Quantitative evaluation method for water-resistant stripping performance of asphalt and aggregate

A water-stripping, asphalt mixture technology, applied in the direction of removing certain components such as weighing, measuring devices, analyzing materials, etc., can solve the problem that the comprehensive stripping of asphalt aggregates cannot be fully reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

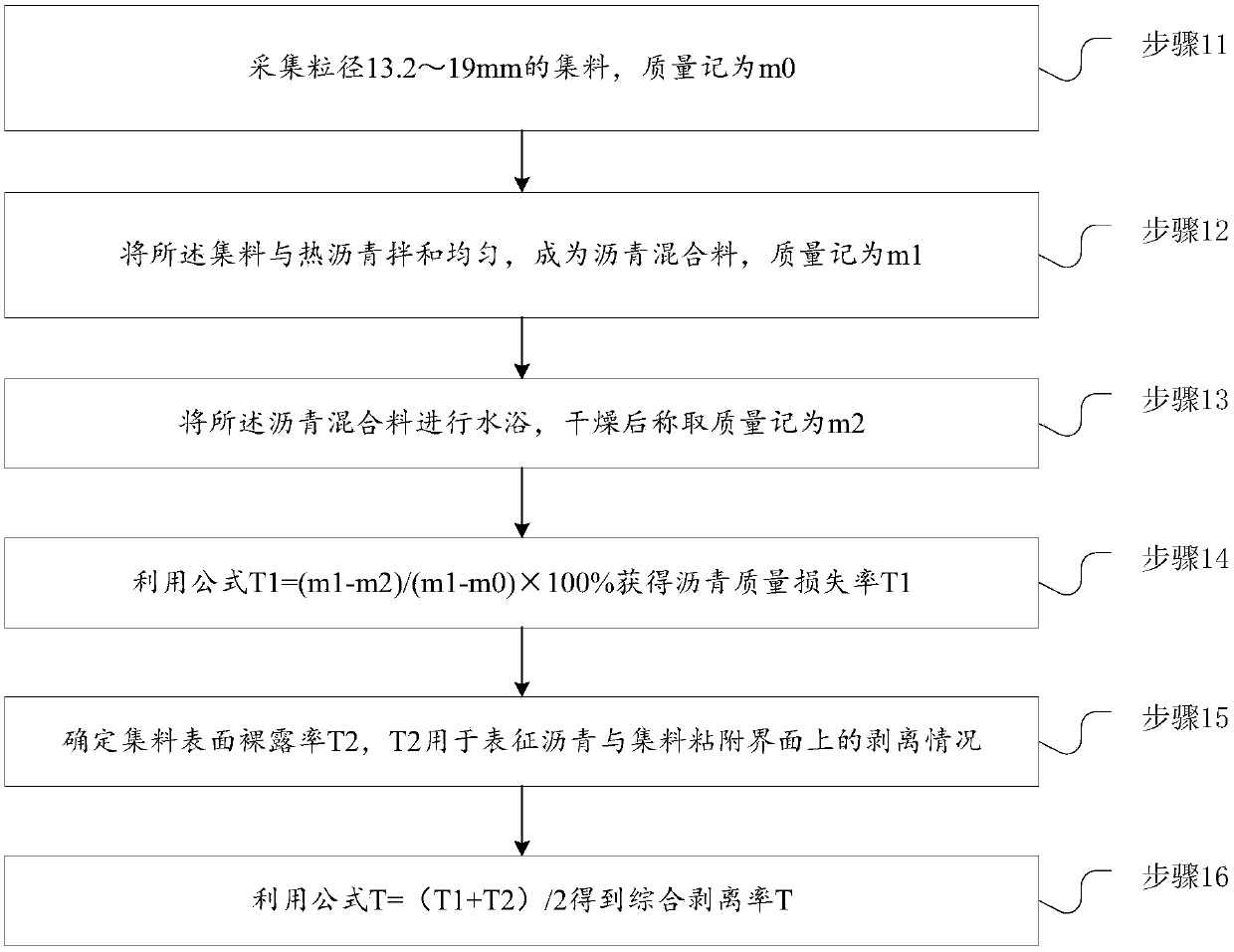

Method used

Image

Examples

Embodiment example

[0060] Implementation case: Select five common aggregates (basalt, limestone, diabase, hornshanite, broken gravel) and two kinds of matrix asphalt in road engineering, which are recorded as A and B respectively, and carry out the test according to the above steps.

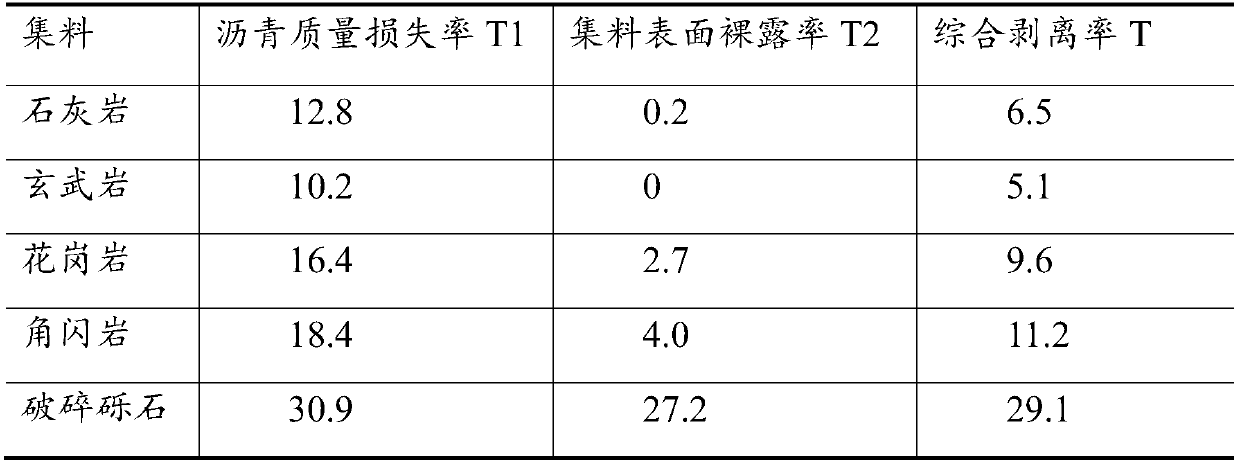

[0061] Table 1 A bitumen test results (%)

[0062]

[0063] Table 2 B asphalt test results (%)

[0064]

[0065]

[0066] It can be seen from the test results that no matter it is A or B asphalt, the ranking of the comprehensive stripping rates of the five aggregates is: basalt<limestone<granite<quartz sandstone<broken gravel, which shows that basalt has better water stripping resistance and broken gravel The water stripping performance is poor, which is consistent with the actual situation in the project.

[0067] In the test results of asphalt B, the bare areas of basalt, limestone, and granite surfaces are all close to 0%, and it is difficult to evaluate the performance of water stripping by observing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com