Desulfurizing duster

A technology for desulfurization and dust removal and shell, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separating agents, etc., can solve the problems of incomplete smoke and dust removal, unsatisfactory desulfurization and dust removal effect, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

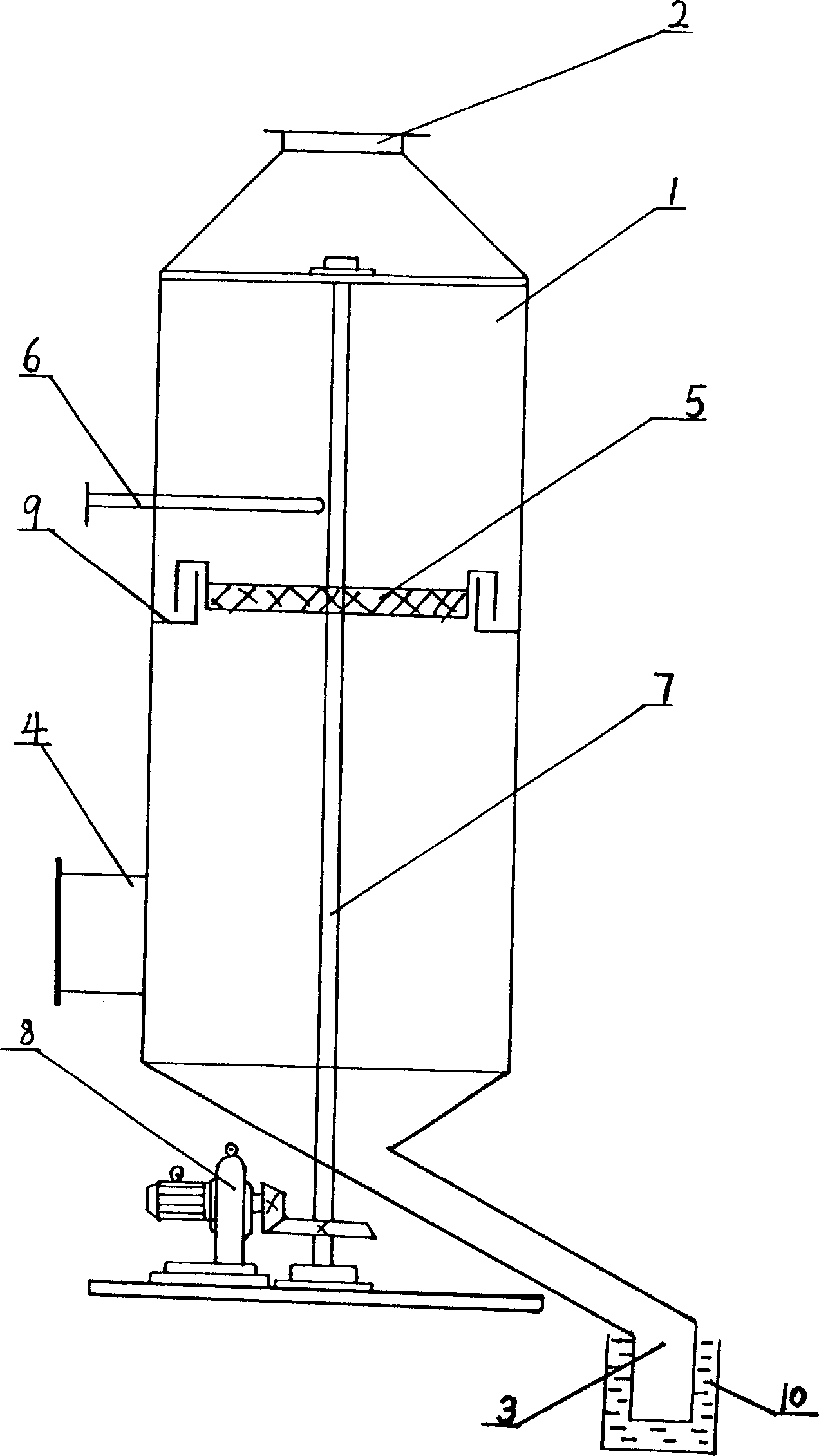

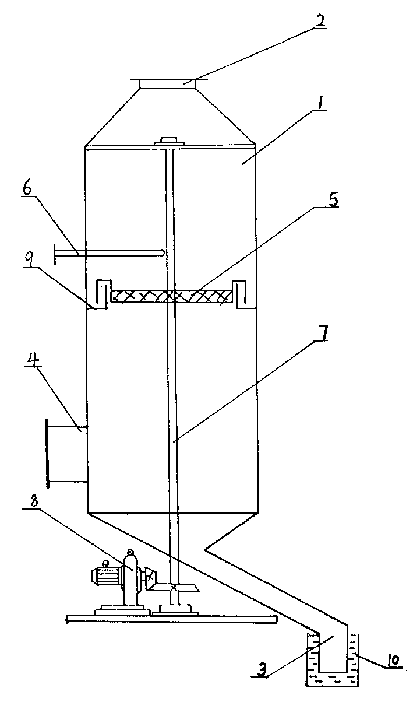

[0012] The top of the casing 1 is provided with an exhaust port 2, and the bottom is provided with a drain pipe 3. The end of the drain pipe 3 is immersed in the water in the pool 10 for water sealing to prevent air leakage during operation. The inside of the casing 1 is located above the air inlet 2. There is a vapor-liquid filter 5, which is horizontally fixed on the vertical shaft 7 driven by the power mechanism 8, and rotates horizontally with the vertical shaft 7 to filter and remove smoke and harmful gases that are bound by water mist. It is sealed and buckled with the water seal groove 9 provided on the inner wall of the housing 1, and is used to prevent the flue gas from bypassing. The cleaning flushing pipe 6 spraying downward is arranged above the vapor-liquid filter 5, the vapor-liquid filter 5, and the water seal groove 9 1. Clean the flushing pipe 6 to form a filter and purification layer, and the top of the housing 1 is the exhaust port 2 .

[0013] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com