Method for planning dump of strip mine of ultra-thick inclined coal seam and efficiently recycling end slope resources

A recycling method and technology of dumping site, which can be applied in open-pit mining, earthwork drilling, mining equipment, etc., and can solve problems such as the impact of mine production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

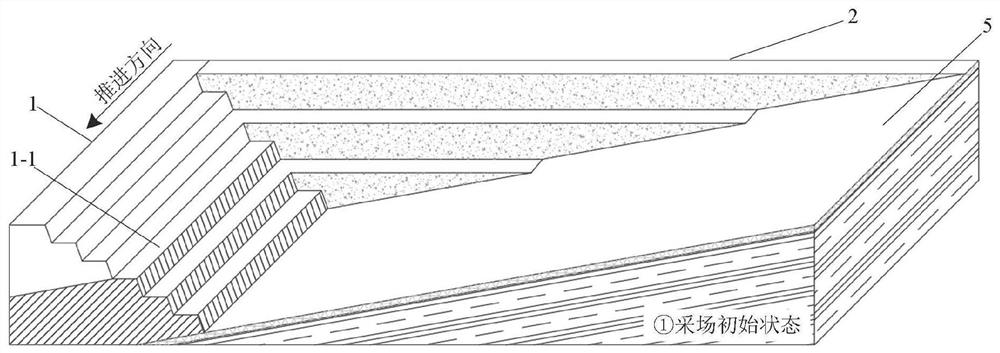

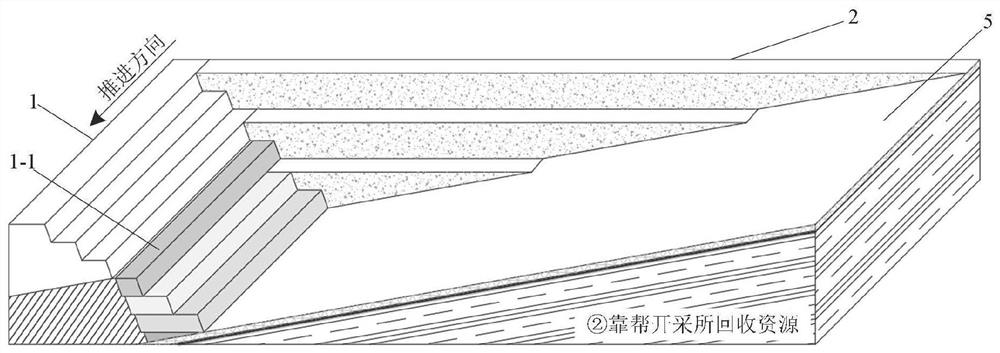

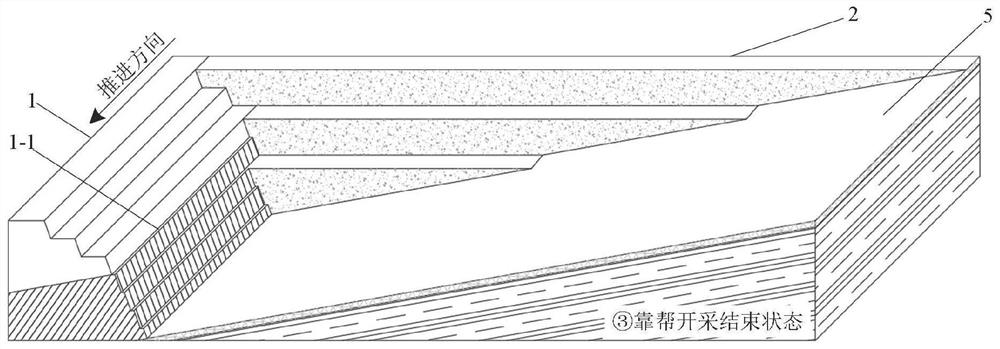

[0032] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0033] The method for planning the dump site 2 of the huge thick inclined coal seam open-pit mine and the resource efficient recovery method of the side wall 1 adopts the side wall 1 coal shearer 3 to mine the state of the huge thick coal seam open-pit mine after the edge mining is completed, The 1-1 part of the end side coal step is recovered by means of side mining; the huge thick coal seam is far greater than 4.60, so the method adopted and the change of the stope space position of the open-pit mine are different from the prior art. Similarly, the planning of the dump 2 refers to changing the dump 2 of the open-pit mine from the previous straight working line to the current broken line, providing a site for the mining of the end side 1 coal shearer 3; Efficient recovery of side 1 resources means that after side-by-side mining of side side 1 coal resources...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com