Method for recovering coal in easily sliding area of strip mine

A recycling method and technology for open-pit mines, which are used in surface mining, earth-moving drilling, and underground mining, etc., can solve the problems of waste of coal resources in open-pit mines, low overall efficiency of the mining area, and endanger the safety of personnel and equipment, etc. Wide practicability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

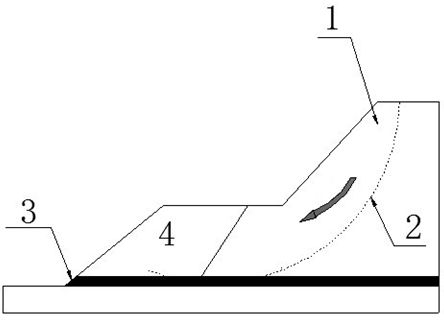

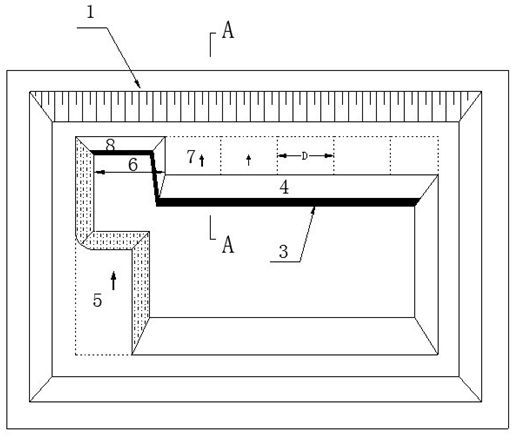

[0019] Embodiment one, as figure 2 , 3 Shown: Divide the edge 1 in the easy-slip area into several mining strips according to the direction, and the width of each mining strip is twice the working radius of the electric shovel; starting from the side of the edge 1 in the easy-slip area, first strip The rock mass 4 of the first mining strip 6 is then advanced along the vertical slope to recover the coal 3 of the first mining strip 6, and the internal dump site 5 is followed up in time to clean and remove the stripped rock mass 4 materials in time. Be transported to the inner dump site 5 for disposal, and the coal 3 recovered from the first mining strip 6 will be transported out by transportation equipment; after the first mining strip 6 is finished, the rock mass 4 of the second mining strip 7 will be stripped, Recover the coal 3 in the second mining zone 7, follow up in the inner dump site 5, and cover the stripped rock mass 4 material in the first mining zone 6 until the ex...

Embodiment 2

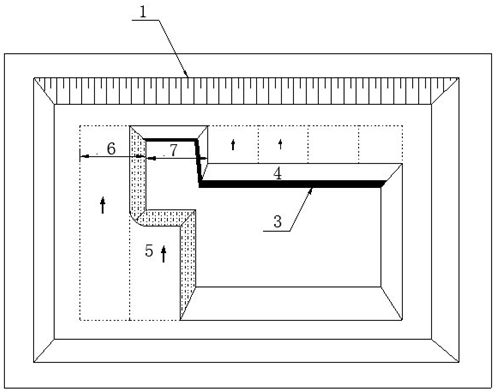

[0020] Embodiment two, basically the same as embodiment one, as Figure 4 , 5 Shown: Divide the edge 1 in the easy-slip area into several mining strips according to the direction, and the width of each mining strip is twice the working radius of the electric shovel; starting from the side of the edge 1 in the easy-slip area, first strip The rock mass 4 of the first mining strip 6 is advanced along the side slope to reclaim the coal 3 of the first mining strip 6, and the inner dump site 5 is followed up in time; The rock mass 4 of the second mining strip 7 reclaims the coal 3 of the second mining strip 7, and the inner dump site 5 follows up and covers the exposed surface 8 after the first mining strip 6 is mined to the boundary; All the mining strips after the strip 7 are mined one by one, the rock mass 4 is stripped first, and then the coal 3 is recovered, and the inner dump site 5 covers the exposed surface 8 after the mining of the previous mining strip to the boundary in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com