Preparation method of high-concentration MoS2 nanosheet

A nanosheet, high-concentration technology, applied in the field of preparation of high-concentration MoS2 nanosheets, can solve problems such as limiting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

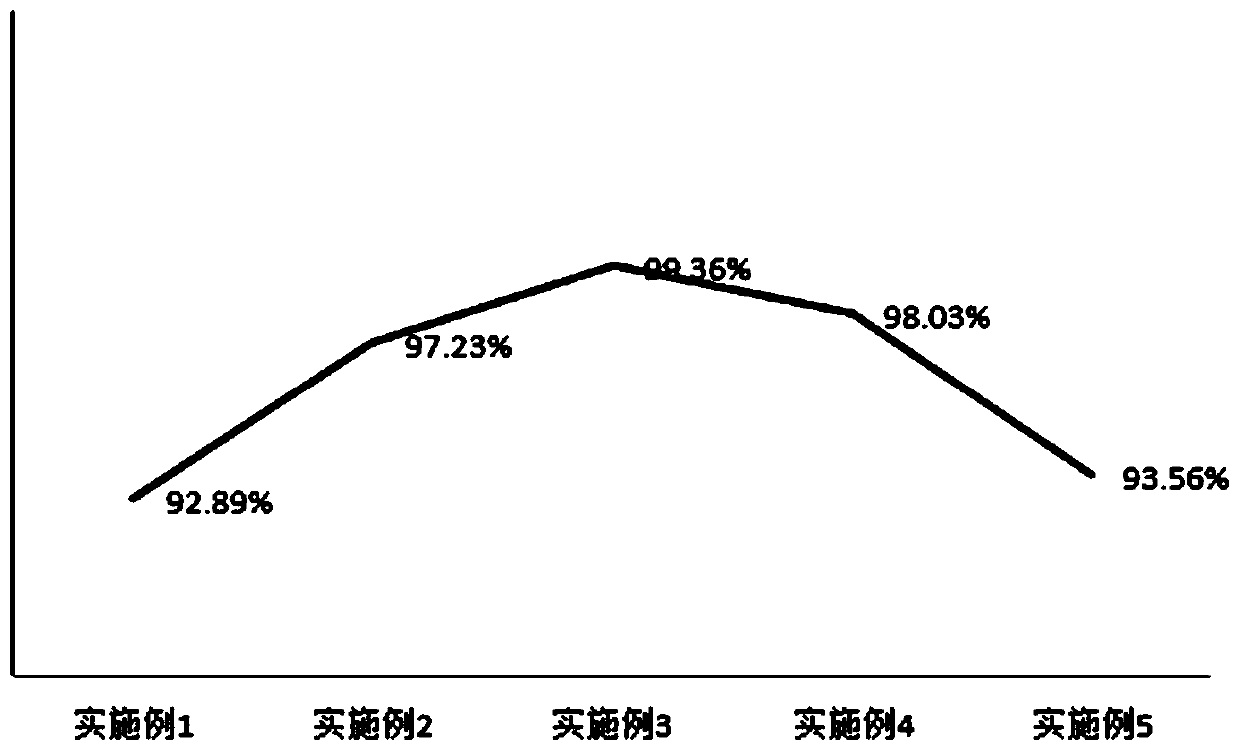

Embodiment 1

[0043] A high concentration MoS 2 The method for preparing nanosheets specifically includes the following steps: Step S1: adding 5 g of molybdenum disulfide single crystal blocks with a particle size of 10-30 μm and a purity greater than 99.95% into a closed ultrasonic bottle with a blue cap, and then pouring Add 20% ethanol and 80% water mixed solvent 325ml into the ultrasonic bottle to form a solution system;

[0044] Step S2: performing argon or nitrogen bubbling treatment on the solution system in the blue cap ultrasonic bottle, and the bubbling treatment adopts the prior art;

[0045] Step S3: Put the blue cap ultrasonic bottle into the ultrasonic cleaning machine for ultrasonic treatment. The ultrasonic conditions are: ultrasonic power is 320W, ultrasonic time is 40min; during ultrasonic treatment, ice cubes are added to the ultrasonic cleaning machine to create a low-temperature environment and serve as an ice bath Cooling effect, get dark green MoS2 nanosheet dispersion...

Embodiment 2

[0052] The difference between this example and Example 1 is that in step S1: 5g of molybdenum disulfide single crystal block with a particle size of 10-30 μm and a purity greater than 99.95% is added to a closed ultrasonic bottle with a blue cap, and then The volume fraction of 20% ethanol and 80% water mixed solvent 350ml was added to the ultrasonic bottle with blue cap to form a solution system; others were the same as in Example 1.

Embodiment 3

[0054] The difference between this example and Example 1 is that in step S1: 5g of molybdenum disulfide single crystal block with a particle size of 10-30 μm and a purity greater than 99.95% is added to a closed ultrasonic bottle with a blue cap, and then The volume fraction of 20% ethanol and 80% water mixed solvent 500ml was added to the ultrasonic bottle with blue cap to form a solution system; others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com