Desulfurized waste water treatment method and system

A technology for desulfurization wastewater and treatment method, which is applied in gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of small area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

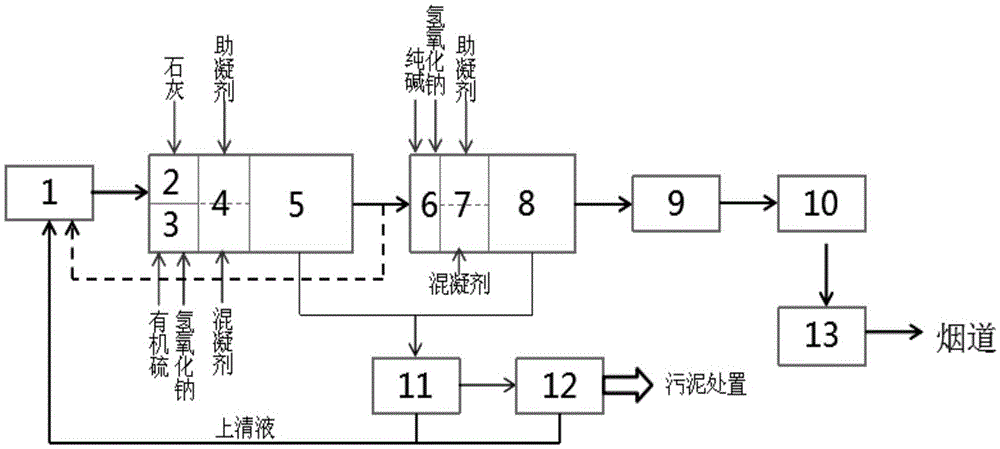

[0026] Aeration adjustment tank 1, pH adjustment tank 2, primary reaction settling tank 3, primary flocculation tank 4, primary clarification tank 5, secondary reaction settling tank 6, secondary flocculation tank 7, secondary clarification tank 8, intermediate Pool 9, multimedia filter 10, sludge balance tank 11, plate and frame filter press 12, spiral atomizing nozzle 13.

[0027] (1) The desulfurization wastewater enters the aeration regulating tank 1, and under the action of the aeration device, the sulfite ions in the desulfurization wastewater are oxidized to sulfate ions to remove some pollutants and reduce the COD of the desulfurization wastewater. The ultrasonic liquid level gauge monitors the liquid level of the aeration regulating tank 1, and automatically controls the operation of the wastewater lifting pump. The desulfurization wastewater is transported to the pH adjustment tank 2 through the wastewater lift pump.

[0028] (2) Add a certain amount of lime to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com