Particle appearance regulatory lithium iron phosphate preparation method

A particle, phosphate ion technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of rare morphology control and adjustment, and achieve the effects of low cost, uniform size distribution, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 0.3mol LiOH·H 2 O, 0.1mol FeSO 4 ·7H 2 O and 0.1mol H 3 PO 4 Mix, add 1000ml deionized water to dissolve, then add 30% sucrose, then transfer to 1000ml polytetrafluoroethylene reaction vessel, react at 175°C for 5 hours. After cooling, wash with deionized water and ethanol, centrifuge and dry. Finally, it was pyrolyzed at 500° C. for 1 hour in a sealed tube furnace protected by nitrogen to obtain the lithium iron phosphate granular product.

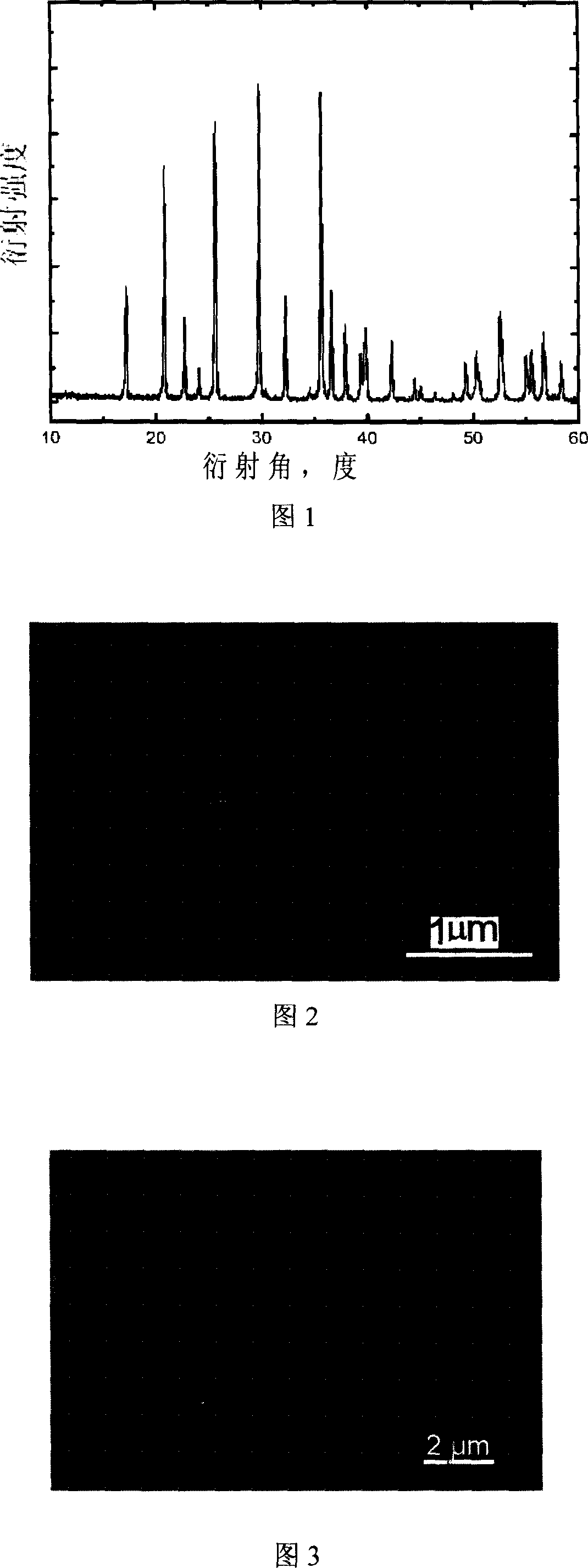

[0026] The obtained lithium iron phosphate product has an olivine structure, and the X-ray diffraction pattern of the product is obtained by using Cu target Kα radiation, λ=0.15406nm, as shown in FIG. 1 . Through a field emission scanning electron microscope, it can be seen that the lithium iron phosphate particles are rod-shaped, about 1 μm in length, and 0.2-0.4 μm in width and height, as shown in FIG. 2 . The charge and discharge curve of this product is shown in Figure 8, the voltage range is 2.0-4.1V, the temperature is ...

Embodiment 2

[0028]0.005mol FePO 4 and 0.01mol LiOH·H 2 O mixed, add 200mL water / ethanol (1:1 / V:V) mixed solvent, then add 50% citric acid, then transfer to a polytetrafluoroethylene reaction vessel, react at 200°C for 5 hours. After cooling, it was washed with deionized water and ethanol, centrifuged, dried, and calcined at 600°C for 5 hours in an argon-protected sealed tube furnace to obtain a lithium iron phosphate product. The product is uniform and spindle-shaped, with a width of about 0.3-0.6 μm and a length of 3-5 μm (see Figure 3).

Embodiment 3

[0030] 0.12mol LiOH·H 2 O, 0.04mol (NH 4 ) 2 Fe(SO 4 ) 2 12H 2 O and 0.04mol(NH 4 ) 2 HPO 4 Mix, add 400ml of water / ethylene glycol (5:1 / V:V) mixed solution, add 4% PAA, then transfer to a polytetrafluoroethylene reaction vessel, and react at 220° C. for 2 hours. After cooling, wash with deionized water and ethanol, centrifuge and dry to obtain lithium iron phosphate particle product. The products are short rods, about 0.8 μm in length and 0.2 μm in width, arranged in an array (see Figure 4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com