Recovery method of phosphate discharge liquid

A phosphoric acid and waste liquid technology, applied in chemical instruments and methods, ion exchange water/sewage treatment, water/sewage treatment, etc., can solve problems such as large energy consumption and large amount of vaporized water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

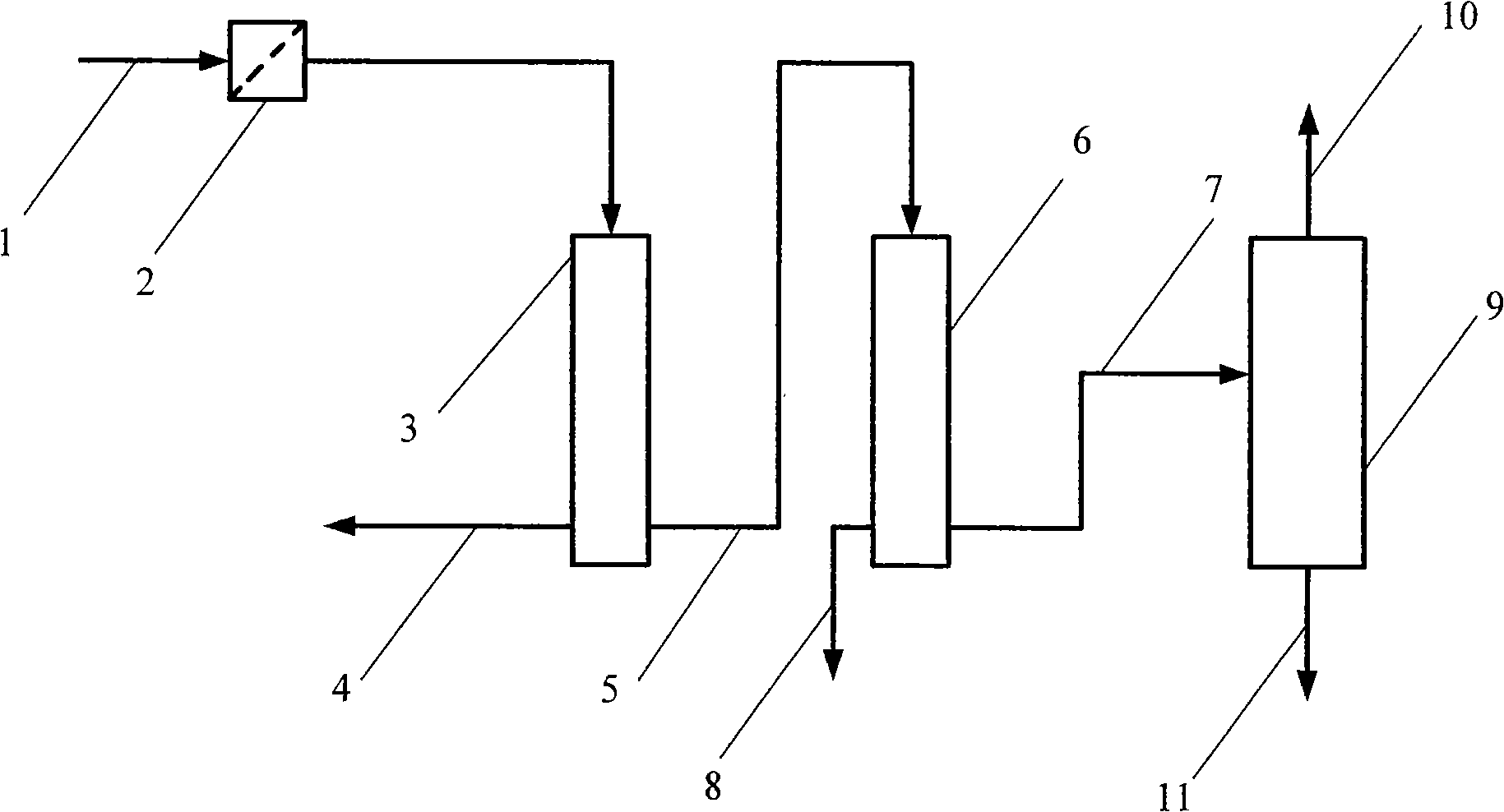

Method used

Image

Examples

Embodiment 1

[0030] Phosphoric acid waste liquid containing 0.5% phosphoric acid, temperature 20°C, flow rate 1.5m 3 / h. First pass through a 200-mesh stainless steel filter. Then enter the ion exchange tower A for ion exchange. The exchange tower A is filled with polystyrene-based strongly basic anion exchange resin, with a loading capacity of 1.8m 3 . The effluent enters the water treatment plant for treatment. After the exchange was carried out for 1 hour, a sodium hydroxide solution was introduced for regeneration treatment, and the regeneration solution entered the ion exchange tower B for ion exchange. Exchange column B is filled with polystyrene-based strong acidic cation exchange resin, with a loading capacity of 1.8m 3 After the exchange was carried out for 1 hour, the hydrochloric acid solution was passed through for regeneration. The ion exchange effluent enters the vacuum evaporator, the operating temperature is 30°C, and the vacuum degree is 2 kPa absolute pressure. The...

Embodiment 2

[0032] Phosphoric acid waste liquid containing 0.1% phosphoric acid, temperature 20°C, flow rate 2.5m 3 / h. First pass through a 200-mesh stainless steel filter. Then enter the ion exchange tower A for ion exchange. The exchange tower A is filled with polystyrene-based strong basic anion exchange resin, and the filling volume is 1.0m 3 . The effluent enters the water treatment plant for treatment. After the exchange was carried out for 1 hour, a sodium hydroxide solution was introduced for regeneration treatment, and the regeneration solution entered the ion exchange tower B for ion exchange. The exchange column B is filled with polystyrene series strong acidic cation exchange resin, and the filling volume is 1.0m 3 After the exchange was carried out for 1 hour, the hydrochloric acid solution was passed through for regeneration. The ion-exchange effluent enters the vacuum evaporator, the operating temperature is 110°C, and the vacuum degree is an absolute pressure of 10 ...

Embodiment 3

[0034] Phosphoric acid waste liquid containing 0.1% phosphoric acid, temperature 15°C, flow rate 2.5m 3 / h. First pass through a 100-mesh plate and frame filter. Then enter the ion exchange tower A for ion exchange. The exchange tower A is filled with polystyrene-based strong basic anion exchange resin, and the filling volume is 1.0m 3 . The effluent enters the water treatment plant for treatment. After the exchange was carried out for 1 hour, a sodium hydroxide solution was introduced for regeneration treatment, and the regeneration solution entered the ion exchange tower B for ion exchange. The exchange column B is filled with polystyrene series weakly acidic cation exchange resin, and the filling volume is 1.5m 3 After the exchange was carried out for 1 hour, the hydrochloric acid solution was passed through for regeneration. The ion exchange effluent enters the vacuum evaporator, the operating temperature is 40°C, and the vacuum degree is 5 kPa absolute pressure. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com