Hydro-thermal synthesis method for shape-controllable nano iron oxide

A nano-iron oxide, hydrothermal synthesis technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problem that nanoparticles cannot meet the size controllability and other problems, achieve novel process steps, realize size and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for hydrothermal synthesis of nano-iron oxide with controllable morphology, comprising the steps of:

[0028] (1) Weigh 7.26g (0.03mol) of ferric nitrate (12.12g of ferric nitrate nonahydrate), add it to 580ml of deionized water, stir until completely dissolved, and obtain a precursor solution; the mass of deionized water is 80 times the mass of ferric nitrate ;

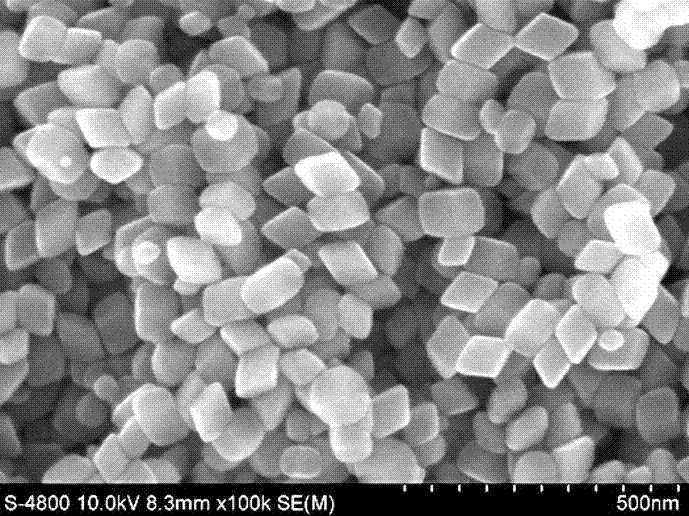

[0029] (2) Put the precursor solution in the reaction kettle, heat it to 170°C, and keep it warm for 2 hours; cool it down to room temperature, add deionized water and alcohol to the obtained product, oscillate fully, and centrifuge. The centrifugal speed in the centrifugation step is 3000rad / min, centrifuge twice, each time for 3min, remove the supernatant, move the contents to an electric vacuum drying oven, and dry until constant weight to obtain nanometer iron oxide. The nano-iron oxide has a triclinic tetragonal structure, and the crystal side length is about 40-60 nm. The SEM image is shown in...

Embodiment 2

[0031] A method for hydrothermal synthesis of nano-iron oxide with controllable morphology, comprising the steps of:

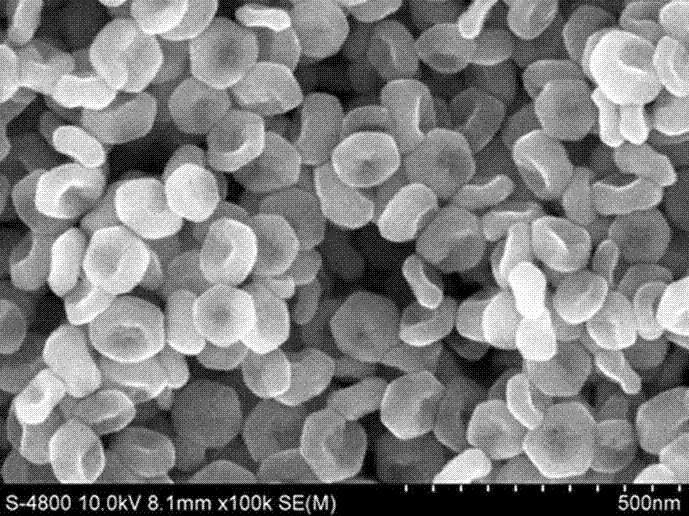

[0032] (1) Weigh 0.006g (0.00005mol) sodium dihydrogen phosphate, 0.092g (0.00053mol) potassium sulfate and 0.324g (0.002mol) ferric chloride (0.54g ferric chloride hexahydrate), mix and add 100 ml deionized In water, stir until fully dissolved to obtain a precursor solution; in the precursor solution, the mol ratio of phosphate ion and ferric ion is 0.25:10, and the mol ratio of strong acid and strong alkali salt to ferric ion is 2.65: 10. The quality of deionized water is 250 times the total mass of sodium dihydrogen phosphate, sodium sulfate and ferric chloride;

[0033] (2) Put the precursor solution in the reaction kettle, heat it to 200°C, and keep it warm for 2 hours; cool it to room temperature, add deionized water and alcohol to the obtained product, oscillate fully, and centrifuge. The centrifugal speed in the centrifugation step is 5000rad / min, ce...

Embodiment 3

[0035] A method for hydrothermal synthesis of nanometer iron oxide with controllable morphology, comprising the steps of:

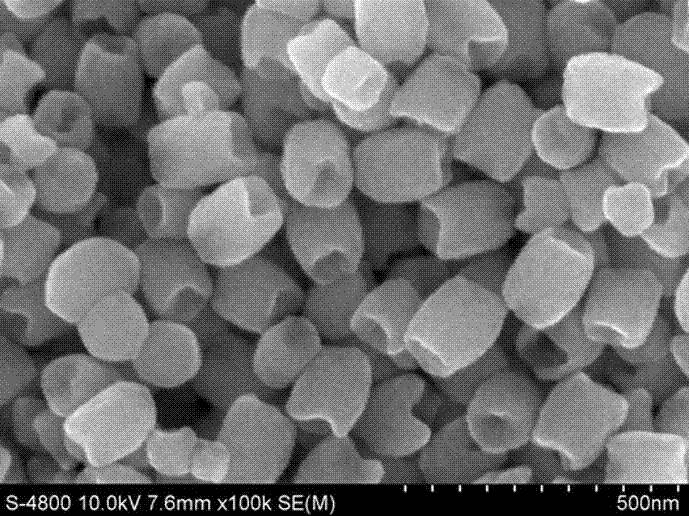

[0036](1) Weigh 0.018g (0.00015mol) sodium dihydrogen phosphate, 0.092g (0.00053mol)

[0037] Potassium sulfate and 0.324g (0.002mol) ferric chloride (0.54g ferric chloride hexahydrate), mixed into 100ml deionized water, stirred until completely dissolved, to obtain a precursor solution; in the precursor solution, the phosphate ion and The molar ratio of ferric ions is 0.75:10, the molar ratio of strong acid and strong alkali salts to ferric ions is 2.65:10, and the quality of deionized water is 240% of the total mass of sodium dihydrogen phosphate, sodium sulfate and ferric chloride. times;

[0038] (2) Put the precursor solution in the reaction kettle, heat to 180°C, keep it warm for 2 hours; cool to

[0039] At room temperature, add the obtained product to deionized water and alcohol, fully oscillate, and centrifuge. In the centrifugation step, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com