Method and device for simultaneous reduction and oxidation of nitrogen oxides from airflow

A technology of nitric oxide and nitrogen oxides, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of expensive medicine, low absorption efficiency, and high operation and use costs, and achieve low operation and use costs and high treatment efficiency. The effect of large quantity and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

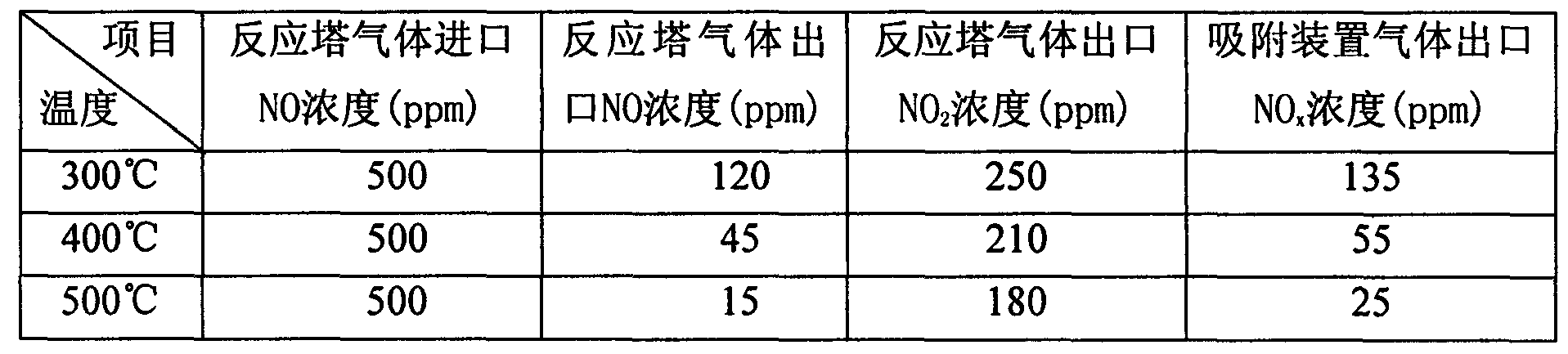

Embodiment 1

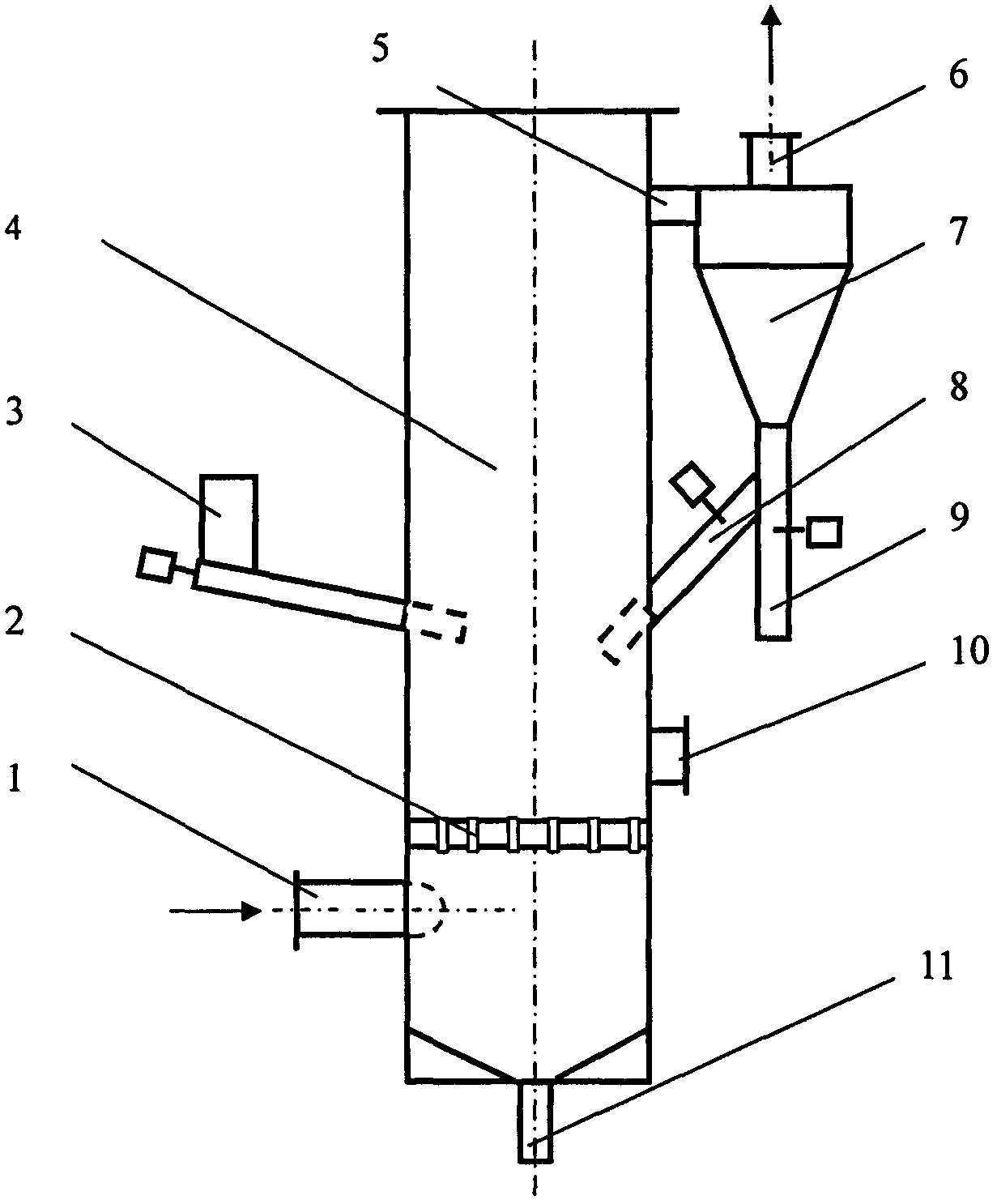

[0020] Embodiment 1: A kind of circulating fluidized bed gas-solid reaction tower device of reducing and oxidizing nitrogen oxides method simultaneously from the gas stream such as figure 1 shown. The diameter of the reaction tower is Φ600mm, the tower height is 4000mm, and the material of the tower body is 316L stainless steel. The gas flow is introduced from the gas inlet at the lower part of the tower, passes through the gas distributor and the gas-solid reaction zone, and is discharged from the connecting pipe at the upper part of the tower through the gas outlet of the cyclone separator. The concentration of nitric oxide in the gas stream is 500ppm, the concentration of oxygen is 6%, and the balance is