All-wet process pretreatment method for copper anode mud

A copper anode slime and pretreatment technology, applied in the direction of improving process efficiency, can solve the problems of large copper anode slime processing capacity, reducing precious metal recovery rate, low production capacity, etc., achieving low pollution, reducing processing capacity and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

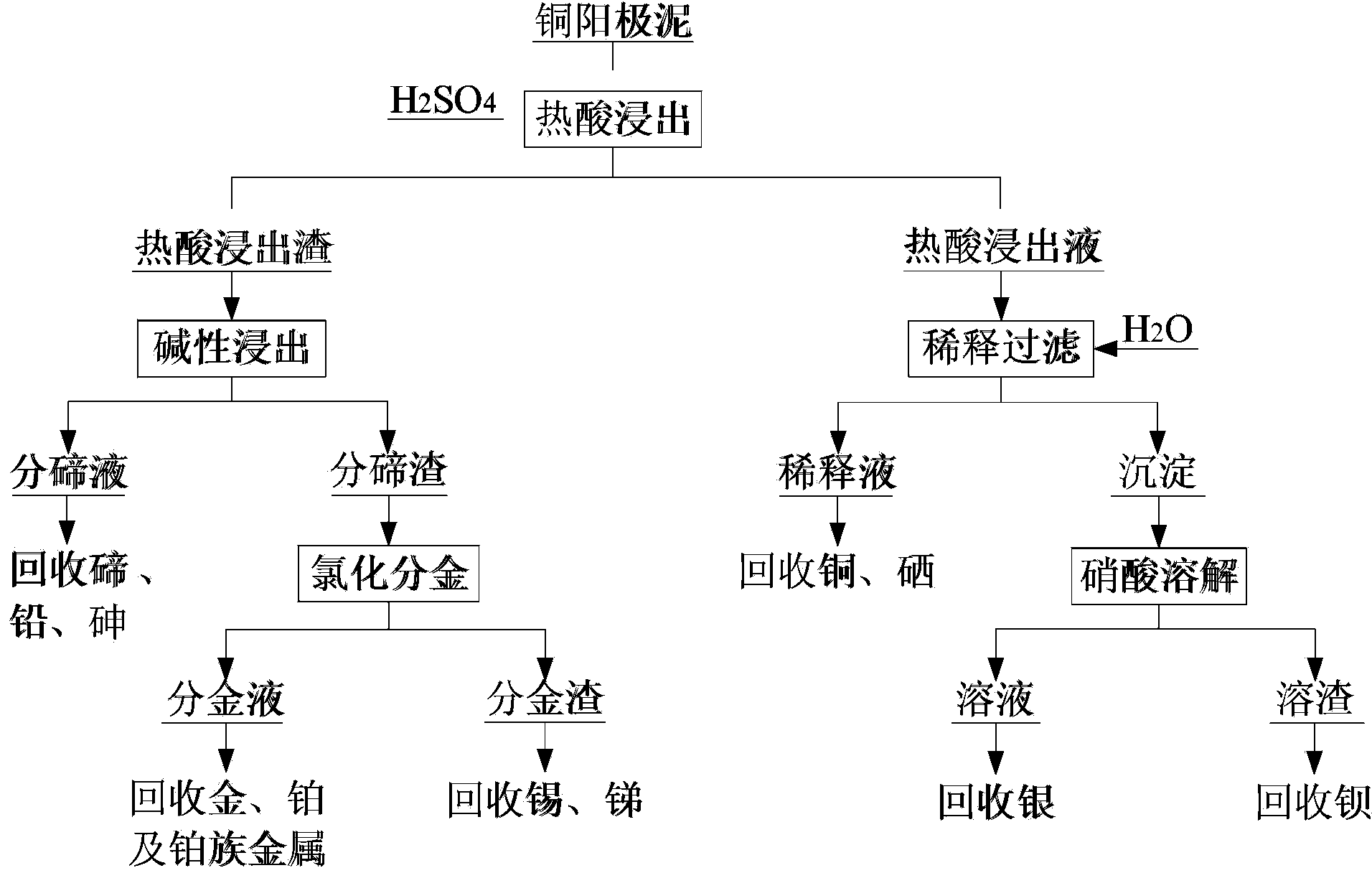

Method used

Image

Examples

Embodiment 1

[0023] Copper anode slime is dried at 80°C for later use, and its main components are (%) by weight percentage: Au0.335, Ag8.64, Cu9.73, Se4.85, Te4.53, Pb12.36, As3.51 , Sb3.52, Ba12.33, Sn0.65.

[0024] Add 1.0L of concentrated sulfuric acid to 500g of copper anode slime, stir at 200°C for 50 minutes, and filter to obtain 1.1L of hot acid leaching solution and 298.5g of hot acid leaching residue.

[0025] The hot acid leaching residue was leached with a sodium hydroxide solution with a concentration of 150g / L, the liquid-solid ratio (sodium hydroxide: hot acid leaching residue) was 2:1, stirred at 60°C for 2 hours, and filtered to obtain 4.0L tellurium solution And 85.6g tellurium separation slag, the main components of tellurium separation liquid are (g / L): Te5.04, Pb14.21, As4.30, the leaching rates of tellurium, lead and arsenic are 89%, 92% and 98% respectively.

[0026] Dissolve the tellurium slag with HCl-NaCl solution, the HCl concentration is 2mol / L, the NaCl concen...

Embodiment 2

[0029] Copper anode slime is dried at 80°C for later use, and its main components are (%) by weight percentage: Au0.476, Ag10.85, Cu12.75, Se6.54, Te8.35, Pb16.76, As5.53 , Sb5.27, Ba15.45, Sn0.78.

[0030] Add 500g of copper anode slime to 1.2L of concentrated sulfuric acid, stir at 350°C for 20 minutes, and filter to obtain 1.25L of hot acid leaching solution and 492.3g of hot acid leaching residue.

[0031] The hot acid leaching slag was leached with a sodium hydroxide solution with a concentration of 160g / L, the liquid-solid ratio (sodium hydroxide: hot acid leaching slag) was 2:1, stirred at 70°C for 3 hours, and filtered to obtain 6.2L tellurium solution And 127.4g tellurium separation slag, the main components of tellurium separation liquid are (g / L): Te6.06, Pb12.57, As4.37, the leaching rates of tellurium, lead and arsenic are 90%, 93% and 98% respectively.

[0032] Dissolve the tellurium slag with HCl-NaCl solution, the HCl concentration is 3mol / L, the NaCl concentr...

Embodiment 3

[0035] Copper anode slime is dried at 80°C for later use, and its main components are (%) by weight percentage: Au0.585, Ag11.34, Cu12.45, Se7.38, Te8.95, Pb12.53, As5.74 , Sb5.77, Ba19.36, Sn0.92.

[0036] Add 0.9L of concentrated sulfuric acid to 500g of copper anode slime, stir at 500°C for 10 minutes, and filter to obtain 0.95L of hot acid leaching solution and 487.4g of hot acid leaching residue.

[0037] The hot acid leaching residue was leached with a sodium hydroxide solution with a concentration of 140g / L, the liquid-solid ratio (sodium hydroxide: hot acid leaching residue) was 2:1, stirred at 90°C for 3 hours, and filtered to obtain 6.9L tellurium solution And 143.5g tellurium separation slag, the main components of tellurium separation liquid are (g / L): Te6.03, Pb8.44, As4.08, the leaching rates of tellurium, lead and arsenic are 93%, 93% and 98% respectively.

[0038]Dissolve the tellurium slag with HCl-NaCl solution, the HCl concentration is 4mol / L, the NaCl conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com