Process for producing nano-scale W-Cu composite powder with even dispersion

A uniform dispersion and nanoscale technology, which is applied in the field of metal materials, can solve the problems that the composite powder is difficult to achieve uniform dispersion at the nanoscale, and achieve the effects of less equipment investment, simple process control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

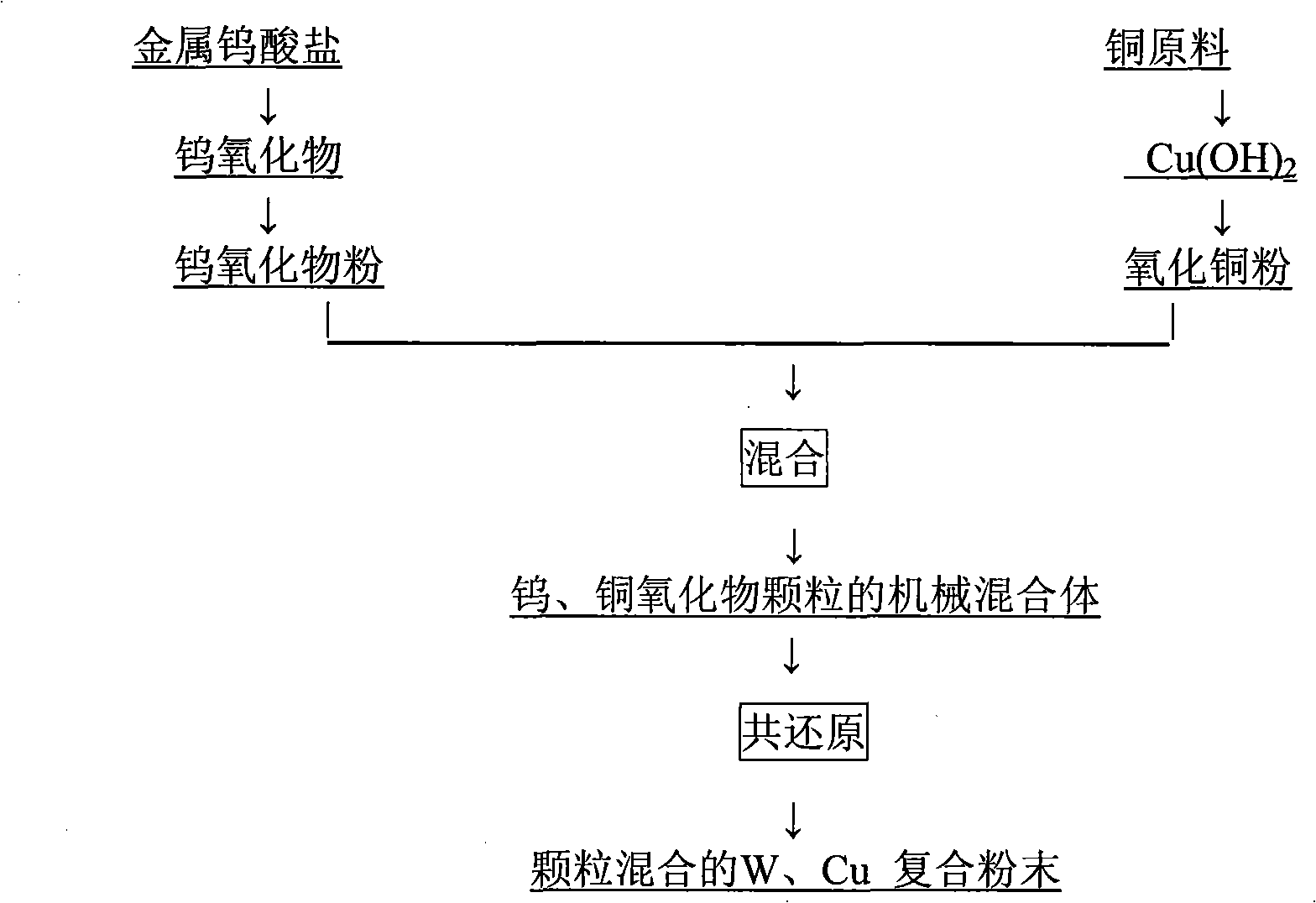

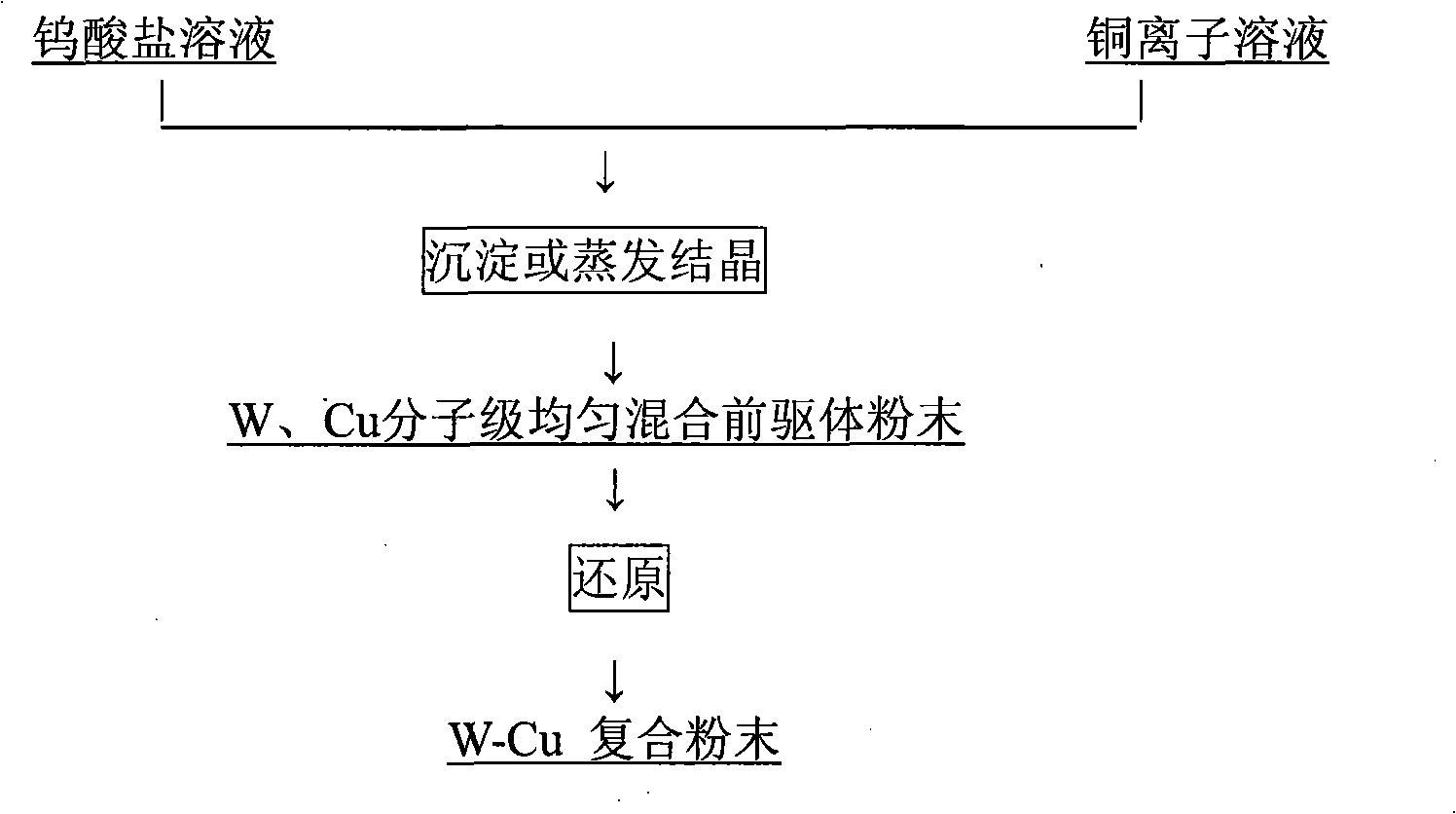

Problems solved by technology

Method used

Image

Examples

Embodiment 1

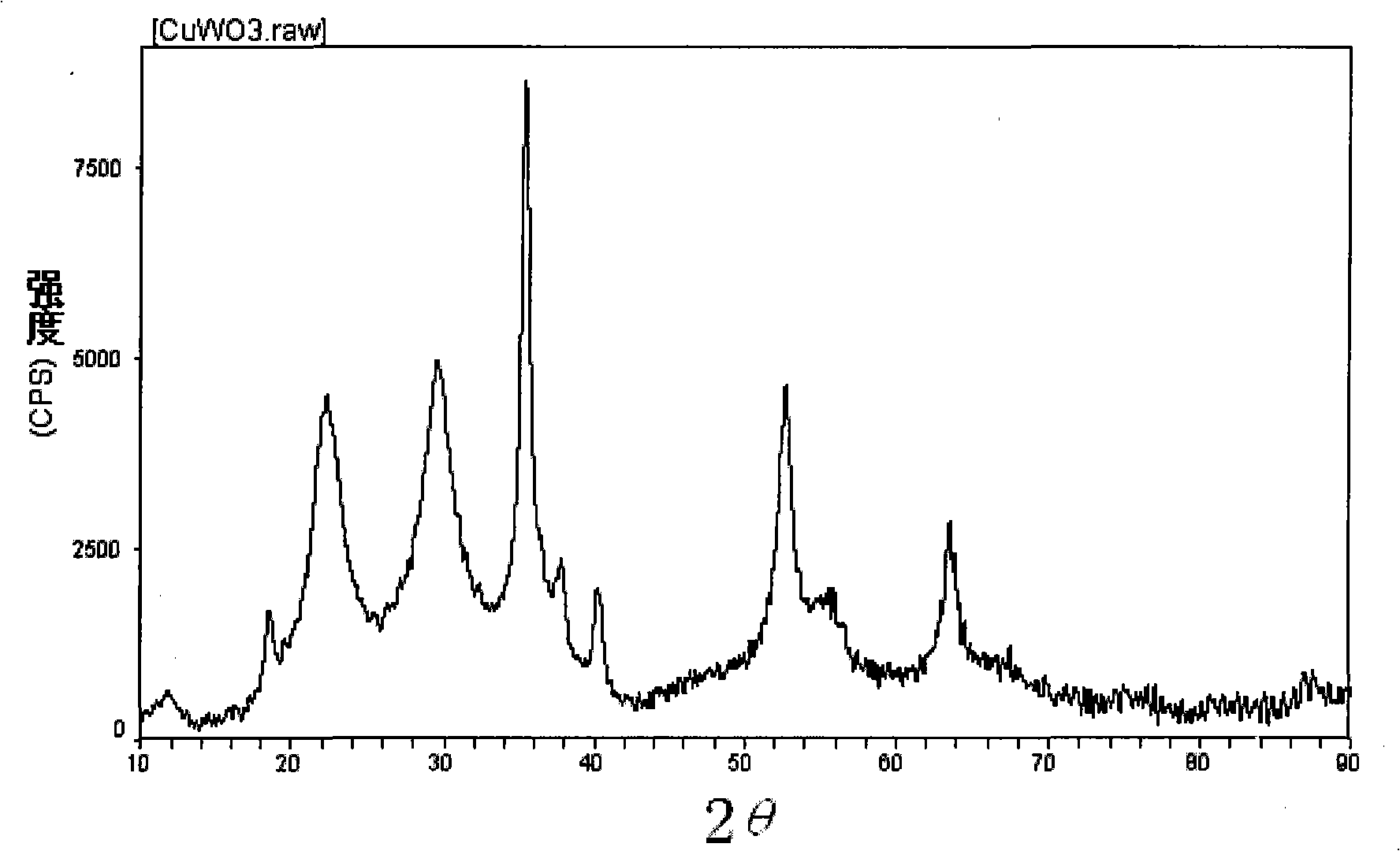

[0029] with WO 3 Content of 60g / l (NH 4 ) 2 WO 4 solution with ammoniacal Cu at pH 9 2+ Prepare the solution to obtain the mother liquor; heat the mother liquor to 80°C in a water bath, crystallize to a certain extent with the volatilization of the solvent, and evenly precipitate a precipitate in the mother liquor, filter and clean the obtained precipitate and dry it in a vacuum oven