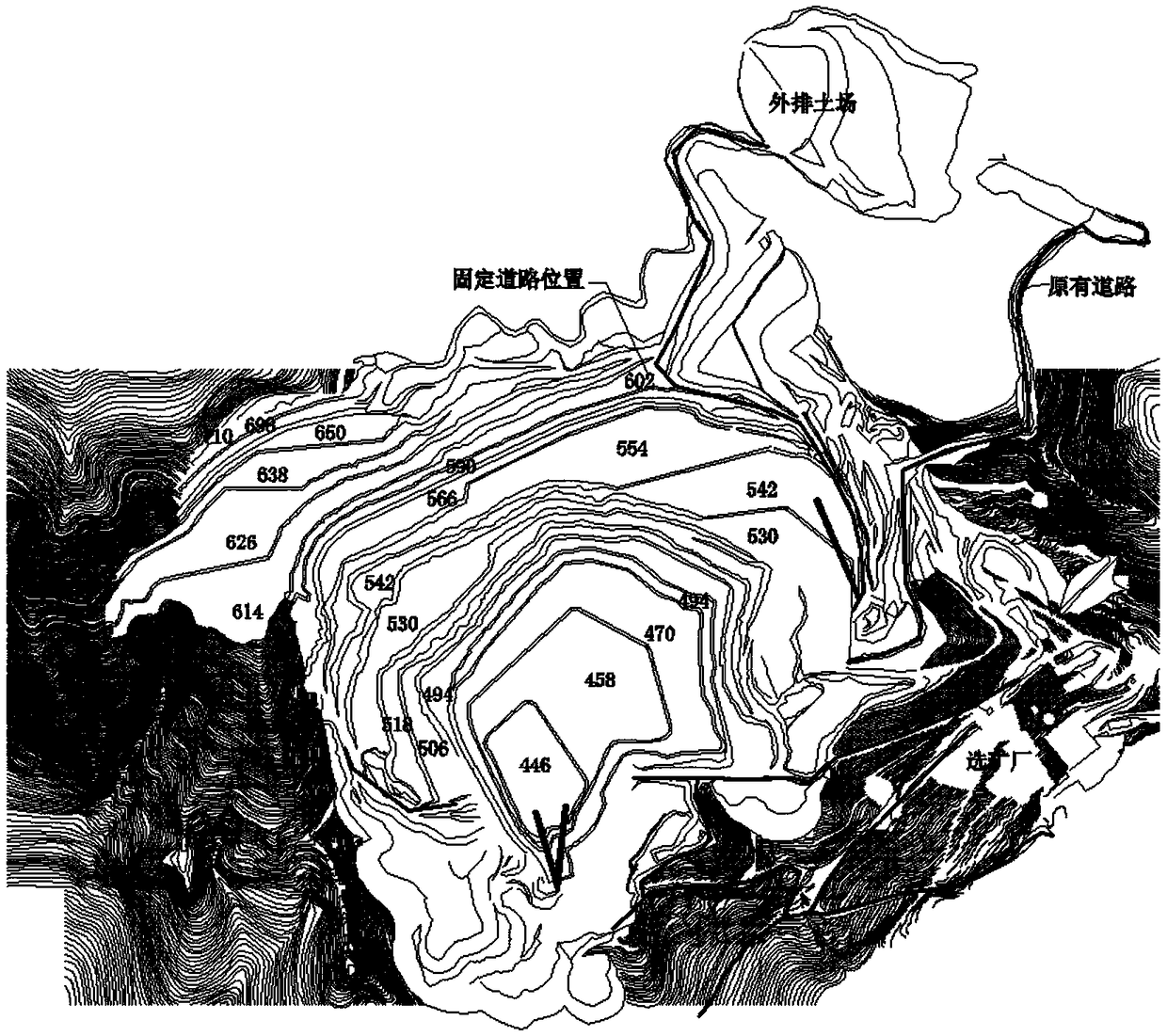

[0054] The working face of the open stope of this mine is arranged transversely to the trend of the ore body. It adopts medium and deep holes to strengthen loosening and blasting, hydraulic excavator shovel loading, and automobile transportation. The elevation of the lowest point of the open-pit stope slope is 470m (located in Beishan Mine), the highest elevation is 720m (located in Beishanxi Mine), and the relative elevation difference is 250m. Twenty steps are formed from the 710m platform on the upper edge of the Beishanxi Mine Gang to the 470m platform in the south of the mining area, with a height of 12m and a slope angle of 70-75°. At present, Beishan Mine has been mined to the level of 470m and has entered the sag open-pit mining.

[0055] like figure 2 As shown, the mines designed in this inner row are mainly divided into two mining areas, Beishan Mine and Beishanxi Mine. At present, the main stope is located in Beishan Mine, and part of Beishanxi Mine is less expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com