Friction Stir Welding Process

A friction stir and welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as poor mechanical properties of welds, inability to meet actual production needs, and low welding coefficients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

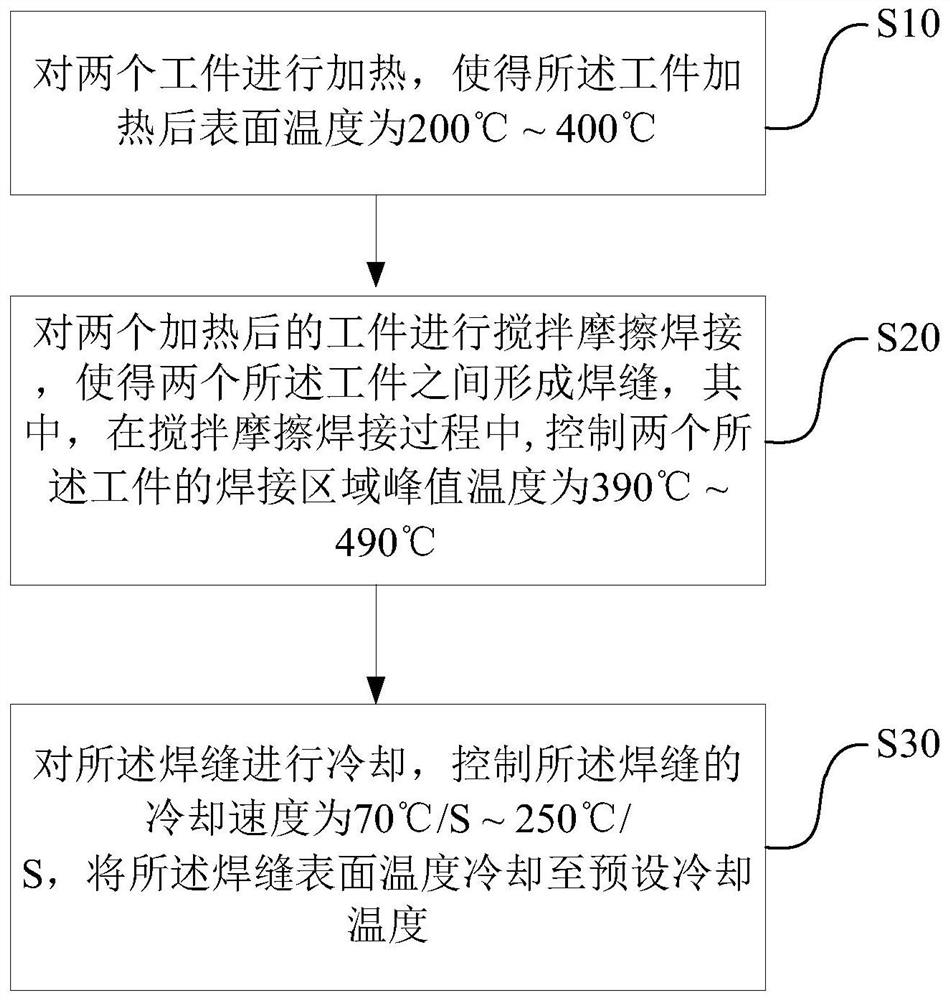

Method used

Image

Examples

Embodiment 1

[0057] The workpiece processed in this embodiment is 7055-T6 ultra-high-strength aluminum alloy with a width of 200 mm, a thickness of 5 mm, and a length of 1000 mm. The specific friction stir welding process steps are as follows:

[0058] (1) Before friction stir welding, the aluminum alloy is preheated by natural gas, wherein the flow rate of natural gas is 1m 3 / h, the height of the natural gas nozzle from the surface of the aluminum alloy is 40mm; at this time, the heating rate of the aluminum alloy is 30°C / s, and the surface temperature of the aluminum alloy reaches 250°C after heating;

[0059] (2) The two aluminum alloys are then welded by a friction stir welding device. The rotation speed of the stirring head is 800rpm, the moving speed of the stirring head is 60mm / min, and the shoulder is pressed into the surface of the aluminum alloy by 0.5mm. At this time, the peak value of the welding area is The temperature is 415°C;

[0060] (3) Rapid cooling of the weld seam b...

Embodiment 2

[0063] The workpiece processed in this embodiment is 7055-T6 ultra-high-strength aluminum alloy with a width of 200 mm, a thickness of 5 mm, and a length of 1000 mm. The specific friction stir welding process steps are as follows:

[0064] (1) Before friction stir welding, the aluminum alloy is preheated by natural gas, wherein the flow rate of natural gas is 2.5m 3 / h, the height of the natural gas nozzle from the surface of the aluminum alloy is 40mm; at this time, the heating rate of the aluminum alloy is 40°C / s, and the surface temperature of the aluminum alloy reaches 300°C after heating;

[0065] (2) The two aluminum alloys are then welded by a friction stir welding device. The rotation speed of the stirring head is 800rpm, the moving speed of the stirring head is 60mm / min, and the shoulder is pressed into the surface of the aluminum alloy by 0.5mm. At this time, the peak value of the welding area is The temperature is 465°C;

[0066] (3) Rapid cooling of the weld seam...

Embodiment 3

[0069] The workpiece processed in this embodiment is 7055-T6 ultra-high-strength aluminum alloy with a width of 200 mm, a thickness of 5 mm, and a length of 1000 mm. The specific friction stir welding process steps are as follows:

[0070] (1) Before friction stir welding, the aluminum alloy is preheated by natural gas, wherein the flow rate of natural gas is 4m 3 / h, the height of the natural gas nozzle from the surface of the aluminum alloy is 40mm; at this time, the heating rate of the aluminum alloy is 45°C / s, and the surface temperature of the aluminum alloy reaches 350°C after heating;

[0071] (2) The two aluminum alloys are then welded by a friction stir welding device. The rotation speed of the stirring head is 800rpm, the moving speed of the stirring head is 60mm / min, and the shoulder is pressed into the surface of the aluminum alloy by 0.5mm. At this time, the peak value of the welding area is The temperature is 465°C;

[0072] (3) Rapid cooling of the weld seam b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com