Method for removing nitric oxide from airflow

A technology of nitrogen oxides and gas flow, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high operating cost, low absorption efficiency, low solubility, etc., achieve large processing capacity, simple operation, and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

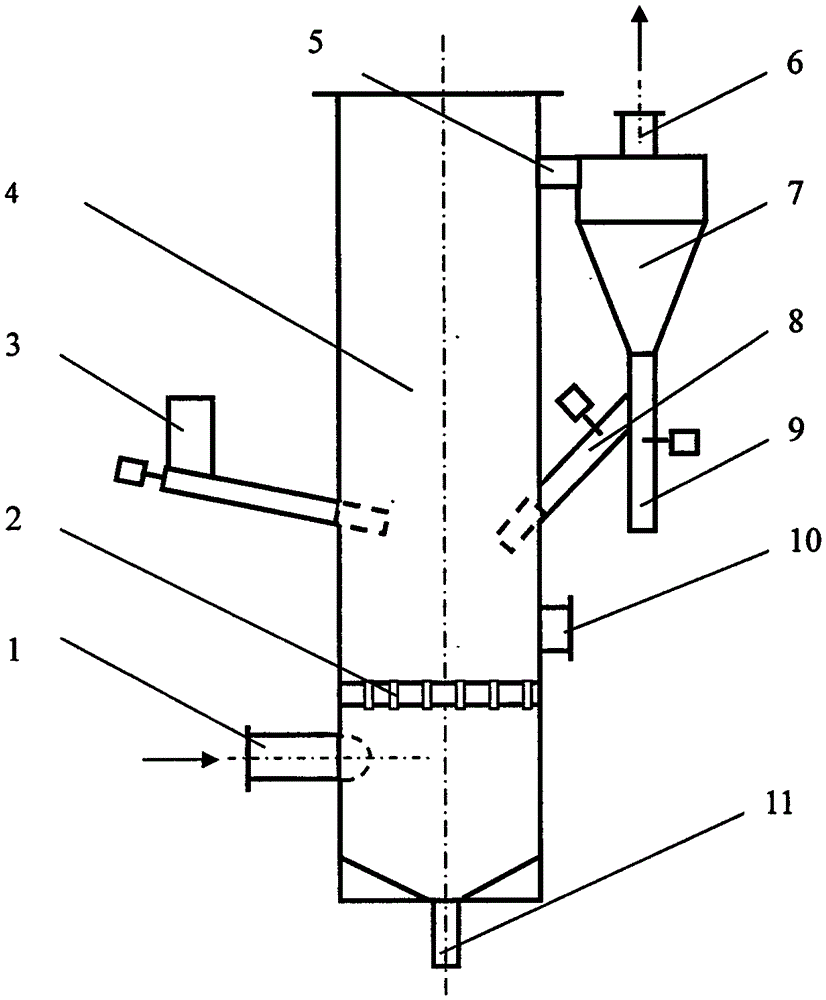

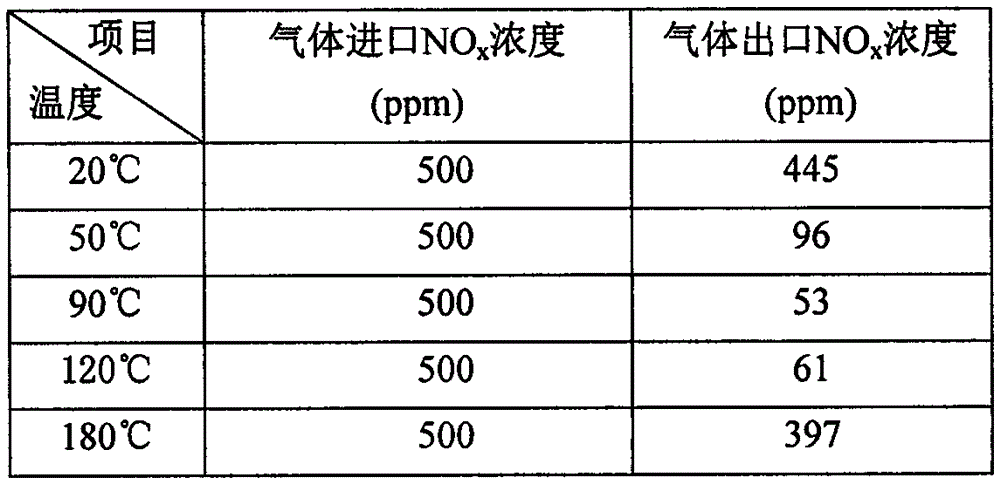

[0017] Embodiment 1: a kind of circulating fluidized bed gas-solid reaction tower device of the method for removing nitrogen oxides from the gas stream is as figure 1 shown. The circulating fluidized bed gas-solid reaction tower has a tower diameter of Φ60 mm, a tower height of 2500 mm, and a tower body made of 316L stainless steel. The concentration of nitrogen oxides (about 90% nitric oxide) in the gas stream is 500 ppm, oxygen is 8% by volume, moisture content is 10% by volume, and the balance is nitrogen. Aluminum chloride is a commercially available industrial-grade powder particle with an average particle size of about 0.1mm. The reaction