Gentle wall milling method at parallel milling area end under complex geological structure

A technology of complex geology and mining methods, applied in underground mining, surface mining, earth-moving drilling and other directions, can solve the problems of increasing mining costs, difficulty in achieving mineral output, increasing stripping equipment, etc., and achieves wide practicability and stable production. The effect of stripping ratio and reducing mining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

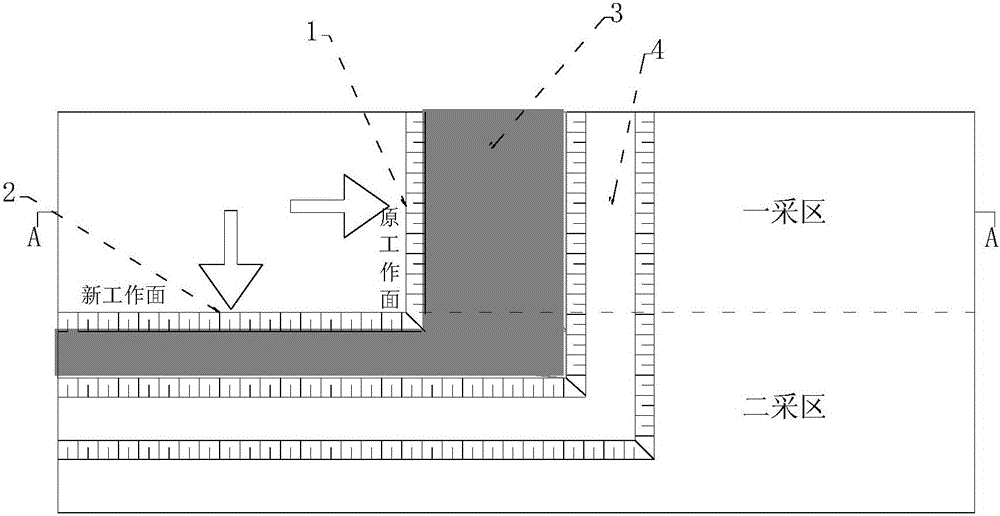

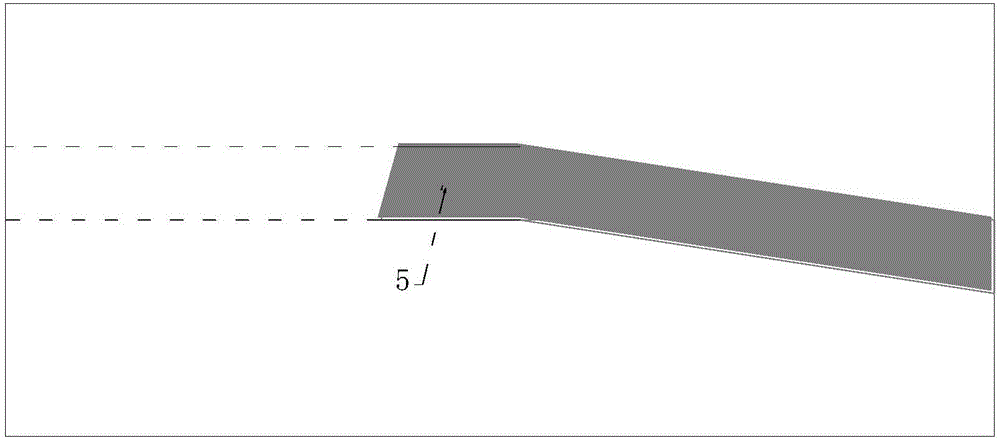

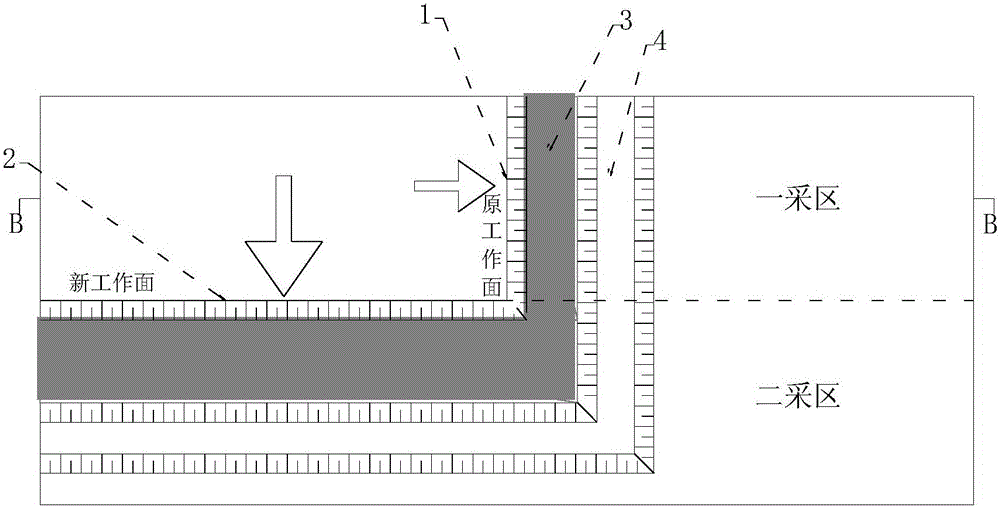

[0018] Such as figure 1 , figure 2 , image 3 Shown: In the case of complex geological structure, the end-side and slow-side mining method in the parallel mining area, the specific steps are as follows:

[0019] a. When the coal seam 5 in the open-pit mine changes from nearly horizontal to inclined downward along the advancing direction, the stripping step 4 is stripped in advance on the original coal mining face 1 in a mining area to obtain a large amount of recoverable coal;

[0020] b. Establish a new coal mining face 2 at the end and side of the original coal mining face 1, advance along the direction perpendicular to the original advancing direction of the coal mining face 1 in the first mining area, and open up a new mining area in the second mining area Coal working face 2, coal mining step 3 is mined at the same time, so that the two working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com