Opencast coal mine end slope filling mining method

A technology for open-pit coal mines and mining methods, which is applied to the mining, filling, and mining equipment of open-pit mines. It can solve problems such as waste of resources, instability of safe coal pillars, and water and soil pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] The side filling mining method of the open-pit coal mine of the present invention:

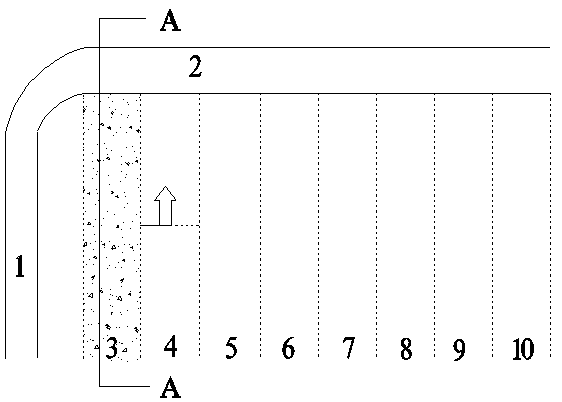

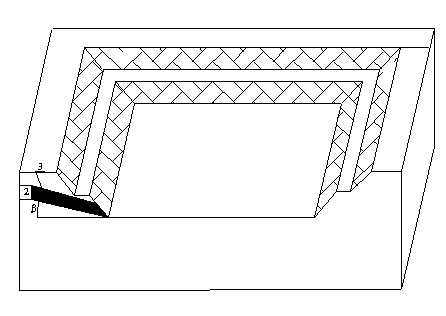

[0019] a. Divide the safety coal pillar left on the side of the open-pit coal mine into multiple coal rooms equal to the width of the side-wall shearer drum, such as figure 1 As shown, coal houses 3, 4, 5, 6, 7, 8, 9, 10;

[0020] b. Drill filling roadway 1 along the direction of the coal seam to the safety boundary of the surface, then dig the filling roadway 2 along the inclined direction of the coal seam, digging the filling roadway 2 in the inclined direction with a width of 4.0 m and a height of 3.0 m, and then lay filling pipelines in the filling roadway;

[0021] c. Excavate and fill roadway 2 in the inclined direction from the coal seam, use the end-side shearer to mine multiple coal rooms at intervals, such as coal rooms 3, 5, 7, and 9, and the width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com