Method for preparing tungsten trioxide nano material

A nanomaterial, tungsten trioxide technology, applied in nanostructure manufacturing, tungsten oxide/tungsten hydroxide, nanotechnology, etc., can solve the problems of difficult product morphology and size modulation, product morphology and adverse effects on properties, etc. The effect of avoiding adverse effects, easy industrial production, and easy process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

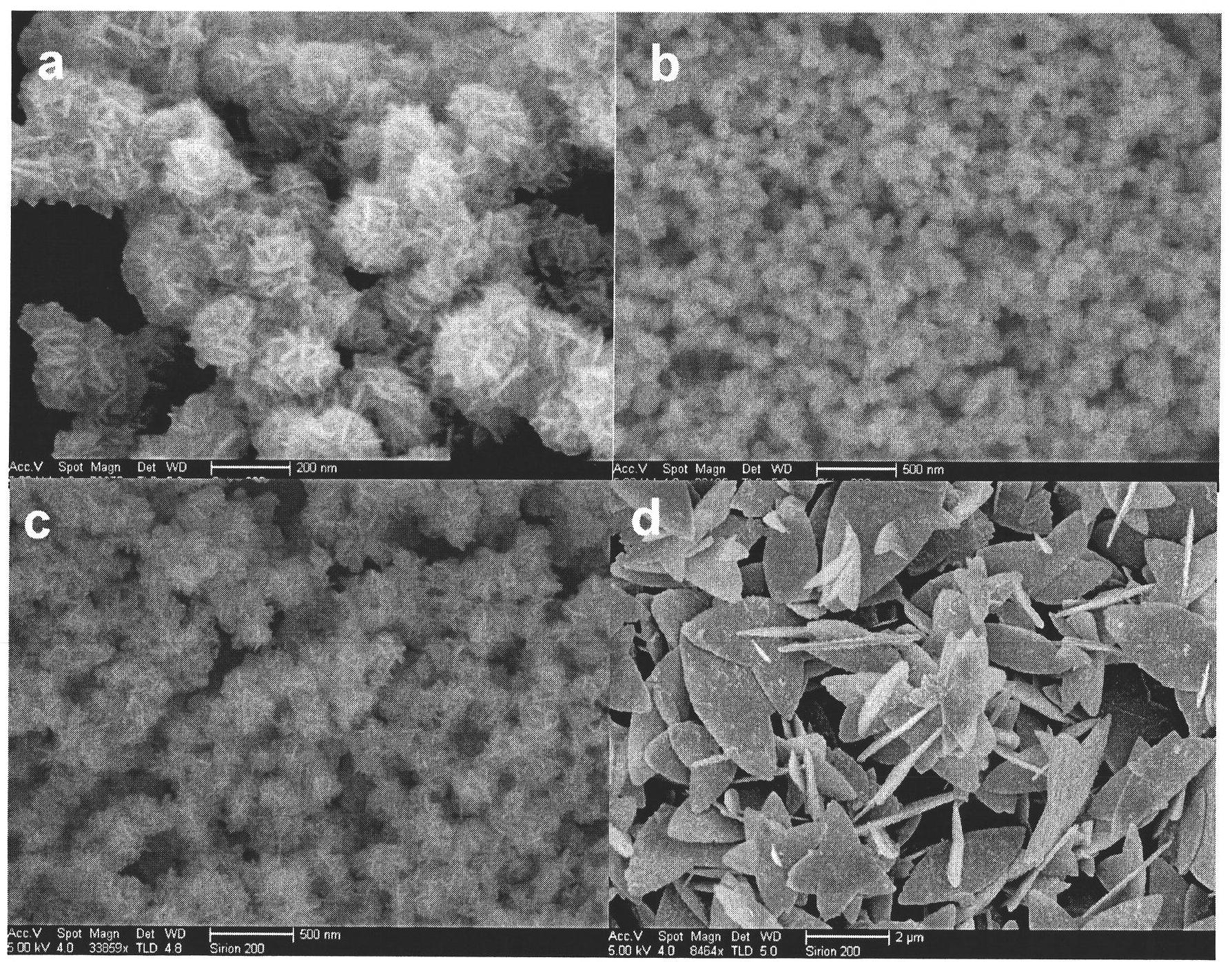

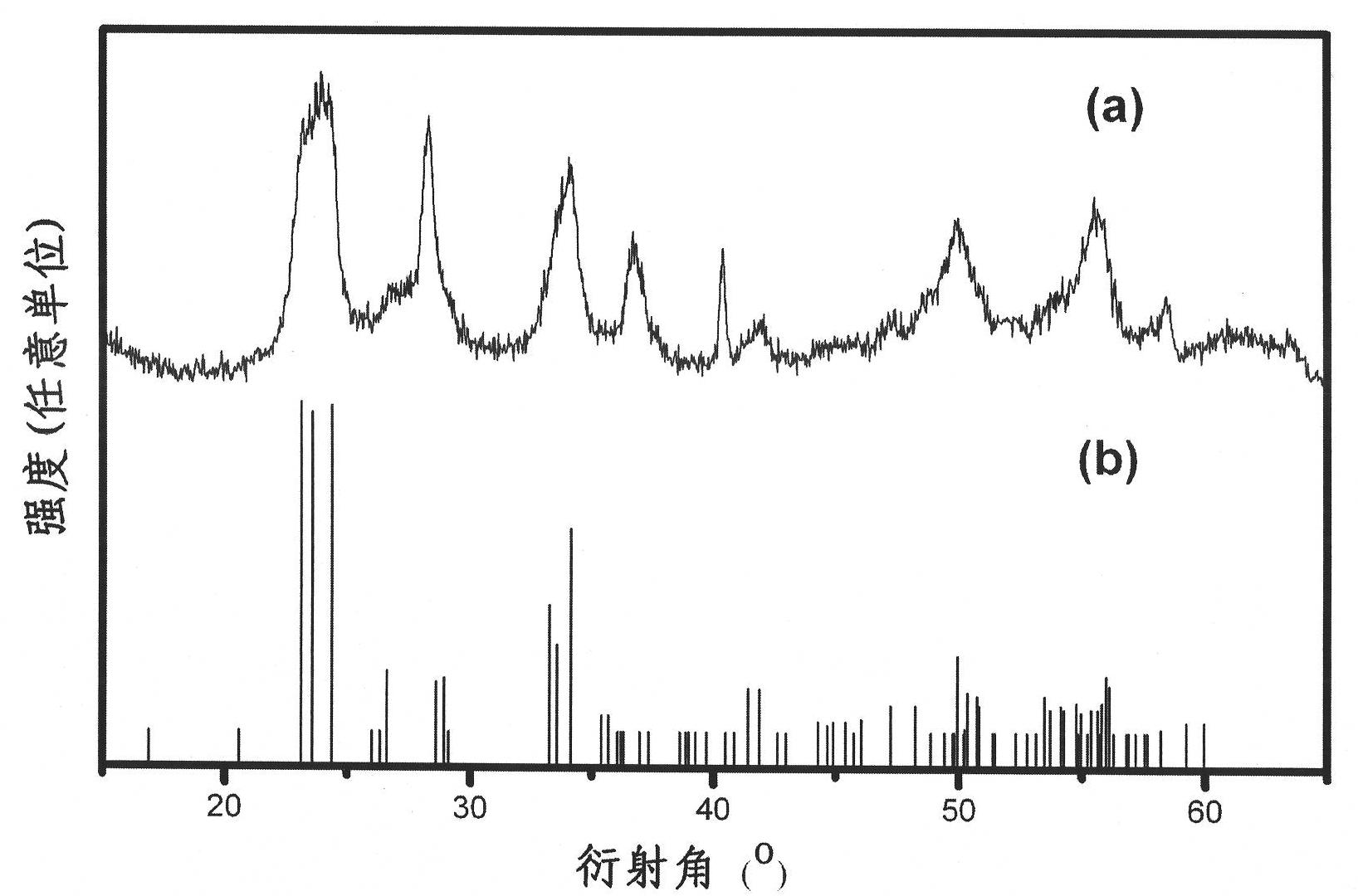

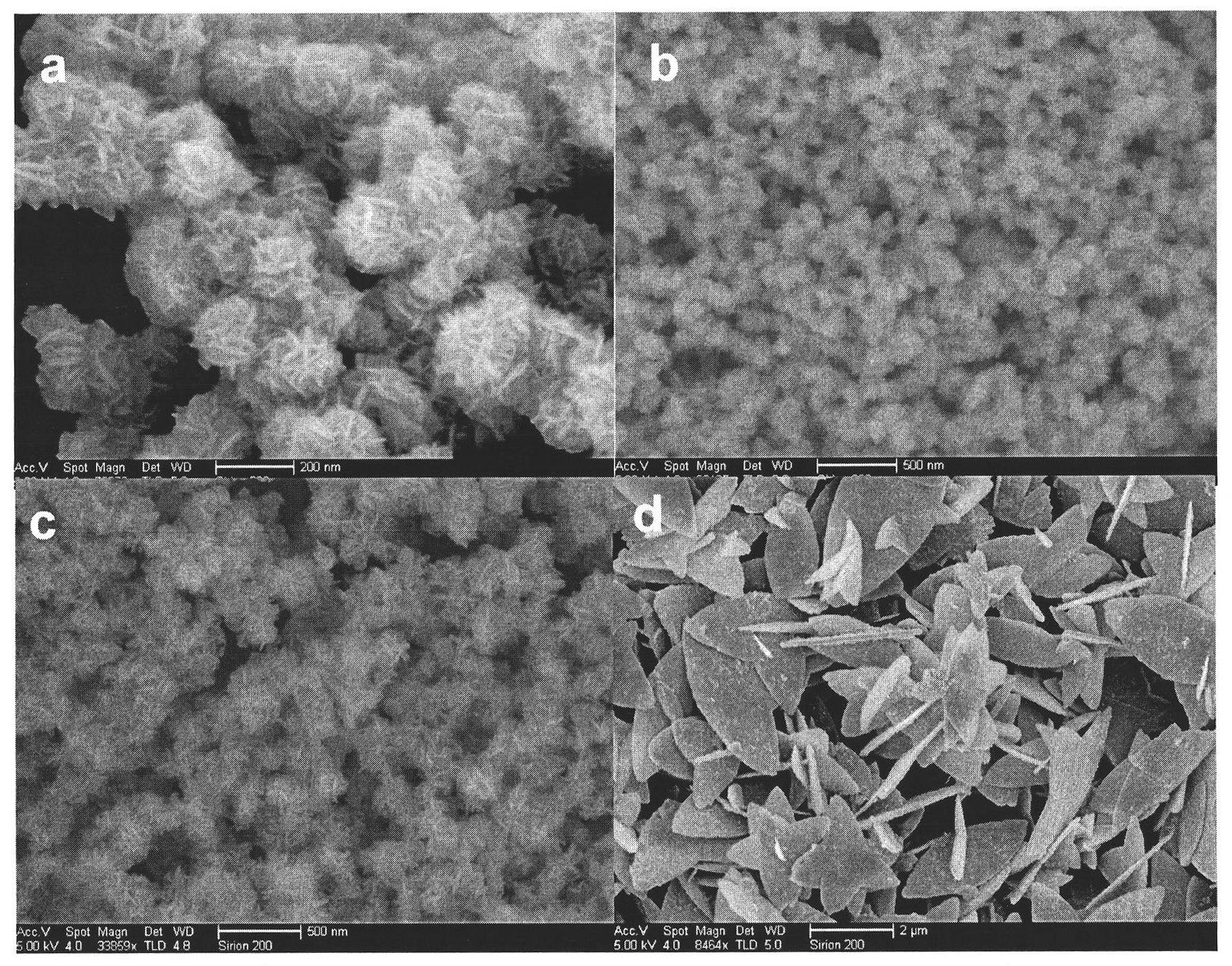

Image

Examples

Embodiment 1

[0019] The concrete steps of preparation are:

[0020] Step 1, first place the metal tungsten sheet in deionized water under stirring; wherein, the purity of the metal tungsten sheet is 99.9%. Then use a laser with a wavelength of 1064nm, a pulse width of 5ns, a repetition rate of 20Hz, and a single pulse energy of 50mJ to irradiate the metal tungsten sheet for 12min; wherein, the laser spot diameter is 1.5mm, and the laser is a Nd:YAG solid-state laser to obtain tungstic acid colloidal solution. Then, the tungstic acid colloidal solution is subjected to aging treatment for 24 hours; or acid is added to the tungstic acid colloidal solution to adjust its pH value to -0.6, wherein the acid is sulfuric acid; a yellow precipitate is obtained.

