Electrochemical purification method for molten salt

An electrochemical and molten salt technology, applied in the field of electrochemical purification of molten salt, can solve problems such as difficult to achieve impurity removal effect, harsh equipment conditions, and inability to accurately control the reaction potential of cathode and anode, so as to achieve less consumption of materials and energy , Simple and convenient operation, short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

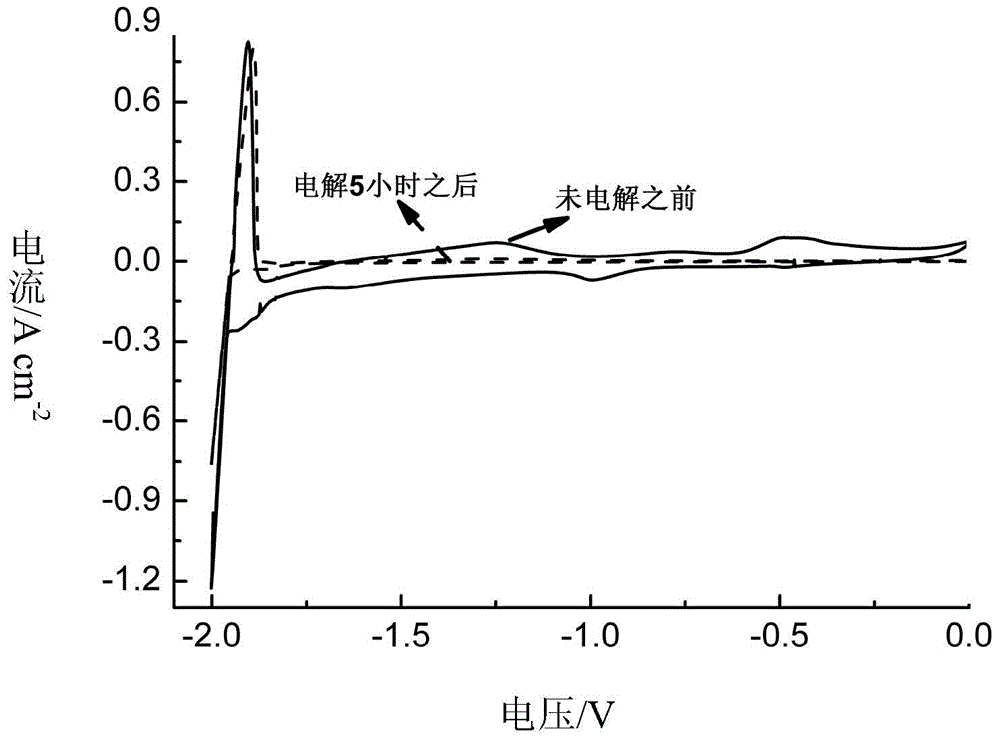

Embodiment 1

[0032] Example 1: The type of molten salt to be purified is LiF-NaF-KF eutectic molten salt (FLINAK, melting point 454° C., boiling point 1570° C.), and the ratio is 46.5:11.5:42 (mol%). The system purification treatment temperature is 550°C, the main cationic impurities in the molten salt to be purified are metal ions such as iron, nickel, chromium, aluminum, etc., and the total mass percentage of impurity cations is not more than 1%.

[0033] The molten salt electrochemical purification method mainly includes the following steps:

[0034] (1) Put the molten salt to be purified in a cylindrical graphite crucible. High-density graphite material is used, and the molten salt loading is about 2 cm in liquid height when molten.

[0035] (2) The crucible and molten salt are placed in a closed molten salt electrochemical experimental device (the device was developed by the Shanghai Institute of Applied Physics, Chinese Academy of Sciences, prepared according to the method reported ...

Embodiment 2

[0044] Example 2: The type of molten salt to be purified is LiF-NaF-KF eutectic molten salt (FLINAK, melting point 454° C., boiling point 1570° C.), and the ratio is 46.5:11.5:42 (mol%). The purification treatment temperature of the system is about 550°C. The main cationic impurities in the molten salt to be purified are iron, nickel, chromium, aluminum and other metal ions, and the main anionic impurities are oxygen ions. Wherein, the total mass percentage of cationic impurities is not more than 2%, and the total mass percentage of anionic impurities is not more than 1%.

[0045] The molten salt electrochemical purification method mainly includes the following steps:

[0046] (1) Put the molten salt to be purified in a cylindrical graphite crucible. High-density graphite material is used, and the molten salt loading is about 2 cm in liquid height when molten.

[0047] (2) The crucible and molten salt are placed in a closed molten salt electrochemical experimental device (th...

Embodiment 3

[0059] Example 3: The type of molten salt to be purified is LiCl-KCl eutectic molten salt (melting point 355° C.), and the proportion is 59:41 (mol%). The purification treatment temperature of the system is about 450°C. The main cation impurities in the molten salt to be purified are metal ions such as iron, nickel, chromium, aluminum, etc., and the total mass percentage of impurity cations does not exceed 3%.

[0060] The molten salt electrochemical purification method mainly includes the following steps:

[0061] (1) Put the molten salt in a cylindrical corundum crucible. The loading amount of molten salt is about 2 cm of liquid height when molten.

[0062] (2) The crucible and molten salt are placed in a closed molten salt electrochemical experimental device (the device was developed by the Shanghai Institute of Applied Physics, Chinese Academy of Sciences, prepared according to the method reported in the Chinese patent application number: 201320023881.X), and the external...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com