Closed-cycle cooling system of continuous coal mining machine

A closed-loop, cooling system technology, used in cooling/ventilation devices, cooling/ventilation/heating retrofits, electromechanical devices, etc., can solve problems such as damage and rely on the roadway floor, and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

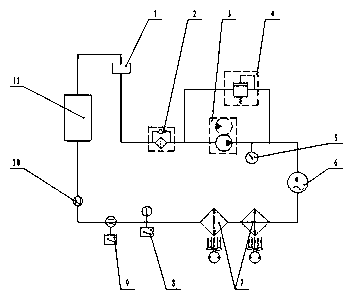

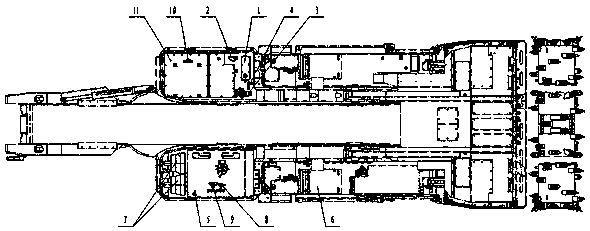

[0020] like Figure 4 As shown, after the continuous coal mining machine is started, the electromagnet 1TD on the radiator control valve group is energized by flipping the "circulating water" switch of the remote control, and the hydraulic oil drives the radiator ① to start and the water pump 3 to start, and the cooling water starts to flow along the Pipeline circulation, the water in the water tank 11 passes through the water supply tank 1 and the filter 2, and then is discharged by the water pump 3 to the water inlet of the water-cooled motor 6, and the hot water from the water outlet of the water-cooled motor 6 flows back to the water tank after being cooled by the cooling radiator 7 11. Reciprocating in this way; the outlet of the water pump 3 is provided with a safety valve 4 to prevent the pressure from exceeding the allowable range after being blocked, and to protect the system; the pressure gauge 5 can monitor the operating pressure of the cooling system in real time; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com