Method for mfg nano copper powder

A copper powder and nano-level technology, applied in the field of metal powder preparation, can solve the problems such as unreported production methods of ultra-fine nano-copper powder, and achieve the effects of saving precipitation time, rapidly precipitation of nanoparticles, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

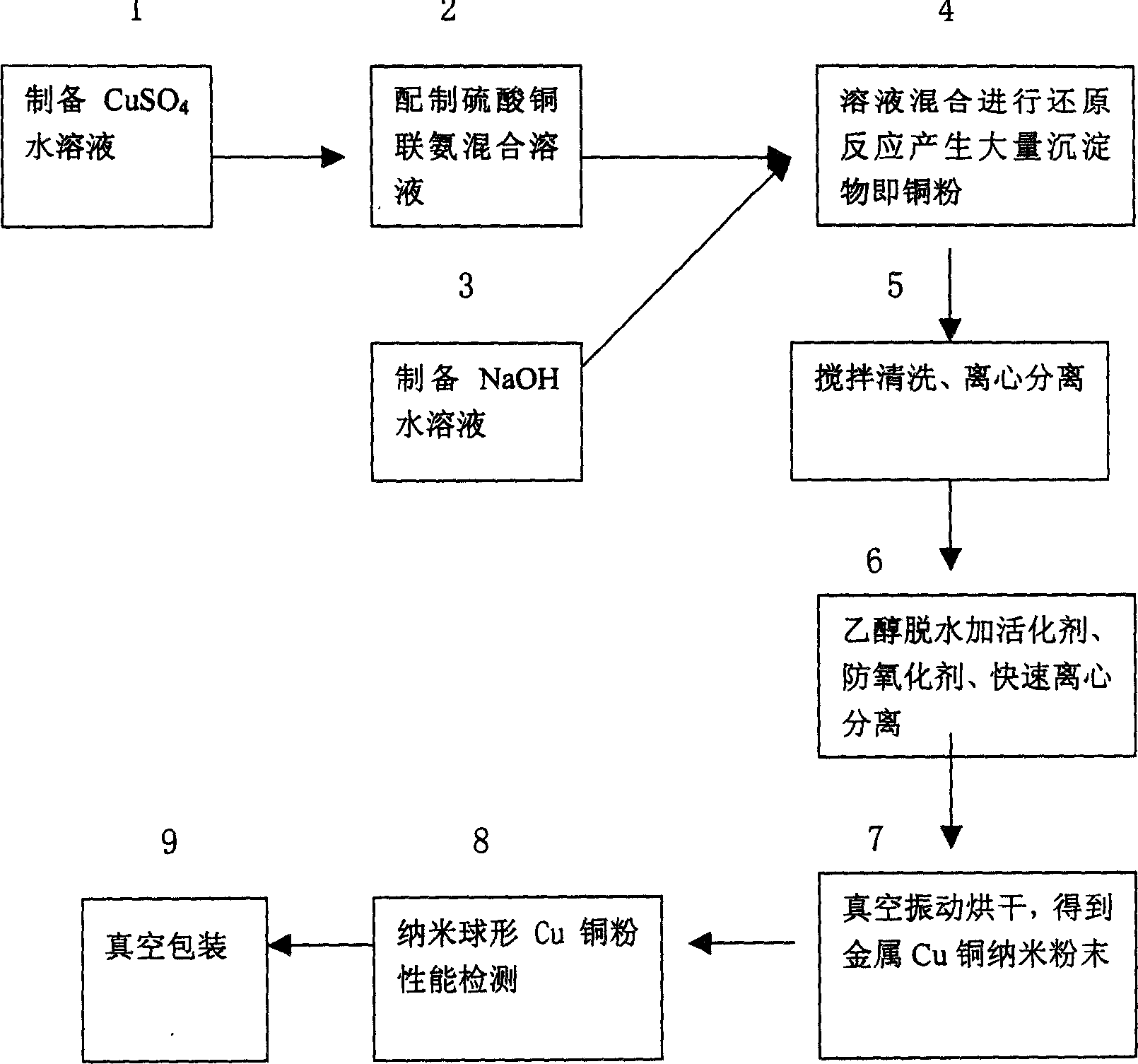

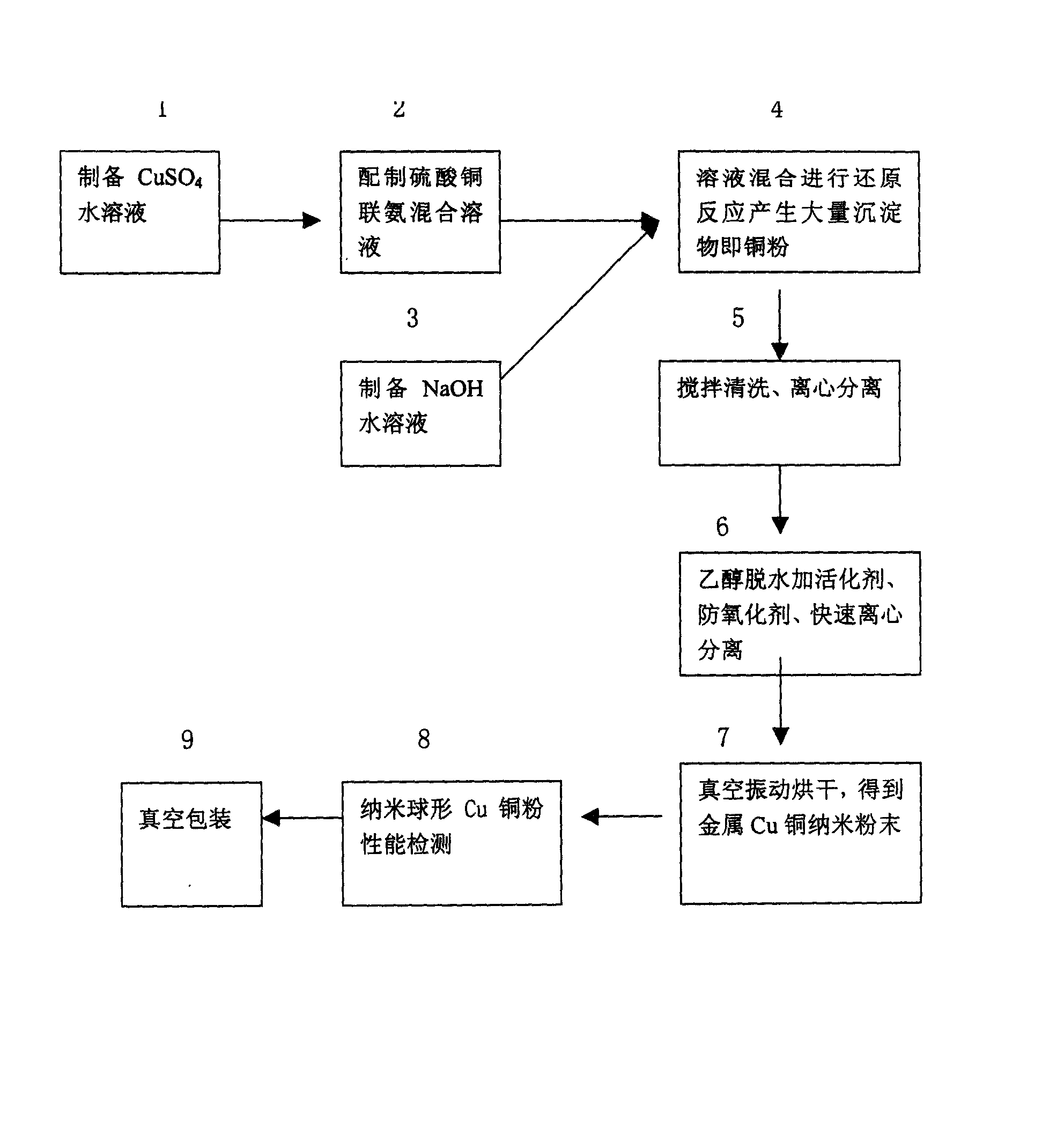

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: When preparing 1 kg of nano Cu powder, it should be completed according to the following steps.

[0033] 1. Weigh 2.6kg CuSO 4 ·5H 2 O copper sulfate powder, CuSO 4 ·5H 2 O copper sulfate as CuSO 4 ·5H 2 O:H 2 Add O=1:1.5 mass ratio into water, heat to 40-50°C to fully dissolve, and filter impurities to prepare CuSO 4 aqueous solution;

[0034] 2. Preparation of NaOH caustic soda aqueous solution

[0035] Add 100g of NaOH caustic soda solid into 1000g of water and stir, fully dissolve and filter impurities to make NaOH aqueous solution for later use;

[0036] 3. Preparation of copper sulfate hydrazine mixed solution

