Method for preparing composite visual light catalytic material Ag3PO4 and g-C3N4

An ag3po4g-c3n4, catalytic material technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of low cost, simple and easy preparation method, and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

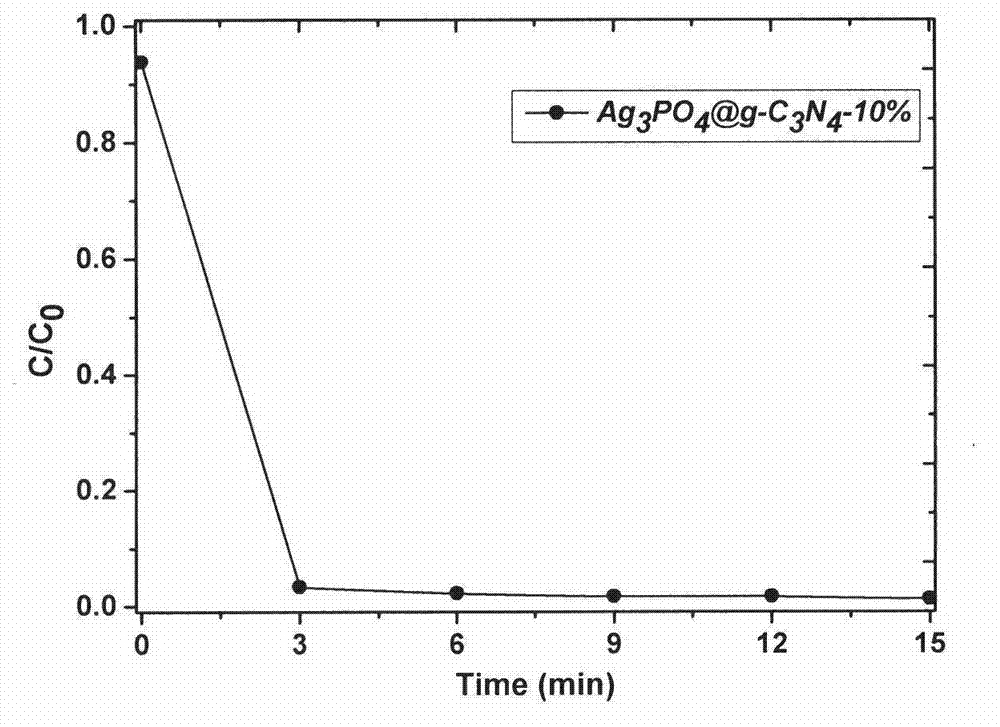

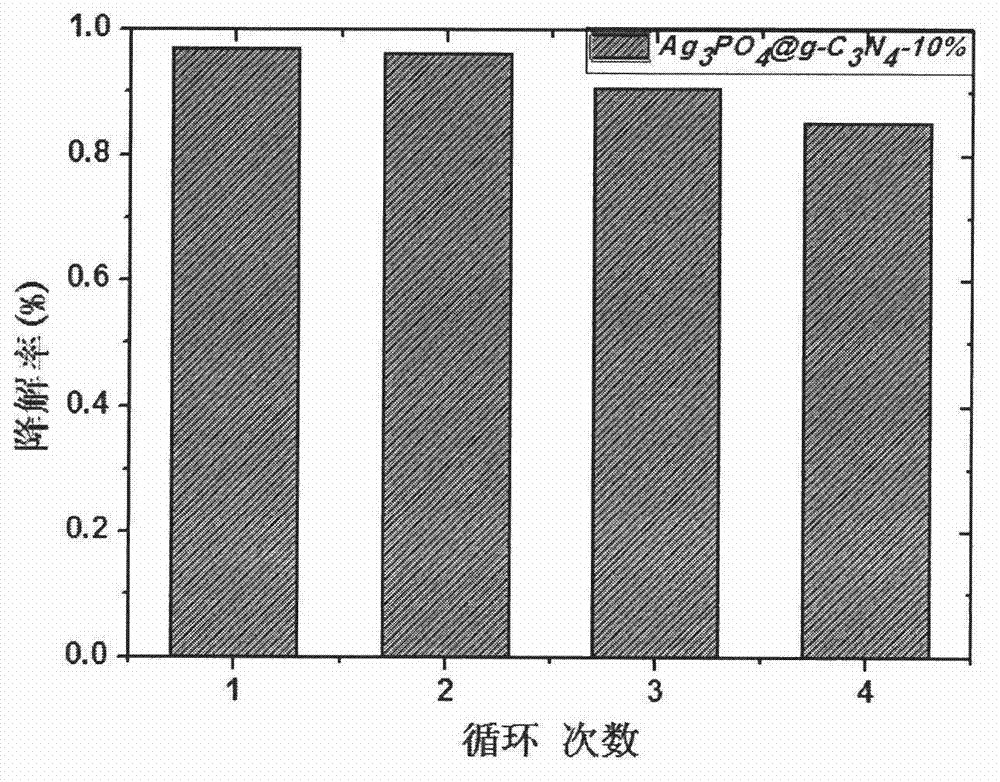

[0019] Weigh 0.1860g of g-C 3 N 4 powder, added into 30ml of deionized water, ultrasonicated for 30 minutes, then weighed 2.0385g (0.012mol) of silver nitrate and dissolved in the above dispersion, and kept stirring for 4 hours. Then measure Na at a concentration of 0.25M 3 PO 4 16ml of the solution was slowly added dropwise to the above mixed solution, and the reaction was continued for 24 hours, and the product was washed and dried to obtain the corresponding Ag 3 PO 4 g-C 3 N 4 -10% composite visible light catalytic material. Test the Ag 3 PO 4 g-C 3 N 4 -10% photocatalytic performance of visible photocatalytic materials for methyl orange, such as figure 1 shown.

Embodiment 2

[0021] Weigh 0.0881g of g-C 3 N 4 powder, added into 30ml of deionized water, ultrasonicated for 30 minutes, then weighed 2.0385g (0.012mol) of silver nitrate and dissolved in the above dispersion, and kept stirring for 4 hours. Then measure Na at a concentration of 0.25M 3 PO 4 16ml of the solution was slowly added dropwise to the above mixed solution, and the reaction was continued for 24 hours, and the product was washed and dried to obtain the corresponding Ag 3 PO 4 g-C 3 N 4 -5% composite visible light catalytic material.

Embodiment 3

[0023] Weigh 0.4186g of g-C 3 N 4 powder, added into 30ml of deionized water, ultrasonicated for 30 minutes, then weighed 2.0385g (0.012mol) of silver nitrate and dissolved in the above dispersion, and kept stirring for 4 hours. Then measure Na at a concentration of 0.25M 3 PO 4 16ml of the solution was slowly added dropwise to the above mixed solution, and the reaction was continued for 24 hours, and the product was washed and dried to obtain the corresponding Ag 3 PO 4 g-C3 N 4 -20% composite visible light catalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com