nitrogen. Ferrous chloride powder particles are used as the reactant, the average diameter is 0.2mm-0.5mm, the reaction temperature is 300°C, 400°C and 500°C respectively, the gas-solid contact time in the reaction tower is 2s, nitrogen oxides and chlorine The molar ratio...

Embodiment 2

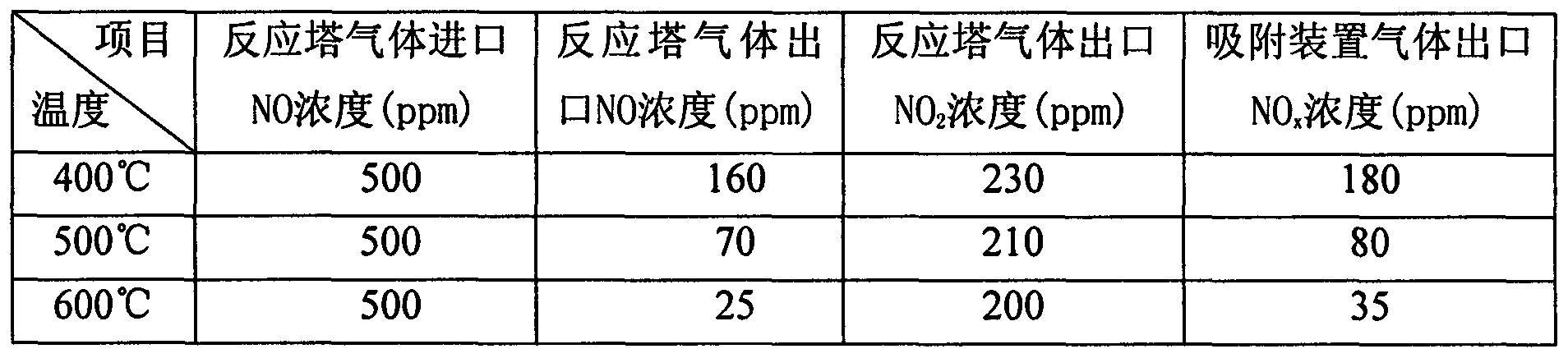

[0024] Example 2: Using ferric chloride powdery particles as the reactant, the average diameter is 0.2mm-0.6mm, the reaction temperatures are 400°C, 500°C and 600°C respectively, the gas-solid contact time in the reaction tower is 2s, nitrogen oxidation The molar ratio of compound to ferric chloride is 1:2. Other conditions are with embodiment 1.

[0025] Experimental results: as shown in Table 2.

[0026] Table 2

[0027]

Embodiment 3

[0028] Example 3: Using manganese chloride powdery particles as the reactant, the average diameter is 0.3mm-0.6mm, the reaction temperatures are 450°C, 550°C and 650°C respectively, the gas-solid contact time in the reaction tower is 3s, nitrogen oxidation The molar ratio of compound to manganese chloride is 1:4. Other conditions are with embodiment 1.

[0029] Experimental results: as shown in Table 3.

[0030] table 3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com