Optimization method for slant-basement inner-dumping-site side slope shapes

An optimization method and technology for dumping sites, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of failing to maximize economic benefits, increasing stripping distance, and not effectively utilizing land resources, etc. problems, to save the cost of open-pit mining and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

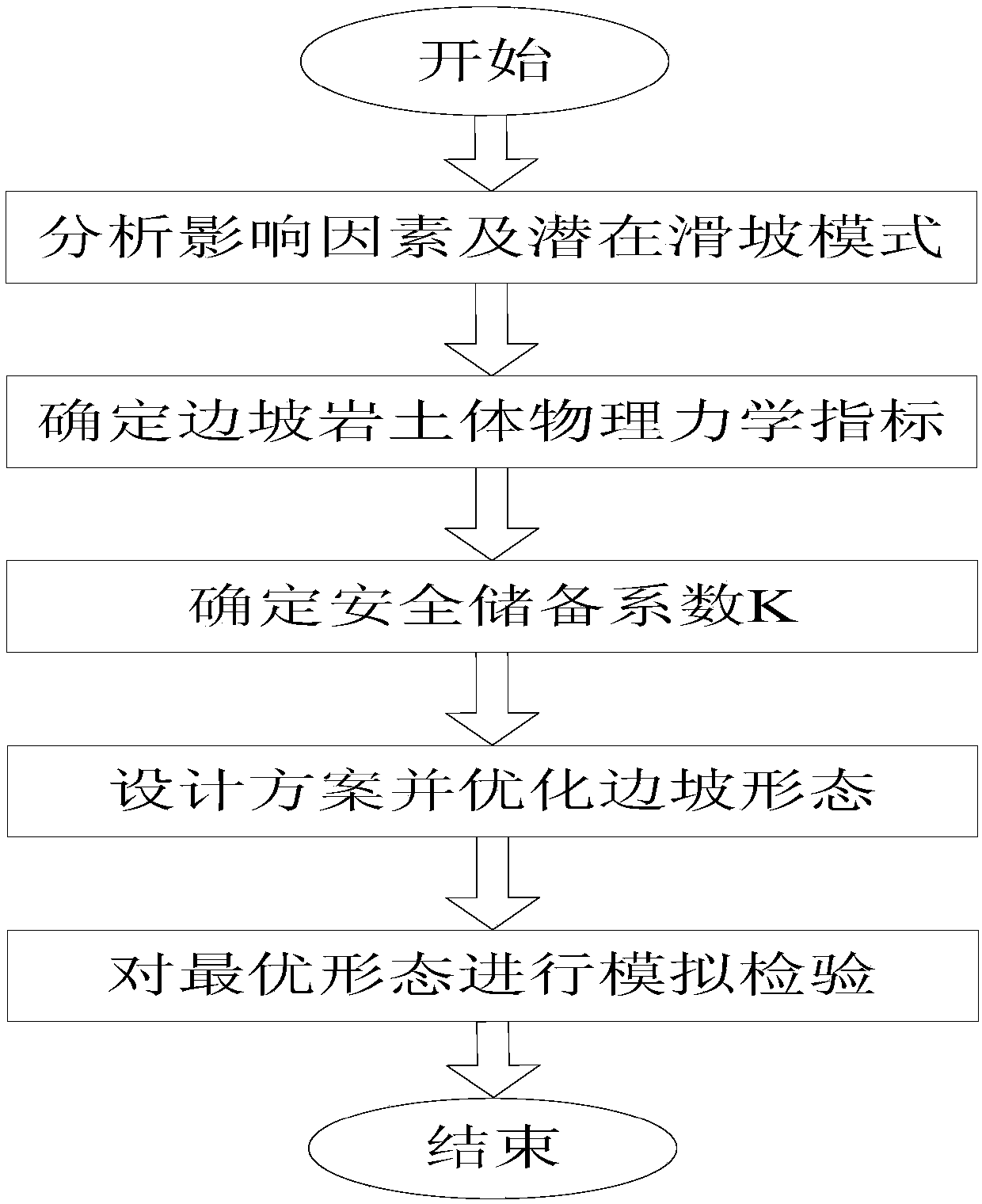

Method used

Image

Examples

Embodiment 1

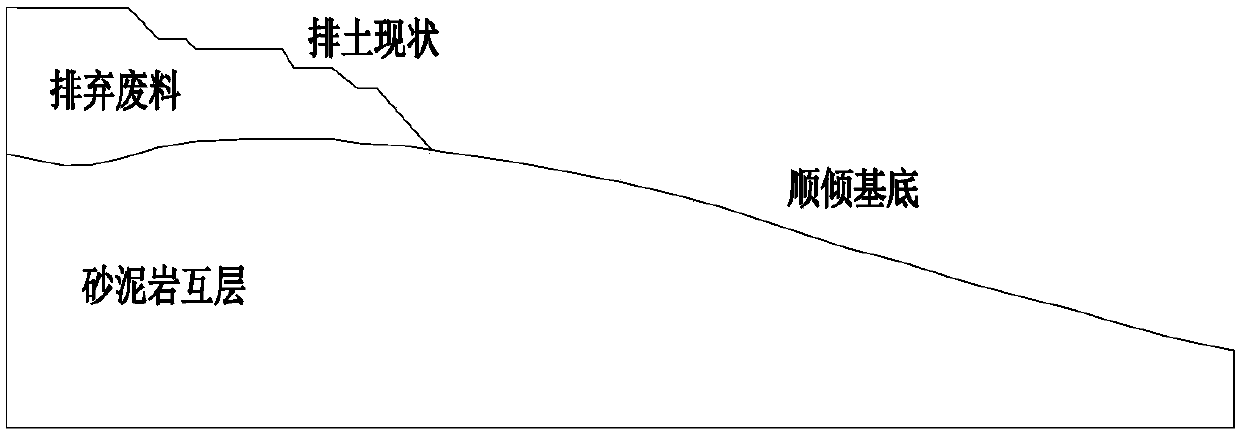

[0039] There is an anticline geological structure in an open-pit mining area, and the inner dump just advances to the top of the anticline axis. The width of the anticline structure area is 1200m, and the direction is SE-NW. Due to the influence of the anticline