[0037]According to the mass ratio of copper sulfate: hydrazine=1:0.5, 1.3kg of hydrazine solution was weighed, and the CuSO 4 The aqueous solution was slowly poured into N 2 h 4 ·H 2 Mix and stir in O hydrazine solution to prepare copper sulfate hydrazine mixed solution

[0038] 4. Slowly pour the NaOH aqueous solution into the ...

Embodiment 2

[0046] Embodiment 2: When preparing 500g of nano Cu powder, it should be completed according to the following steps.

[0047] 1. Weigh 1.3kg CuSO 4 ·5H 2 O copper sulfate powder, CuSO 4 ·5H 2 O copper sulfate as CuSO 4 ·5H 2 O:H 2 Add O=1:1.5 ratio to water, heat to 50°C, make it fully dissolved and filter to remove impurities, and prepare CuSO 4 aqueous solution;

[0048] 2. Preparation of NaOH caustic soda aqueous solution

[0049] Add 50g NaOH caustic soda solid into 500g water and stir, dissolve and filter impurities to make NaOH aqueous solution for subsequent use;

[0050] 3. Preparation of copper sulfate hydrazine mixed solution

[0051] According to the mass ratio of copper sulfate: hydrazine=1:0.5, 650g of hydrazine was weighed, and the CuSO 4 The aqueous solution was slowly poured into N 2 h 4 ·H 2 Mix and stir in O hydrazine solution; prepare copper sulfate hydrazine mixed solution

[0052] 4. It is basically the same as 4 in Example 1, except that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com