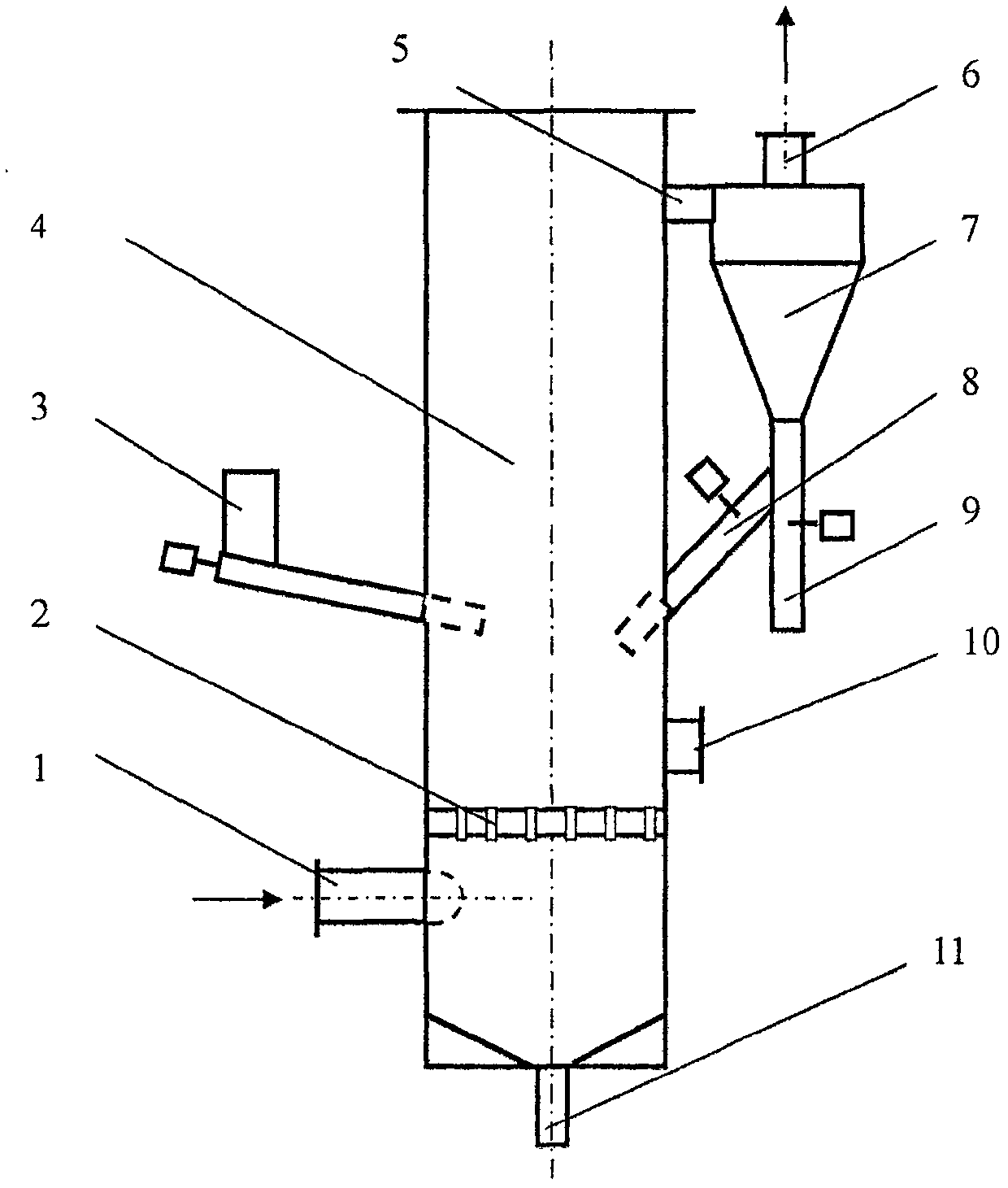

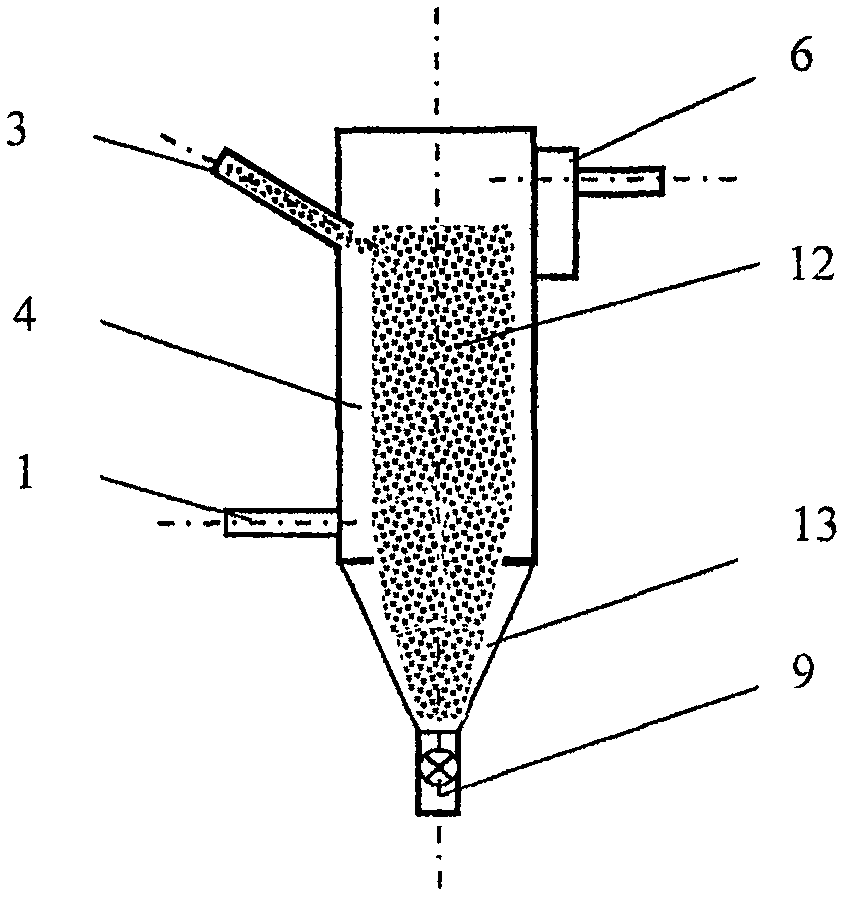

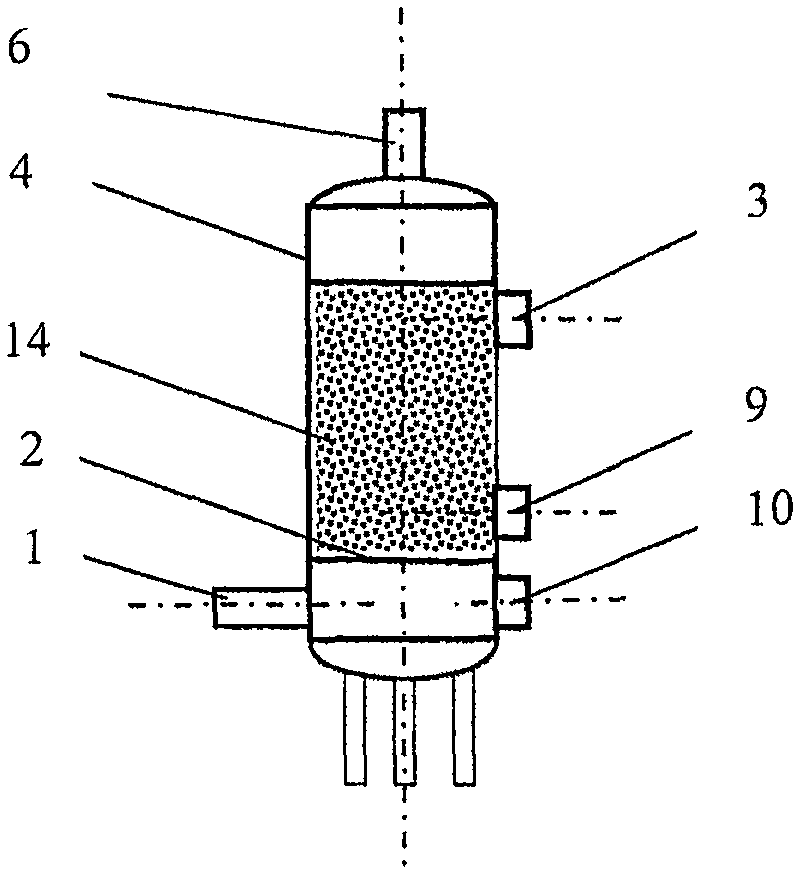

Method and device for preparing and purifying carbon dioxide adsorbent

A technology of carbon dioxide and adsorbent, which is applied in the fields of air pollution control and related environmental protection, and can solve the problems of not being able to be popularized on a large scale, easy to deteriorate, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: a kind of preparation method of described sorbent: ferrous sulfate, sodium hydroxide and water are added mixed reactor and mixed in the ratio of about 1: 0.1: 2 (molar ratio, the same below), after the completion of the reaction ( About 10-30 minutes, the same below, different materials), dry and activate in the air, the drying temperature is about 40-60 ° C, the time is about 3 hours, remove the moisture in the material, and then activate, activate The temperature is about 120°C. When the gas components in the gas flow no longer change, the activation is completed, and the obtained solid product is an adsorbent according to the present invention.

Embodiment 2

[0040] Embodiment 2: a kind of preparation method of described adsorbent: add cobalt sulfate heptahydrate and sodium hydroxide into mixing reactor and mix by about 1: 1 ratio, after the completion of the reaction, carry out drying and activation in air, drying temperature The temperature is 60-95°C, the time is about 2 hours, the moisture in the material is removed, and then activated, the activation temperature is about 150°C, when the gas composition in the gas flow no longer changes, the activation is completed, and the obtained solid product is An adsorbent according to the present invention.

Embodiment 3

[0041] Embodiment 3: a kind of preparation method of described sorbent: add ferrous sulfate heptahydrate and sodium hydroxide into mixing reactor and mix in about 1: 2 ratio, after the completion of the reaction, dry and activate in nitrogen, dry The temperature is the same as in Example 2, the activation temperature is about 250° C., and the time is about 2 hours. The obtained solid product is an adsorbent according to the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com