Preparation method of nano-diamond electrolyte and nano-diamond solid electrolyte interface

A nano-diamond and solid electrolyte technology, which is applied in the manufacture of electrolyte batteries, electrode carriers/collectors, non-aqueous electrolyte batteries, etc., can solve problems such as unsuitable for large-scale industrial mass production, harsh conditions in the preparation process, and complex additive structures. To achieve the effect of inhibiting volume expansion, easy to implement, and easy to scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of nano-diamond electrolyte

[0037] Take the concentrated hydrochloric acid and the concentrated sulfuric acid solution of 5ml respectively, configure the mixed acid solution that the volume ratio is 1:1; The concentrated hydrochloric acid is the hydrochloric acid solution that commercially available concentration is 36wt%~38wt%; The concentrated sulfuric acid is the concentration 98wt% sulfuric acid solution;

[0038] Add 0.2g (particle size: 5-10nm) of nano-diamond particles into the above mixed acid solution, and heat at 200°C for 30-40min to remove metal impurities on the surface of the diamond particles;

[0039] Take 0.1 g of acid-treated nano-diamond particles, and treat them under ultraviolet (BZS250GF-TC) irradiation for 15 s (15-20 s are acceptable) to obtain oxygen-terminated nano-diamond particles;

[0040] Commercial 1mol / L LiPF 6 (EC:DMC=1:1) The electrolyte is recorded as sample 1, take 0.024g of oxygen-terminated nano-dia...

Embodiment 2

[0042] Embodiment 2: the making of lithium ion battery

[0043] The lithium-ion battery negative electrode is composed of 80wt% commercial graphite (active material), 10wt% binder (polyvinylidene fluoride, PVDF) and 10wt% conductive aid carbon black.

[0044] The three were mixed and ground for 0.5 h, then put into a container, and a certain amount of 1-methyl-2-pyrrolidone (NMP, solvent) was added into the container, and then placed on a magnetic stirrer and stirred at a constant speed for 6 h, until the mixture became a viscous fluid.

[0045] Copper foil is used as a current collector, and the above-mentioned mixed viscous material is coated on the copper foil, and the coating density must be uniform.

[0046] The temperature of the vacuum drying oven was set at 120° C., and the above-mentioned copper foil smear was taken and placed in the drying oven. After timing for 12 hours, it was taken out for use.

[0047] The prepared copper foil smear is cut into several electrode...

Embodiment 3

[0051] Embodiment 3: the test of lithium-ion battery and the formation of nano-diamond solid electrolyte interface

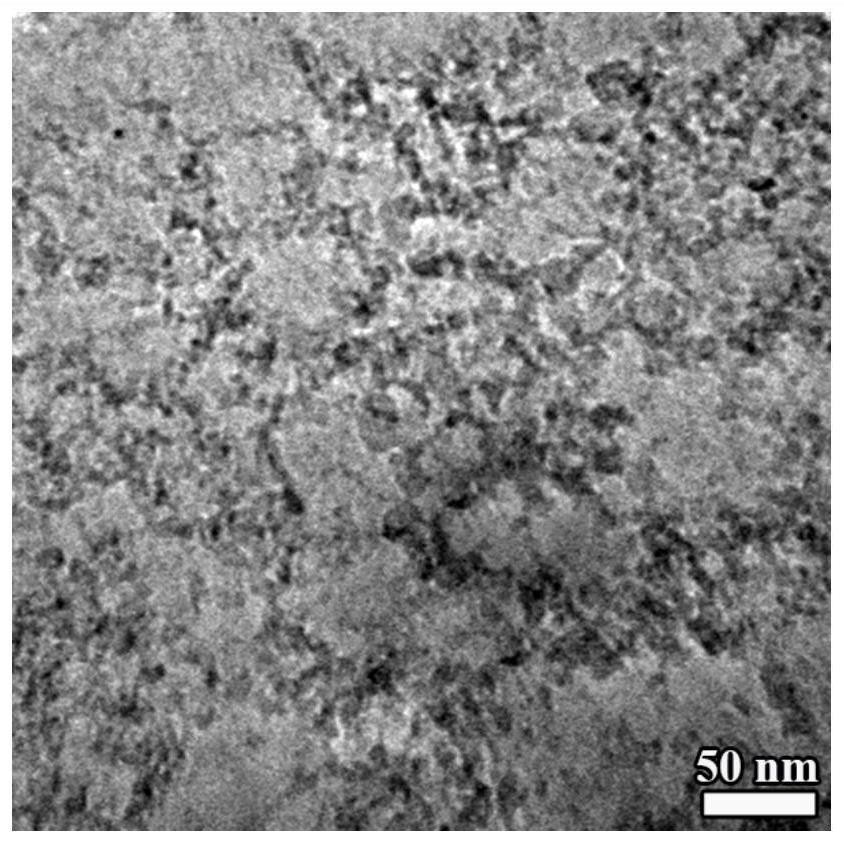

[0052] The electrochemical performance of batteries S1 and S2 was tested in the blue electric test system. At 25°C, discharge to 0.01V at a certain rate; after discharge, let the battery stand for 3 minutes; then charge to 3V at a certain rate, after charging, discharge the battery at the same constant rate for 3 minutes to 0.01V; after discharging the battery, let it stand for 3 minutes, and then charge it under the same conditions. After the test was completed, the active substances in S1 and S2 were taken out and recorded as sample 3 and sample 4, and were characterized by a transmission electron microscope (JEM-2100F, JEOL).

