Processing method of Taoyuan big leaf dark tea

A technology of Taoyuan big leaf and processing method, which is applied in the processing field of Taoyuan big leaf tea and dark tea, can solve the problems of long accumulation time and difficult quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

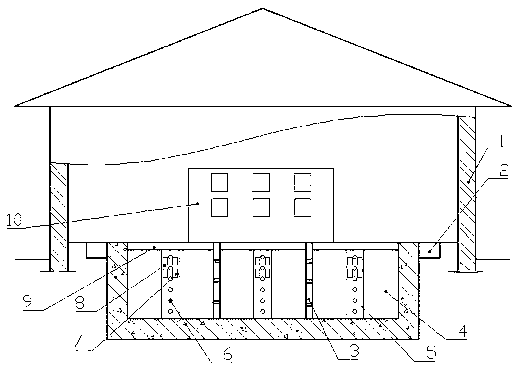

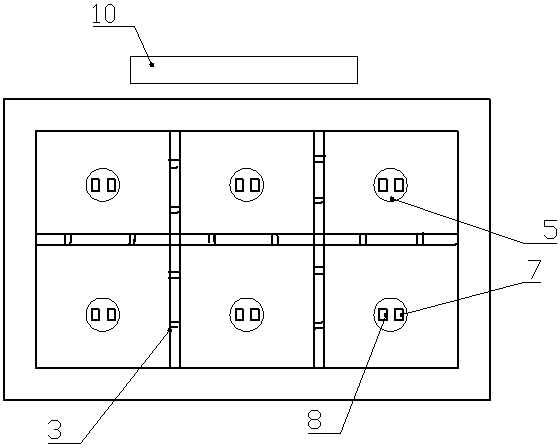

[0015] This processing method of Taoyuan big-leaf tea black tea takes one bud and three leaves of Taoyuan big-leaf tea as raw material, and after curing, the curing time: 4 minutes; it is required that the leaf surface loses luster, the leaf quality becomes soft, slightly sticky, and the tea stem is not easy to break , the leaf color changes from green to dark green, and emits a certain fragrance; then knead to make the leaves initially strips, and the tea juice is kneaded out and adhered to the surface of the leaves, creating conditions for the heap; after kneading: the leaf cell damage rate 35%, the strip rate of tea leaves is more than 90%, the rope is tightly rolled, and the tea juice is fully overflowed. When the hands are held tightly, the tea juice can be squeezed out from the fingers. It is carried out in a stack cellar, and then baked and dried after stacking to obtain a finished product.

[0016] The tea pile cellar is to dig a 1m deep and 3m long rectangular cellar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com