temperatures are 20°C, 50°C, 90°C, 120°C and 180°C, and the gas-solid contact time in the reaction tower is about 4 -6s. The molar ratio of nitrogen oxides to aluminum chloride is about 1:5. After the gas-solid separator (using a cyclone separator), the reacted solid particles are not returned to the tower. The experimental results ...

Embodiment 2

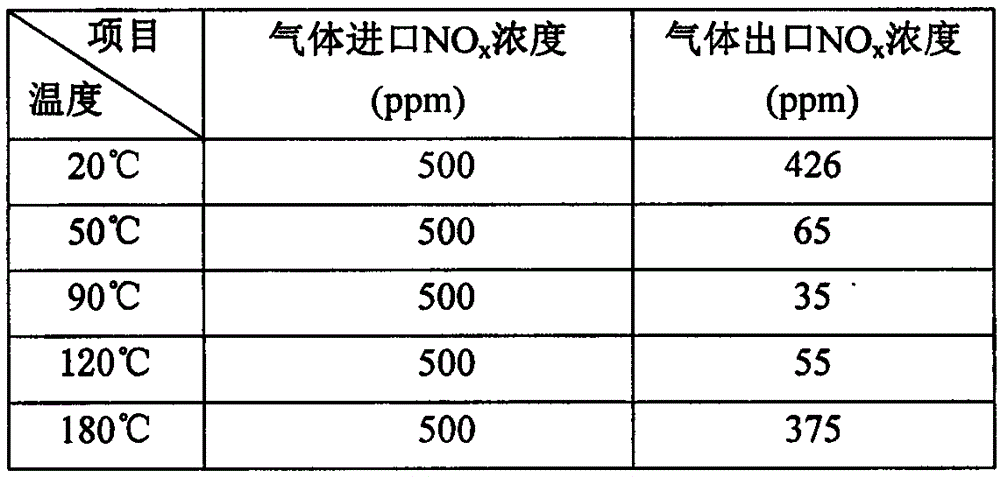

[0020] Example 2: The molar ratio of nitrogen oxides to aluminum chloride is about 1:15. Other conditions are with embodiment 1. The experimental results are shown in Table 2.

[0021] Table 2

[0022]

Embodiment 3

[0023] Embodiment 3: using aluminum chloride particles as the reactant, mixing 20% (volume) of quartz sand with a particle size of about 1mm-3mm in the material, and the molar ratio of nitrogen oxides to aluminum chloride is about 1:15. The reaction temperatures were 50°C, 90°C and 120°C, respectively. Other conditions are with embodiment 1. The experimental results are shown in Table 3.

[0024] table 3

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com