Method for treating high-COD (chemical oxygen demand) organic wastewater through microwave catalytic oxidation

A technology for microwave catalytic oxidation and organic wastewater, applied in oxidized water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc., can solve the problems of high operating costs and high prices, and achieve small footprint and low cost , Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

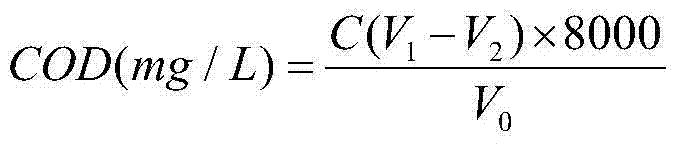

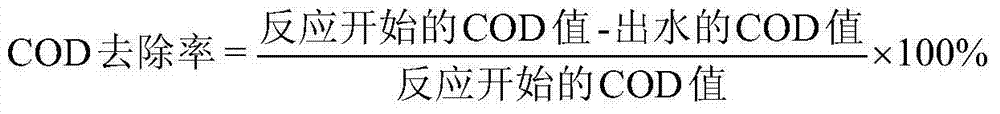

Embodiment 1

[0045] Using 4.5g of microwave catalyst supported by metal copper oxide on activated carbon, measure 150ml of organic wastewater with an initial COD value of 6752.13mg / L, and maintain a pH value between 8.0 and 9.0 at a microwave power of 400W. After a reaction time of 3 hours, take the above The COD value of the serum was detected by the national standard analysis method to be 305.62, and then the degradation rate was calculated to be 95.47%.

Embodiment 2

[0047] Using 4.5g of microwave catalyst supported by metal copper oxide on activated carbon, measure 150ml of organic wastewater with an initial COD value of 6988.92mg / L, and maintain a pH value between 8.0 and 9.0 at a microwave power of 400W. After a reaction time of 3 hours, take the above The COD value of the serum was detected by the national standard analysis method to be 269.07mg / L, and then the degradation rate was calculated to be 96.15%.

Embodiment 3

[0049] Using 4.5g of microwave catalyst supported by metal manganese oxide on activated carbon, measure 150ml of organic wastewater with an initial COD value of 9838.08mg / L, and maintain a pH value between 8.0 and 9.0 at a microwave power of 400W. After a reaction time of 4 hours, take the above The COD value of the serum was detected by the national standard analysis method to be 777.64mg / L, and then the degradation rate was calculated to be 92.09%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com