Preparation method of precursor iron phosphate of cathode material lithium iron phosphate of lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as harsh production conditions, difficult control of product components, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Weigh 55.604g of ferrous sulfate heptahydrate, weigh 23.004g of ammonium dihydrogen phosphate, dissolve it in 0.2L deionized water respectively, stir to dissolve it; mix ferrous sulfate solution and ammonium dihydrogen phosphate solution At the same time, it was added to the reactor at a speed of 800mL / h, and the stirrer was turned on for strong stirring. The reaction temperature was controlled at 80°C, and the reaction time was 0.5h under the condition of a stirring speed of 800r / min, and gray ferrous phosphate was obtained. suspension;

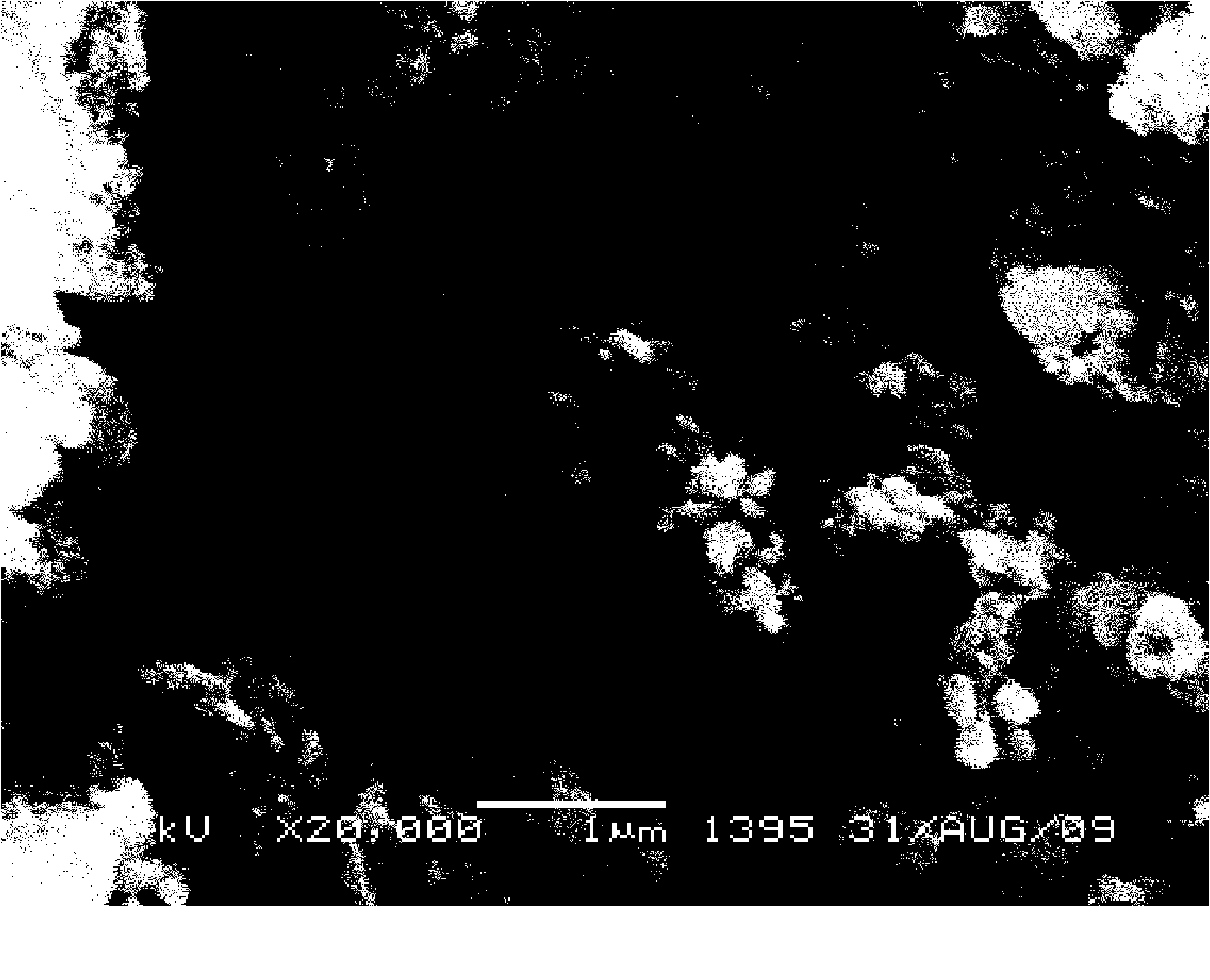

[0016] (2) Take 11.4 mL of hydrogen peroxide and add it to the above suspension, a large amount of white precipitates will appear immediately, continue to react for 0.5 h, and after aging for 6 h, filter and wash repeatedly to obtain the precipitate iron phosphate, which is white in color. The total iron content (Fe) of gained ferric phosphate is 29.8%, P is 16.5%, particle diameter is about 300nm, D 50 = 2.5 μm.

[0017] (3) Pu...

Embodiment 2

[0019] (1) Weigh 55.604g of ferrous sulfate heptahydrate, weigh 23.004g of ammonium dihydrogen phosphate, dissolve it in 2L of deionized water respectively, stir to dissolve it; mix ferrous sulfate solution and ammonium dihydrogen phosphate solution simultaneously Add it into the reactor at a speed of 600mL / h, and turn on the stirrer for strong stirring, control the reaction temperature at 60°C, and under the condition of stirring speed of 1000r / min, the reaction time is 1h to obtain light gray ferrous phosphate suspension;

[0020] (2) Take 15.6 mL of hydrogen peroxide and add it to the above suspension, a large amount of white precipitates will appear immediately, continue to react for 1 hour, and after aging for 8 hours, filter and wash repeatedly to obtain precipitated ferric phosphate, which is light yellow in color. The total iron content (Fe) of gained ferric phosphate is 31.8%, and P is 17.2%, and particle size is about 100nm, D 50 = 1.8 μm.

[0021] (3) Put the iron...

Embodiment 3

[0023] (1) Weigh 55.604g of ferrous sulfate heptahydrate, weigh 23.004g of ammonium dihydrogen phosphate, dissolve it in 0.1L deionized water respectively, stir to dissolve it; mix ferrous sulfate solution and ammonium dihydrogen phosphate solution At the same time, it was added to the reactor at a speed of 1000mL / h, and the stirrer was turned on for stirring, and the reaction temperature was controlled to be 90°C. Under the condition of a stirring speed of 600r / min, the reaction time was 0.3h, and light gray ferrous phosphate was obtained. suspension;

[0024] (2) Take 11.4mL of hydrogen peroxide and add it to the above suspension, a large amount of white precipitates will appear immediately, continue to react for 0.3h, and after aging for 4h, filter and wash repeatedly to obtain precipitate iron phosphate, which is white in color. The total iron content (Fe) of the obtained ferric phosphate is 25.2%, P is 13.7%, particle size is about 1 μm, D 50 = 4.3 μm.

[0025] (3) Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com