[0053] Testing and Characterization

[0054] 1) Charge and discharge performance test

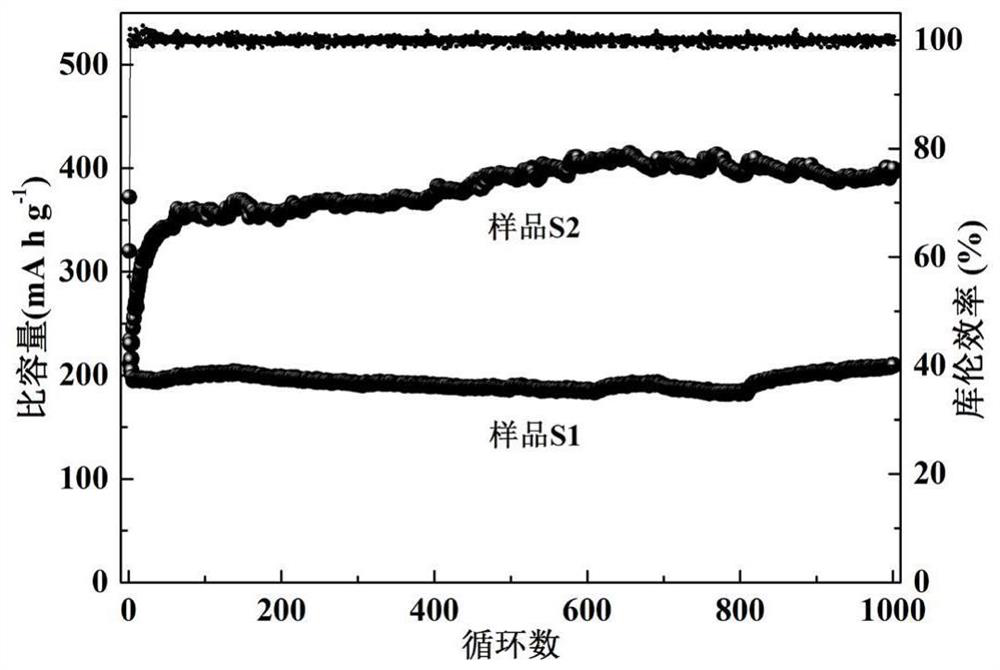

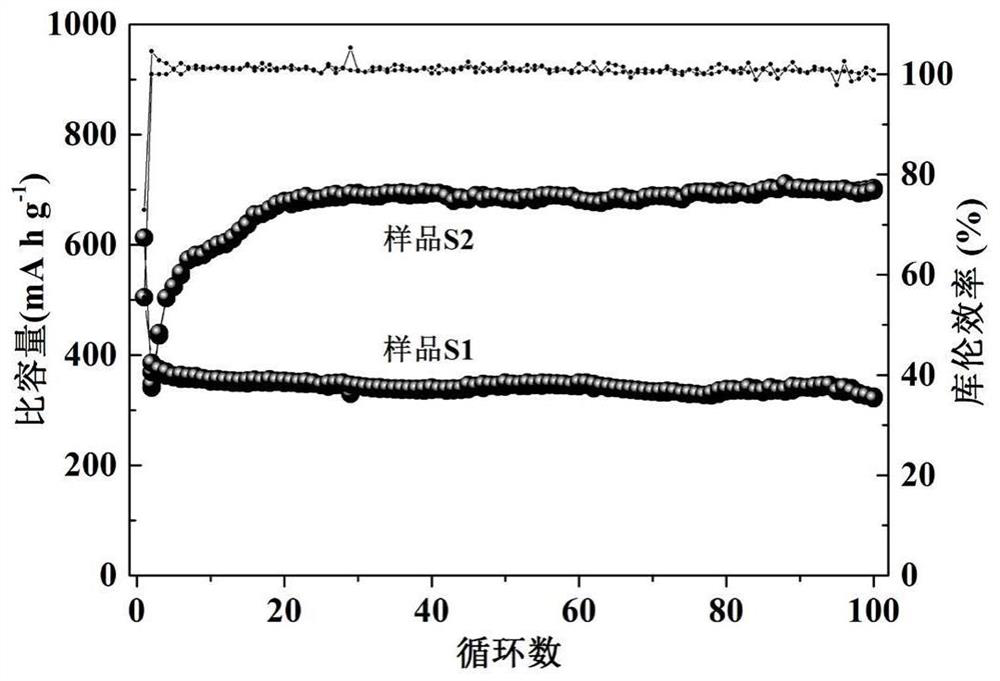

[0055] The electrochemical performance test results at 5C rate are as follows: figure 2 It can be seen from the figure that the initial discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com