A dust removal device and dust removal method for side mining equipment

A dust removal device and equipment technology, applied to mining devices, mining equipment, safety devices, etc., to achieve the effect of reducing gas and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

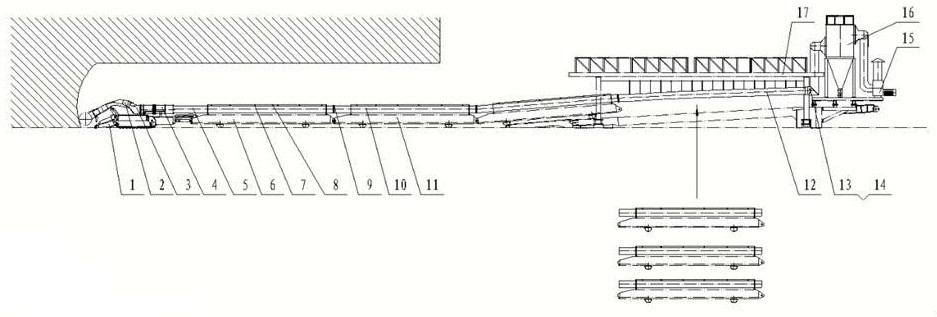

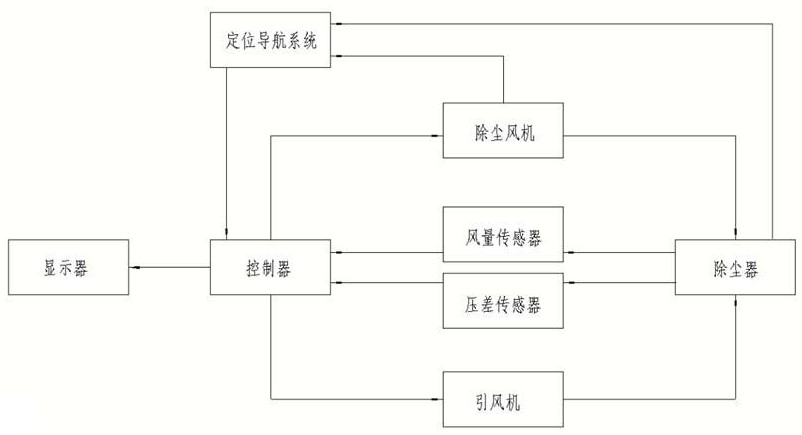

[0030] Such as figure 1 As shown, after the dust removal device is started, the dust removal fan 4 sucks the coal dust-containing gas from the air suction port of the bellows 2, and after being initially filtered by the filter device 18 of the transition section 3, it is blown along the first unit air duct 5 and each section of the standard unit air. The cylinder 10 and the telescopic air cylinder 12 are discharged to the dust collector 16. After filtering, the gas that meets the discharge requirements is discharged to the atmosphere through the induced draft fan 15. The standard unit blower 10 is connected with the standard transport unit 11 to or withdrawn from the transportation system to realize the increase or decrease of the total length of the blower, so that the total length of the blower can meet the requirements of adapting to different roadway depths.

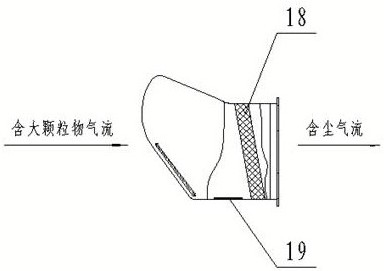

[0031] Such as figure 2 As shown, a filtering device 14 and a sewage outlet 15 are provided inside the transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com