at 80°C to Quality is constant, obtains precursor powder, and X-diffraction analysis result shows (attached image 3 ) precursor is a mixture of copper tungstate and basic copper tungstate; the obtained precursor powder is passed through H at 450°C in a silicon rod reduction furnace 2 Reduce for 1 hour, then pass H at 700°C 2 After reduction for 1 hour, W-Cu composite powder was obtained. The SEM picture (attachment) of gained W-Cu composite powder Figure 4 ) shows that the W-Cu composite powder obtained by the reduction of the precursor powder is fine and uniform, and the particle shape i...

Embodiment 2

[0032] WO 3 Na content of 360g / l 2 WO 4 solution with CuCl at pH 3 2 After the solution is mixed, a precipitate is precipitated. After the obtained precipitate is filtered and cleaned, it is dried in a vacuum drying oven at 80°C until the quality is constant, and the precursor powder is obtained. The precursor powder is first passed through H at 450°C in a silicon rod reduction furnace. 2 Reduce for 1 hour, then pass H at 800°C 2 After reduction for 1 hour, W-Cu composite powder was obtained. The X-diffraction and SEM results of the obtained W-Cu composite powder show that the composite powder has achieved nanometer uniform mixing.

Embodiment 3

[0034] to (NH 4 ) 2 WO 4 、CuSO 4 As a raw material, the WO 3 Measured at 120g / l (NH 4 ) 2 WO 4 solution with Cu at pH 10 2+ The solution is prepared to obtain the mother liquor; the mother liquor is heated to 80°C in a water bath, and after 1 hour of heat preservation, a precipitate is uniformly precipitated in the mother liquor, and the obtained precipitate is filtered and cleaned, and dried in a vacuum drying oven at 80°C until the quality is constant to obtain a precursor powder, the precursor powder is passed through H at 450°C in the silicon rod reduction furnace 2 Reduce for 1 hour, then pass H at 700°C 2 After reduction for 1 hour, nanoscale W-Cu composite powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com