Carbon tetrachloride polluted water source treatment device and application thereof

A carbon tetrachloride and treatment device technology, applied in the field of water treatment, can solve the problems of less practical application, no industrial device, high use cost, etc., and achieve the effects of convenient operation and maintenance, easy construction and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

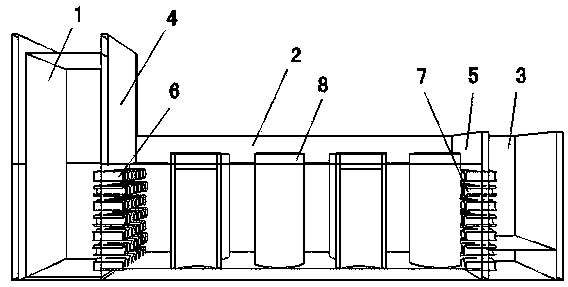

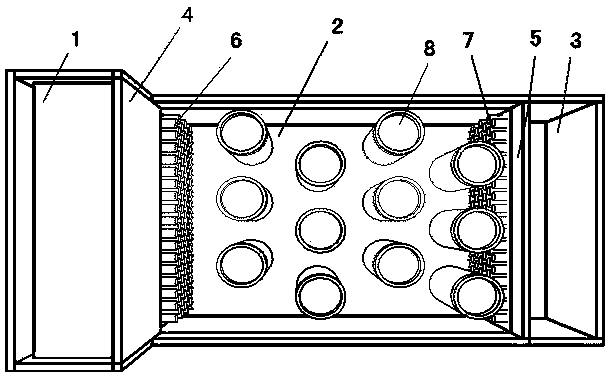

[0071] Wash 20kg of river sand and dry it, pass a 60-mesh screen to obtain 0.25mm fine sand. Lay the fine sand on the bottom of the simulated soil layer box 2 with a thickness of 10cm; pass 60kg of matrix material soil through a 24-mesh screen Obtain fine soil with a particle size of 0.07mm, and pave the fine soil on the fine sand with a thickness of 30 cm; pass 60 kg of matrix material clay through a 5000-6000 mesh sieve to obtain fine clay with a particle size of 0.01-0.02 mm. The clay is laid on top of fine soil with a thickness of 30 cm.

[0072] A carbon tetrachloride solution with a concentration of 120 μg / L is prepared and injected into the water inlet tank 1 so that the water level is 70 cm higher than the fine clay.

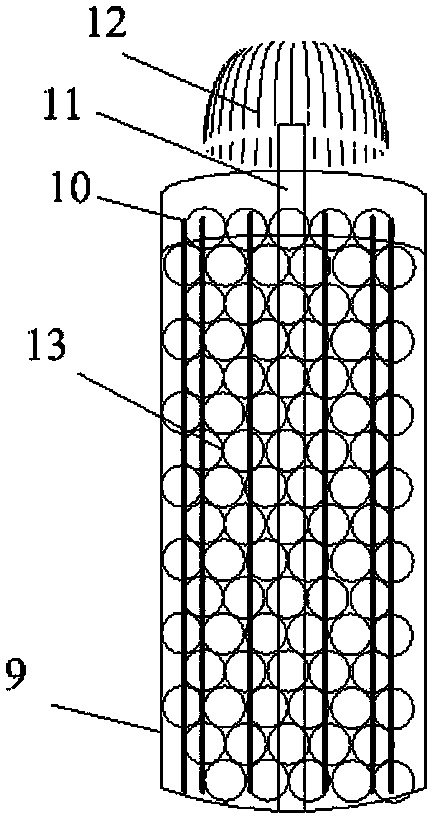

[0073] The filler 13 is made of 100 mesh iron powder, 300 mesh coke powder, and 50 mesh copper powder, mixed according to the ratio of 1:0.5:0.05, adjusted by acid and alkali to set the pH to 10, and then loaded into the reaction well casing group 8 The temp...

Embodiment 2

[0077] As in Example 1, the others remain unchanged. The filler 13 uses 50 mesh iron powder, 300 mesh charcoal powder, and 10 mesh zinc powder, and mix them in a ratio of 1:1:0.01. Adjust the pH to 10 through acid-base adjustment, and then Load into the reaction well casing group 8, set the temperature of the reaction well to 9°C through the heating rod group 10, set the pH to 10 through acid-base adjustment, and turn on the water pump to form a circulating flow of water in the reaction well.

[0078] The removal rate of carbon tetrachloride in the carbon tetrachloride solution of this embodiment reached 90%.

Embodiment 3

[0080] As in Example 1, the others remain unchanged. The filler 13 is selected from 10 mesh iron powder, 500 mesh coconut shell charcoal powder, and 100 mesh lead powder, mixed in a ratio of 1:2:0.005, and the pH is set to 10 through pH adjustment. , Then put it into the reaction well casing group 8, set the temperature of the reaction well to 50°C through the heating rod group 10, set the pH to 7 through acid-base adjustment, and turn on the water pump to form a circulating flow of water in the reaction well.

[0081] The removal rate of carbon tetrachloride in the carbon tetrachloride solution of this embodiment reached 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com