[0021] Alternatively, first place the metal tungsten sheet in an acid solution with a pH value of -0.6 under stirring; wherein, the purity of the metal tungsten sheet is 99.9%, and the acid is sulfuric acid. Then use a laser with a wavele...

Embodiment 2

[0024] The concrete steps of preparation are:

[0025] Step 1, first place the metal tungsten sheet in deionized water under stirring; wherein, the purity of the metal tungsten sheet is 99.99%. Then use a laser with a wavelength of 1064nm, a pulse width of 8ns, a repetition rate of 15Hz, and a single pulse energy of 65mJ to irradiate the metal tungsten sheet for 11.5min; wherein, the spot diameter of the laser is 1.8mm, and the laser is a Nd:YAG solid-state laser to obtain tungsten acid colloid solution. Next, aging treatment is performed on the tungstic acid colloidal solution for 25 hours; or adding acid to the tungstic acid colloidal solution to adjust its pH value to 0, wherein the acid is sulfuric acid; a yellow precipitate is obtained.

[0026] Alternatively, first place the metal tungsten sheet in an acid solution with a pH value of 0 under stirring; wherein, the purity of the metal tungsten sheet is 99.99%, and the acid is sulfuric acid. Then use a laser with a wavel...

Embodiment 3

[0029] The concrete steps of preparation are:

[0030] Step 1, first place the metal tungsten sheet in deionized water under stirring; wherein, the purity of the metal tungsten sheet is 99.9%. Then use a laser with a wavelength of 1064nm, a pulse width of 10ns, a repetition rate of 10Hz, and a single pulse energy of 80mJ to irradiate the metal tungsten sheet for 11min; wherein, the laser spot diameter is 2mm, and the laser is a Nd:YAG solid-state laser to obtain tungstic acid colloid solution. Then, the tungstic acid colloidal solution is subjected to aging treatment for 26 hours; or acid is added to the tungstic acid colloidal solution to adjust its pH value to 1, wherein the acid is sulfuric acid; a yellow precipitate is obtained.

[0031] Alternatively, first place the metal tungsten sheet in an acid solution with a pH value of 1 under stirring; wherein, the purity of the metal tungsten sheet is 99.9-99.99%, and the acid is sulfuric acid. Then use a laser with a wavelengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com