Open-pit mining method for triangular ore quantity between layered flat deposit strip areas

A technology for open-pit mining and triangular mining, which is applied in surface mining, earth-moving drilling, underground mining, etc., can solve problems such as the decline of overall economic benefits and the increase of the average stripping ratio of mines, so as to improve early-stage economic benefits and increase early-stage economic benefits. , the effect of improving the resource recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

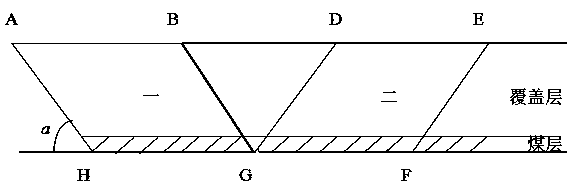

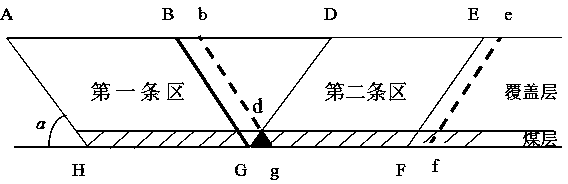

[0016] In the process of open-pit mining of layered near-horizontal deposits, the deposit is first divided into several parallel mining strips according to the strike. During normal operation, the former section is excavated first and then backfilled, and the subsequent strips are excavated and then backfilled. Such as figure 1 As shown in Fig. 1, the subsequent strip partially overlaps with the previous strip in the cross-section during mining, and the overlapping area is the amount of secondary repeated stripping. In order to reduce the amount of repeated stripping and the average stripping ratio of the mine and improve the overall economic benefits of the mine, the method of reducing the amount of repeated stripping can be adopted, that is, the sides of the overlapping areas of the two adjacent strips before and after the design intersect at the overburden and the coal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com