Uniformly coordinating precipitation method for preparing nano zinc oxide

A technology of coordinated uniform precipitation and nano-zinc oxide, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, oxygen/ozone/oxide/hydroxide, etc., can solve the problem of impure products and difficulty in obtaining particle size It can control the product and other problems to achieve the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, the steps of preparing nano-zinc oxide by coordination uniform precipitation method are described as follows:

[0015] Using zinc oxide as raw material, ammonia water NH 3 ·H 2 O and ammonium bicarbonate are complexing agents and simultaneously used as precipitating agents to prepare zinc ammonia complex solution, and then add ammonium sulfide or sodium sulfide solution with a concentration of 0.1-1mol / l until white precipitation just appears, and obtain refined tetracarbonate after filtration Solution of ammoniated zinc(II) complex.

[0016]

[0017] (M 2+ for heavy metal ions)

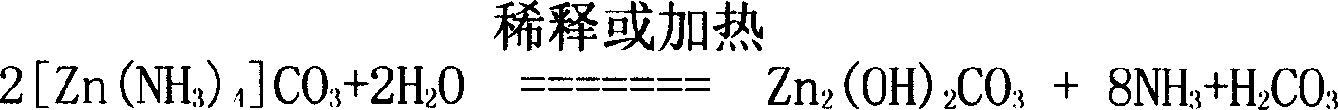

[0018] The refined complex solution is heated or diluted with water, and as the concentration of ammonia decreases, zinc ions are uniformly precipitated in the entire solution, and immediately react with carbonate groups evenly distributed in the solution system to uniformly generate basic zinc carbonate precipitation:

[0019]

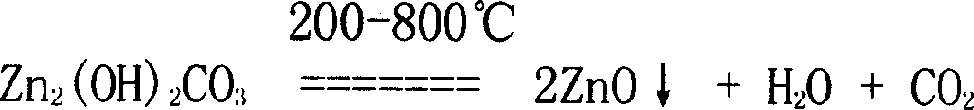

[0020] Heat and decompose...

Embodiment 2

[0037] Example 2, at room temperature, 1 molar amount of solid zinc oxide and 1 to 2 molar amounts of solid sodium bicarbonate or sodium carbonate and 3-5 molar amounts of ammonia water NH 3 ·H 2 O mixed, react at room temperature until the solid zinc oxide is completely dissolved; while stirring, add dropwise a solution of ammonium sulfide or sodium sulfide with a concentration of 0.1-1mol / l until a white precipitate just appears, and obtain refined tetraammonium carbonate after filtration Zinc (II) complex solution; then add a total weight of 0.3-8% surfactant to the above solution, slowly add distilled water to the complex solution under stirring until it just appears turbid, and let it Precipitate for 1-4 hours, filter to obtain basic zinc carbonate precipitate, wash with ethanol or methanol or acetone with a concentration of 80% or more, filter, dry at 60-80°C, and then place it in a heating furnace at 200-800 Decompose by heating at ℃ for 1 to 4 hours to obtain nanomete...

Embodiment 3

[0038] Example 3, at room temperature, 1 molar amount of solid zinc oxide and 1 to 2 molar amounts of solid ammonium bicarbonate or ammonium carbonate and 3-5 molar amounts of ammonia water NH 3 ·H 2 O mixed, react at room temperature until the solid zinc oxide is completely dissolved; while stirring, add dropwise a solution of ammonium sulfide or sodium sulfide with a concentration of 0.1-1mol / l until a white precipitate just appears, and obtain refined tetraammonium carbonate after filtration Zinc (II) complex solution; then add a total weight of 0.3-8% surfactant to the above solution, place the solution in a water bath at 40-50°C, place it under stirring for 8-24 hours, and then filter to obtain For basic zinc carbonate precipitation, wash and filter with ethanol or methanol or acetone with a concentration of more than 80%, and then dry at 60°C; put the dried precipitate into a heating furnace, and heat and decompose it at 200-800°C1 ~ 4 hours to obtain nanometer zinc oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com