Chloride assisted hydrometallurgical extraction of metal

a hydrometallurgical extraction and chloride technology, applied in the direction of inorganic chemistry, silver compounds, dissolving, etc., can solve the problems of large acid production quantities, expensive neutralization, and unfavourable low-grade concentrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The process according to the invention is flexible enough to treat a range of copper concentrates in which the grade of copper varies from low, i,e. about 15% copper or less, to high grade, i.e. about 35% copper or more.

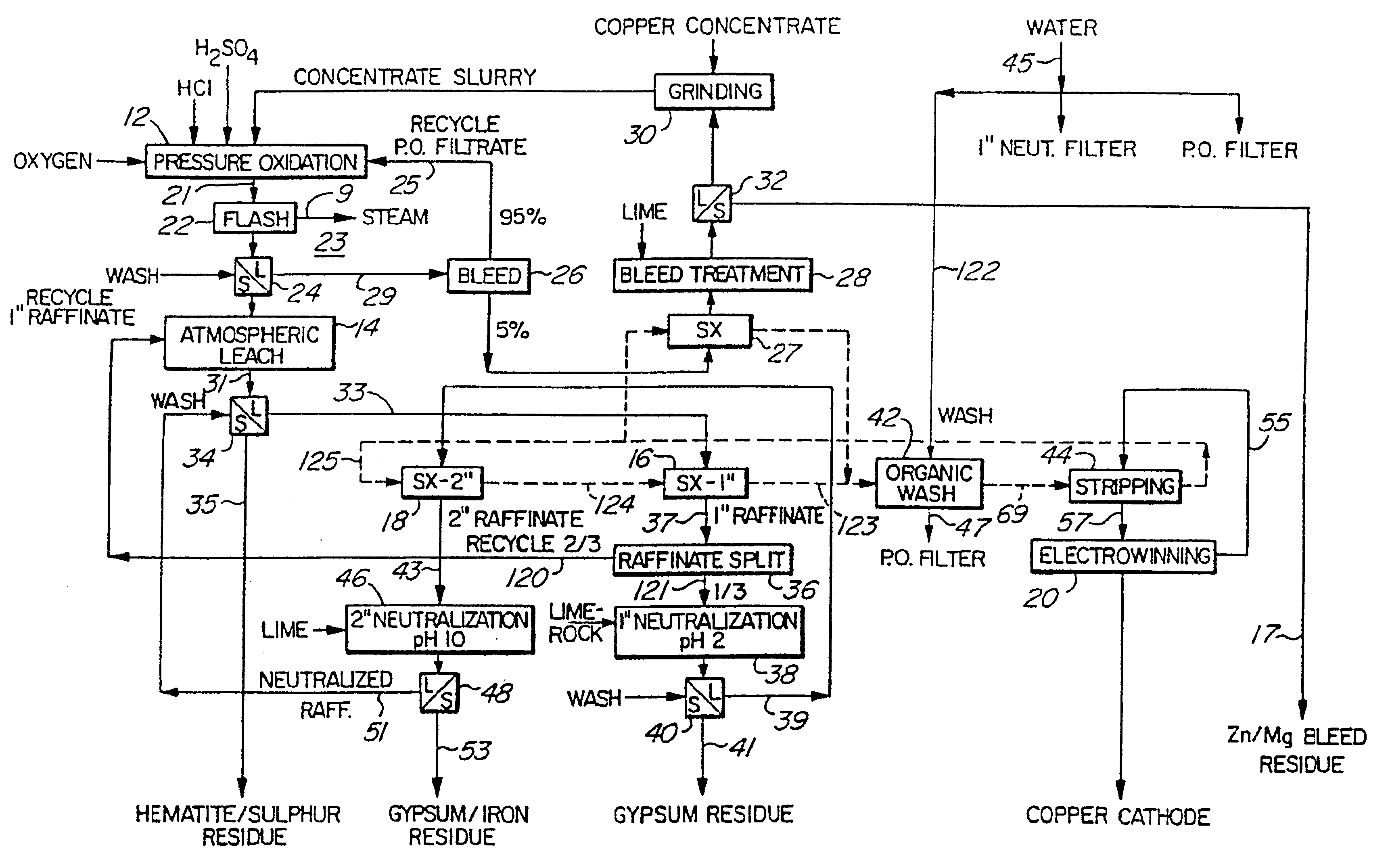

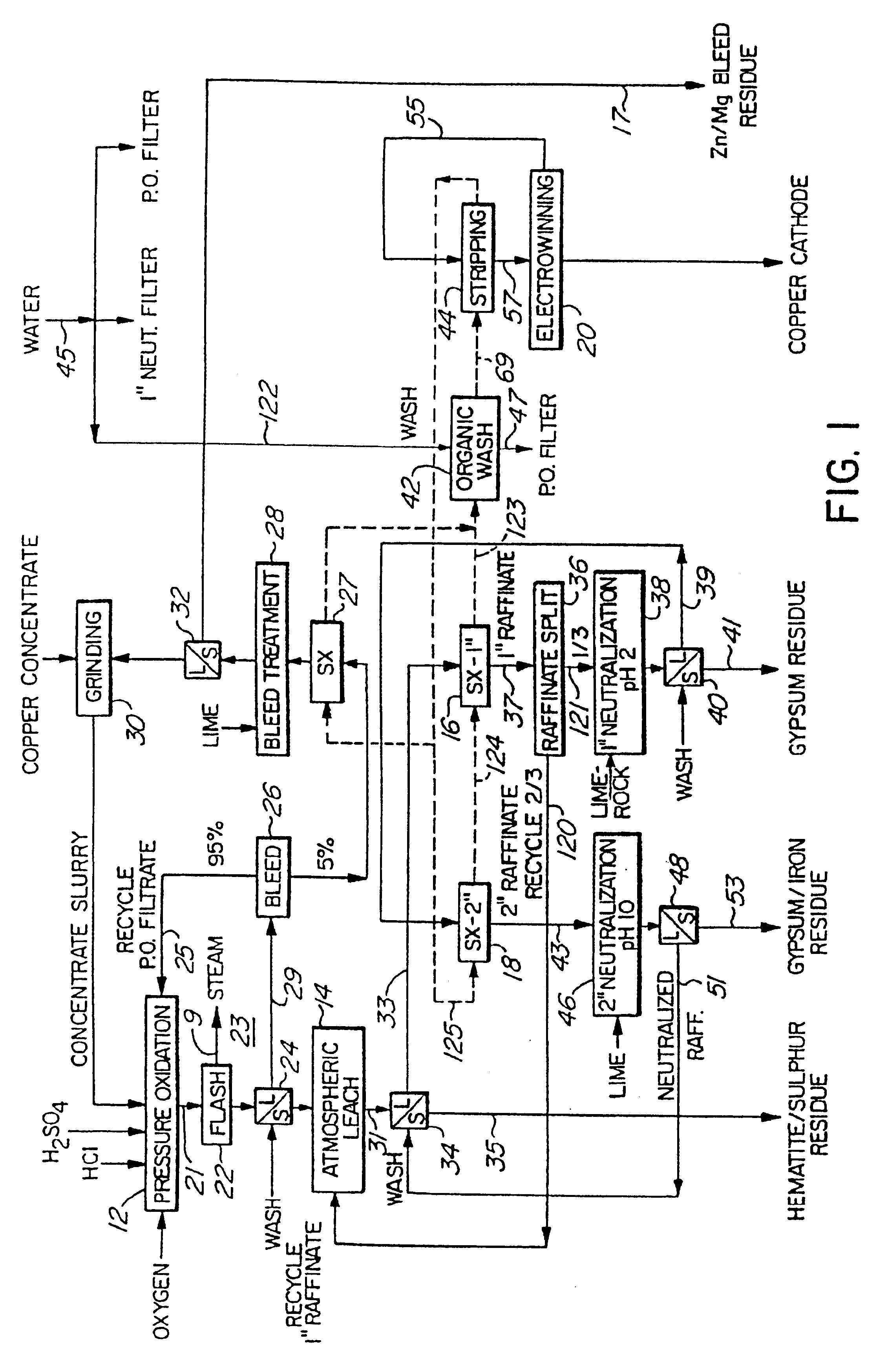

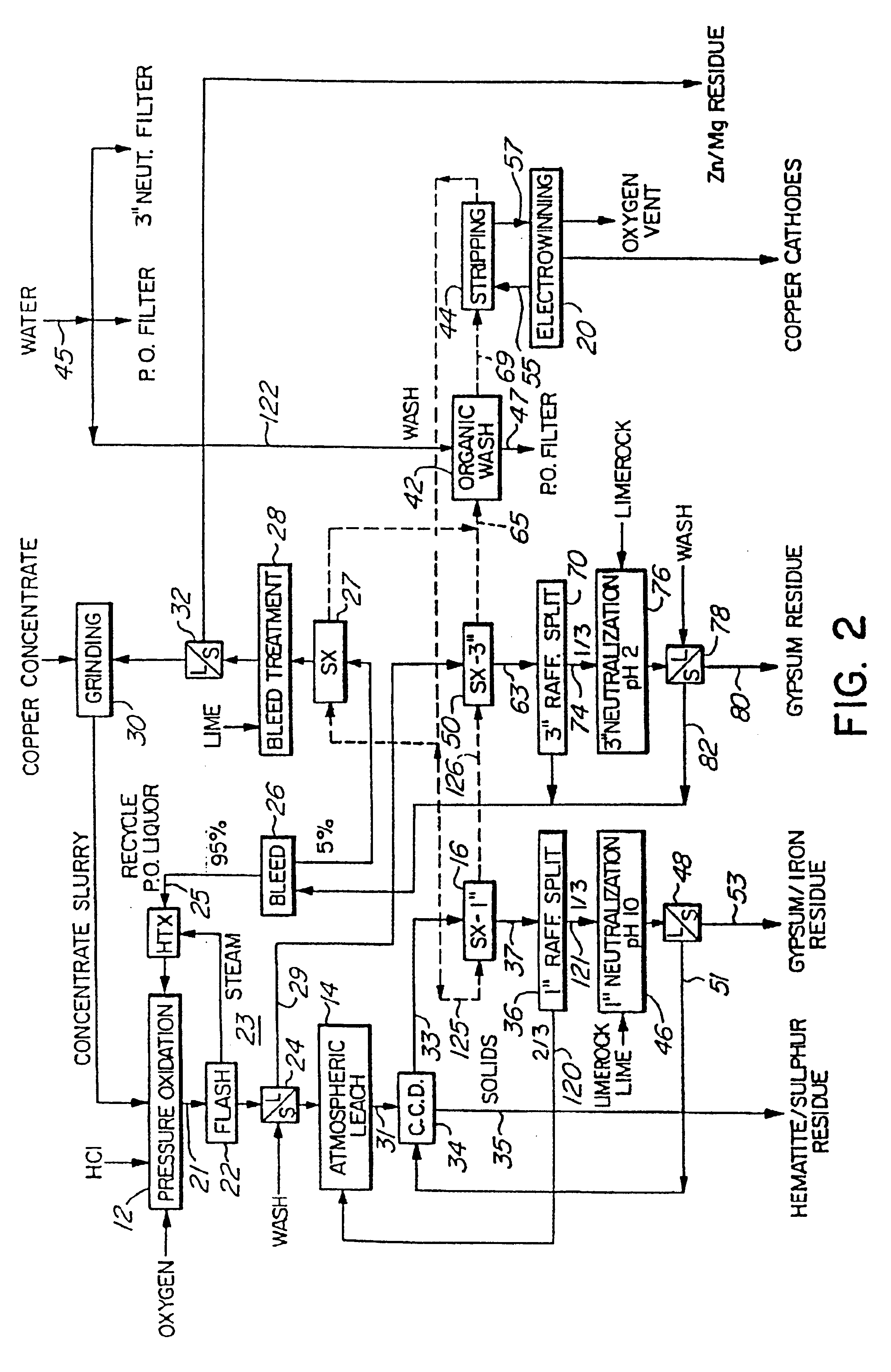

Broadly, the process comprises a pressure oxidation stage, an atmospheric leach stage, one or more solvent extraction stages and an electrowinning stage. Different grades of concentrate require different treatment in the pressure oxidation stage, requiring different modes of operation. These modes of operation are termed Mode A and Mode B, respectively. In Mode A, which is effective when high grade copper ores are leached, copper is not leached in the pressure oxidation stage. In Mode B, which is effective when medium and low grade copper ores are leached, copper is leached in the pressure oxidation stage.

Each of the two modes of operation will now be described in turn.

Process Mode A

FIG. 1 is a flow diagram of Mode A. The process comprises a pressure oxidation stage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| chloride concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com