Flash sintering method of low-temperature flash sintering ceramic and obtained ceramic and device thereof

A technology of rapid sintering and sintering method, applied in the field of ceramic sintering, can solve the problems of incomplete sintering mechanism of SPS, inability to make shaped products, less production of ceramic products, etc., to achieve superior ceramic quality, shorten sintering time, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

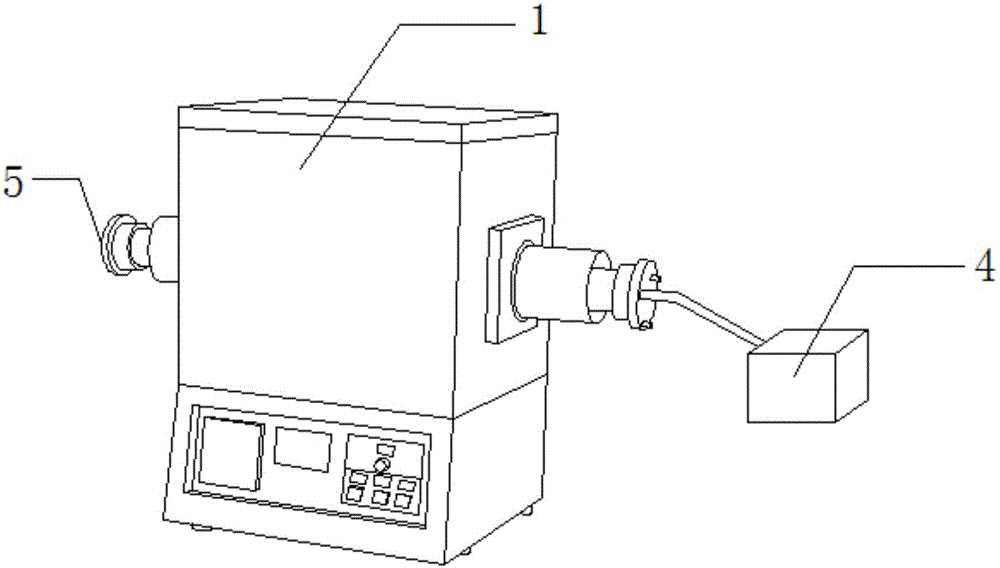

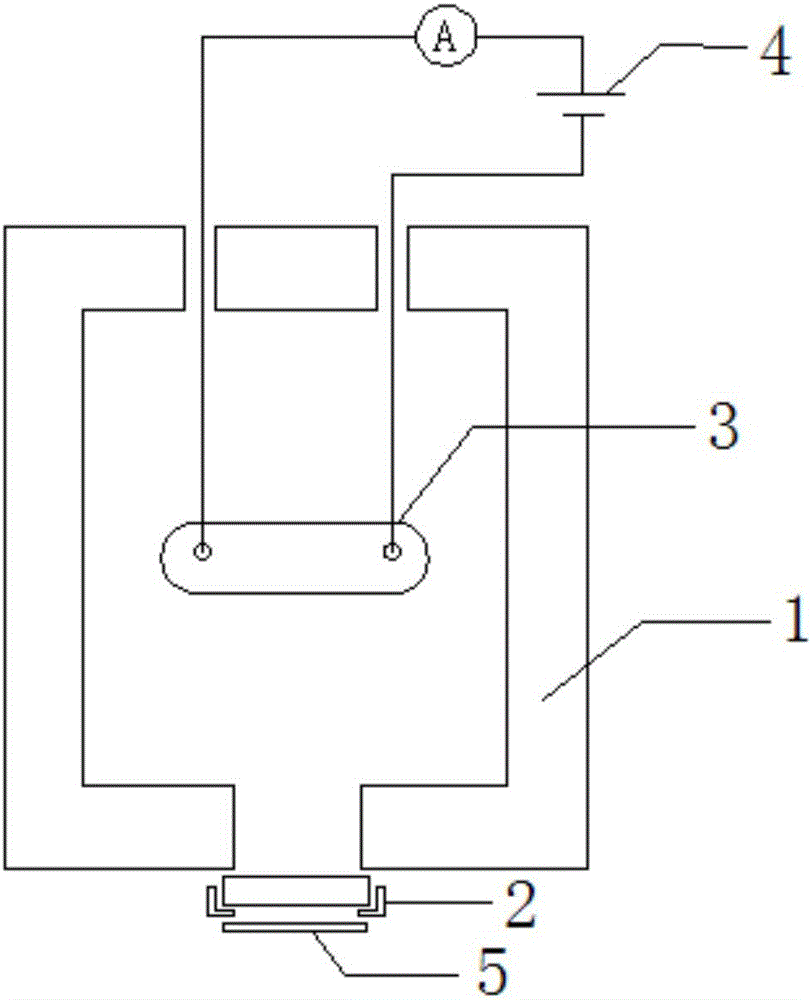

[0046] The present invention provides a set of devices for implementing the flash sintering method of low-temperature rapid sintering ceramics, and the device is a set of flash sintering furnace (MX-100). On the basis of this equipment, flash sintering of ceramics can be carried out.

[0047] MX-100 consists of a tube furnace 1, a flange cooling device 2, an electrode 3, a power supply 4, an observation window 5, and an image data acquisition and processing system connected to the observation window. Tube Furnace 1 can prepare non-oxide ceramics in the sealed atmosphere mode, and can prepare oxide ceramics in the non-sealed mode, and the maximum temperature can reach 1700 degrees Celsius, so it can meet the preparation of most oxidized and non-oxidized ceramics need.

[0048] An observation window 5 is added to the flange of the inlet end of the tube furnace 1, which can be used for image observation in the experiment; a platinum electrode is installed on the flange of the ga...

Embodiment 2

[0052] Utilize the device among the embodiment 1 to sinter the ceramic green body, concrete steps are as follows:

[0053] First, use cold isostatic pressing to press the ceramic green body of zirconia ceramic nano powder under the pressure of 200MPa. The purity of zirconia ceramic powder is 99.95%, the average particle size is 160nm, and the density of the ceramic green body after cold isostatic pressing is 60%. , the thickness is 1cm;

[0054] Drill holes at both ends of the green body, and insert platinum electrodes into the holes to wrap and fix the green body. The distance between the electrodes is about 100mm;

[0055] Connect the electrode to the DC power supply with wires, turn on the power supply, set the power supply to 200V / cm, and set the current upper limit to 0.5A;

[0056] Set the tube furnace heating program: start from room temperature, heat up to 1000 degrees Celsius at a rate of 8 degrees Celsius per minute, and then heat up to 1400 degrees Celsius at a rat...

Embodiment 3

[0063] Utilize the device among the embodiment 1 to sinter the ceramic green body, concrete steps are as follows:

[0064] First, use cold isostatic pressing to press the ceramic green body of silicon carbide ceramic nanopowder under the pressure of 200MPa. The purity of silicon carbide ceramic powder is 99.5%, the average particle size is 80nm, and the density of ceramic green body after cold isostatic pressing is 55%. , the thickness is 2mm;

[0065] Drill holes at both ends of the ceramic green body, and insert platinum electrodes into the holes to wrap and fix the green body. The distance between the electrodes is about 100mm;

[0066] Connect the electrode to the DC power supply with wires, turn on the power supply, set the power supply to 1000V / cm, and set the current upper limit to 0.5A;

[0067] Set the tube furnace heating program: start from room temperature, heat up to 1000 degrees Celsius at a rate of 8 degrees Celsius per minute, and then heat up to 1650 degrees ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com