Design and manufacturing method used for selective laser sintering sand mould regional strength change

A technology of laser selective sintering and manufacturing method, which is applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of difficult realization and complicated scanning trajectory division, and achieves improved sintering efficiency, improved sand mold design, and improved adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the practical application of the invention is not limited to the following embodiments.

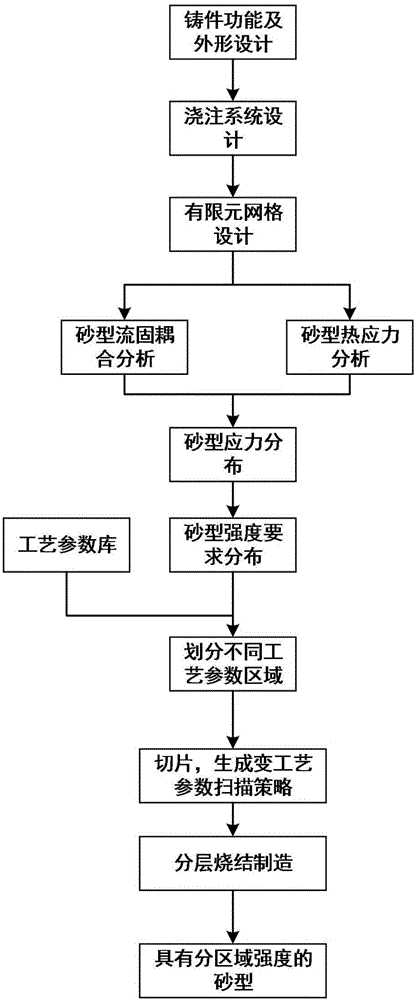

[0022] refer to figure 1 , a method for designing and manufacturing laser selective sintering sand molds with variable strength in different regions, comprising the following steps:

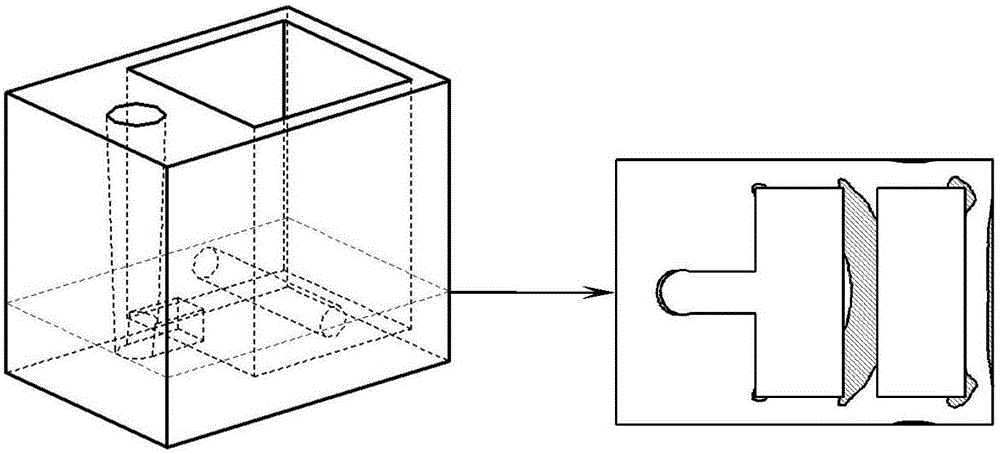

[0023] 1) Design a three-dimensional model of the gating system with a gating riser according to the shape characteristics of the casting parts;

[0024] 2) Divide the three-dimensional model of the gating system into finite element models for numerical simulation;

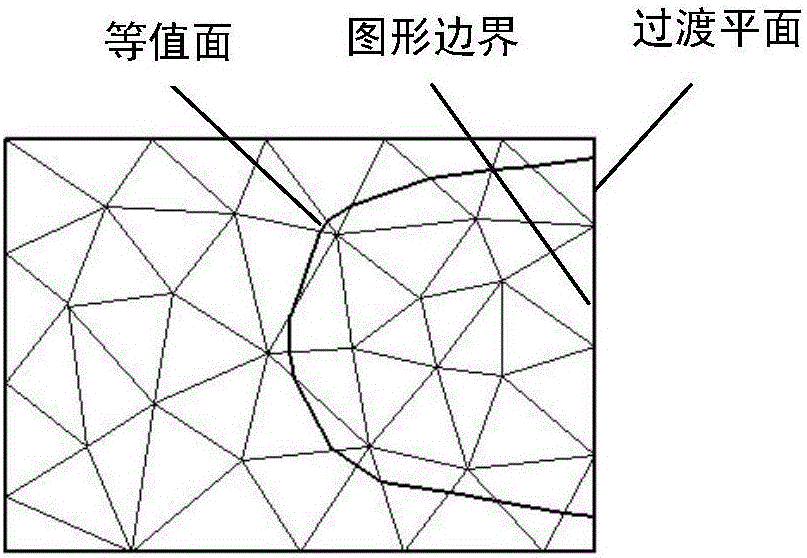

[0025] 2.1) Generate a consistent grid at the interface between the casting and the sand mold, and additionally generate the surface unit of the interface. The main body of the grid is a tetrahedral grid, and the interface is set as an expansion layer. The unit type is selected as a triangular prism unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com