Hot-pressing molding production line for hot-pressed iron blocks

A hot-pressing forming and production line technology, applied in the field of hot-pressing iron-block hot-pressing forming production line, can solve the problems of reducing product quality, affecting steelmaking and cooling cold material forming, and high purchase price, reducing the degree of oxidation of finished products and the range of raw material selection. Wide and reduce the effect of equipment maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

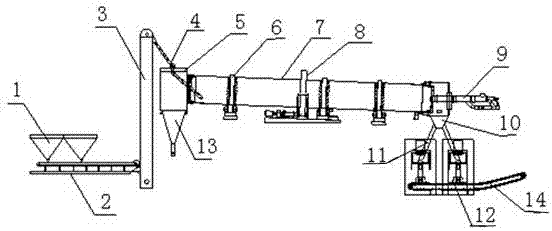

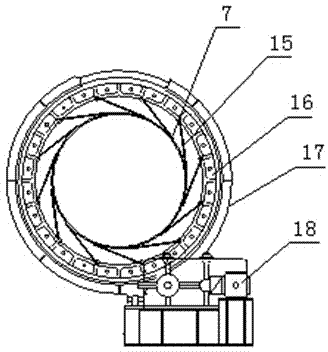

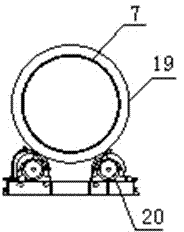

[0029] Refer to attached Figure 1-3 , a production line for hot-pressing hot-pressed iron blocks, comprising a feeding system, a rotary kiln, an unloading and distributing device, a burner 9, a hot-pressing machine 12 and a finished product conveyor 14, and the rotary kiln includes a kiln body 7 and The kiln body rotating device 8, the kiln body 7 has an included angle with the horizontal plane, the kiln body rotating device 8 is fixed on the kiln body 7, the end of the kiln body above the horizontal plane is called the kiln tail, the kiln tail is equipped with a feeding system, the kiln body is low One end on the horizontal plane is called the kiln head, and the kiln head is provided with a feeding and distributing device and a burner 9, and a hot press molding machine 12 and a finished product conveyor 14 are arranged in sequence behind the material guiding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com