Open-pit coal mine double-pit dynamic stripping ratio adjusting method

An adjustment method and open-pit coal mine technology, which is applied in open-pit mining, earthwork drilling, special mining, etc., can solve problems such as changes in the stripping ratio and the inability to effectively strip and adjust the advanced stripping method, and achieve large adjustment capabilities, The effect of wide application value and flexible adjustment mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

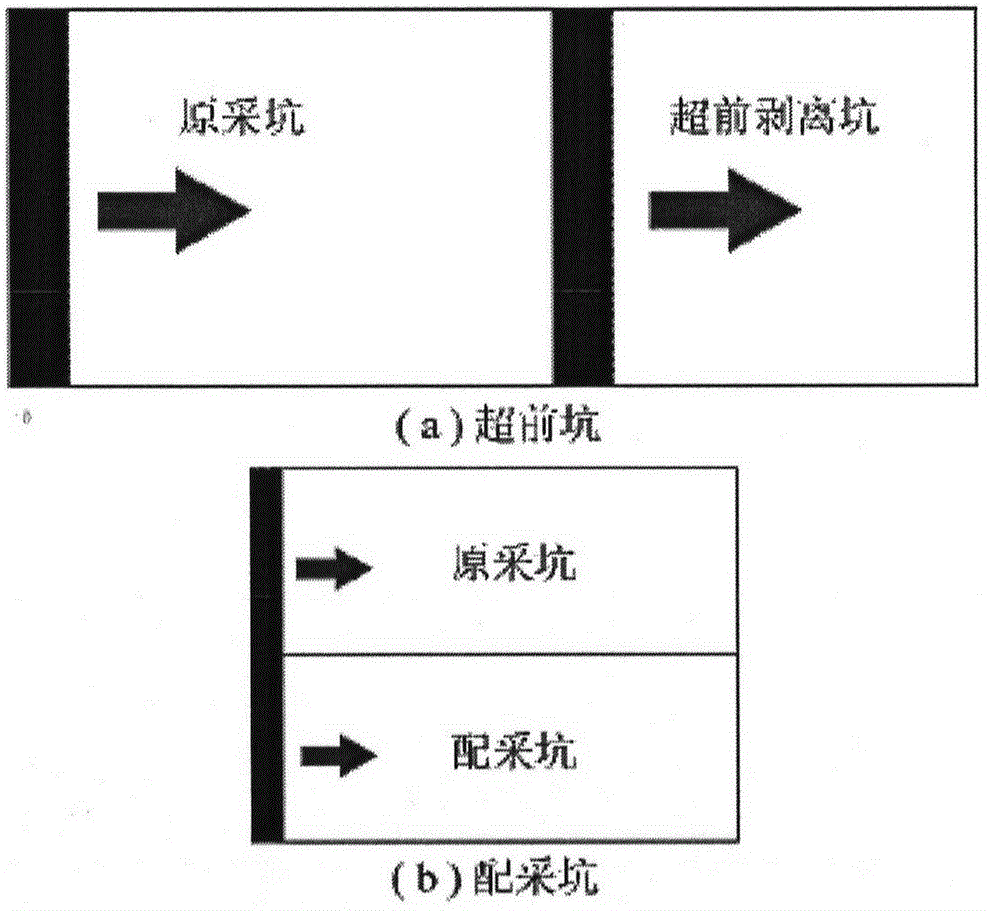

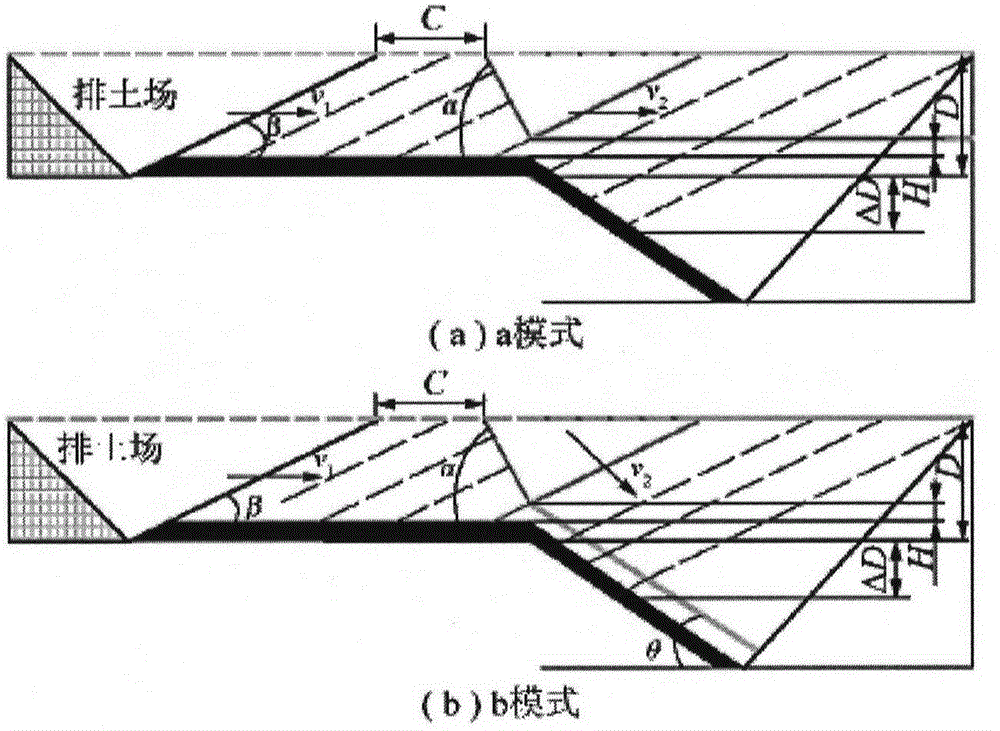

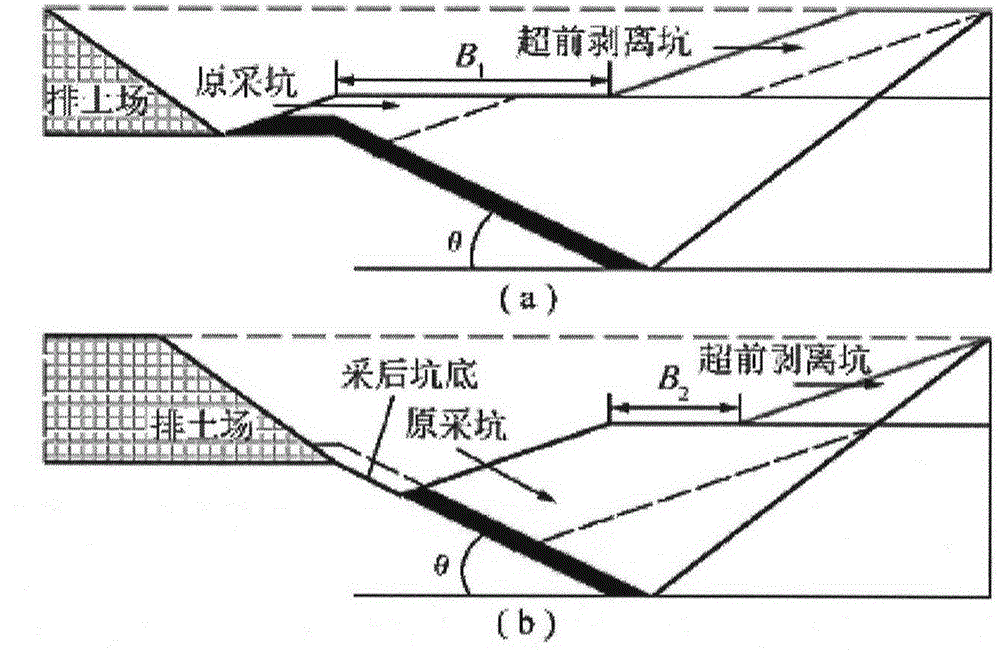

[0014] According to the geological conditions and mining conditions of each open-pit coal mine, different adjustment modes in the present invention are selected. For near-horizontal and inclined coal seams, the adjustment mode of the original mining pit and the advanced pit is generally used, and the trench is deepened in the area with a relatively high stripping ratio in the advancing direction to open up a new advanced stripping stope. Such as figure 1 (a). This mode also includes two modes, such as figure 2 shown. figure 2 Among them, D is the mining depth of the open-pit mine, m; OD is the depth of the coal seam drop, m; H is the distance from the bottom of the advanced stripping pit to the roof of the coal seam, m; β is the working slope angle of the original mining pit, (°); is the side slope angle at the end of the advanced stripping pit, (°); C is the surface distance between the two pits, m; v 1 Propelling speed for the original mining pit, m / a; v 2 Propelling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com