structure, the drop of the coal seam reaches 270m, but the ground surface and the bedrock surface drop less than 100m. The coal seam transitions from a near-horizontal coal seam to an inclined coal seam. The inclination angle of the coal seam floor is large, resulting in the slope base of the inner dump site being inclined and stable. The performance is greatly affected, and at the same time, due to the increase in the amount of stripping, a larger space for soil discharge needs to be released. figure 2 It is a schematic diagram of the inclined base of the internal dump.

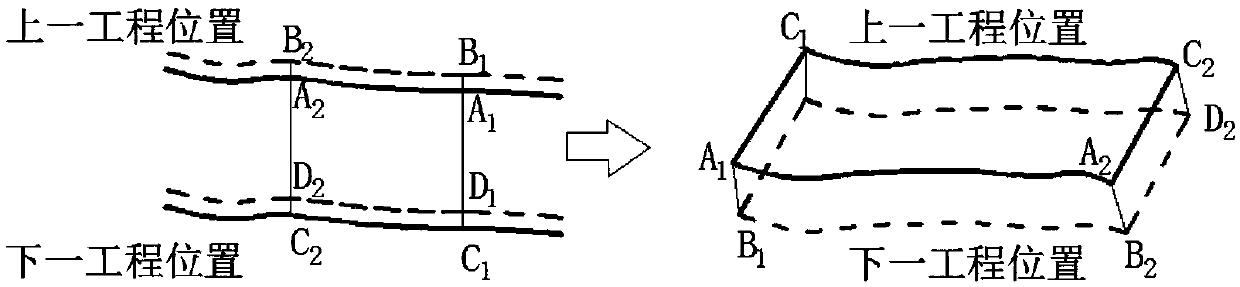

[0040] The current situation of the dump dump in the example open-pit mine has reached the level of 1420, and the specific steps of using the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com