Method for preparing low-density ITO evaporation target material

A low-density, target technology, applied in the field of preparation of ITO oxide evaporation materials, can solve the problems of high production cost and risk, and achieve the effects of reducing production cost and risk, reducing preparation process, and reducing sintering pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

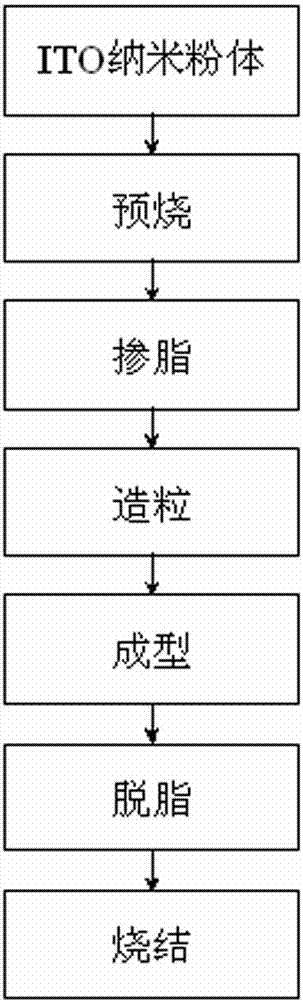

Method used

Image

Examples

Embodiment 1

[0038] Among ITO powder raw materials, In 2 o 3 : SnO 2 The weight ratio is 90%:10%, the average particle size D50 of the powder is 120nm, and the specific surface area is 11.6m 2 / g. The ITO powder was placed in a high-temperature calciner, and sintered in an oxygen atmosphere at normal pressure at a temperature of 1550° C. for 6 hours. The sintered ITO powder was mixed with 3wt% PVA and dried at 80°C. Put the fat-mixed ITO powder into a stainless steel mold, and hold the pressure at 40MPa for 3 minutes to form. Put the ITO biscuit into the degreasing furnace, degrease at 600°C, and keep it warm for 10 hours. The degreased ITO biscuit was put into a high-temperature sintering furnace, and sintered in an oxygen atmosphere at normal pressure at a temperature of 1400° C. for 10 hours. The density of the ITO evaporation target is 61.5%, and the resistivity is 5.3×10 -3Ω·cm. When the electron beam voltage is 7.5kV and the beam current is 15mA, the film thickness is 250nm, ...

Embodiment 2

[0040] Among ITO powder raw materials, In 2 o 3 : SnO 2 The weight ratio is 90%:10%, the primary particle size D50 of the powder is 105nm, and the specific surface area is 12.4m 2 / g. The ITO powder was placed in a high-temperature sintering furnace, and sintered in an oxygen atmosphere at normal pressure at a temperature of 1530° C. for 6 hours. The sintered ITO powder was mixed with a total amount of 3wt% of PVA and liquid paraffin, and then dried at 80°C. Put the fat-mixed ITO powder into a stainless steel mold, and hold the pressure at 40MPa for 3 minutes to form. Put the ITO biscuit into a high-temperature furnace, degrease at 600°C, and keep it warm for 10 hours. The degreased ITO biscuit was put into a high-temperature furnace, and sintered in an oxygen atmosphere at normal pressure at a temperature of 1480° C. for 8 hours. The density of the ITO evaporation target is 62.2%, and the resistivity is 6.3×10 -3 Ω·cm. When the electron beam voltage is 7.5kV and the b...

Embodiment 3

[0042] Among ITO powder raw materials, In 2 o 3 : SnO 2 The weight ratio is 95%:5%, the primary particle size D50 of the powder is 45nm, and the specific surface area is 15.0m 2 / g. The ITO powder was placed in a high-temperature sintering furnace, and sintered in an oxygen atmosphere at normal pressure at a temperature of 1500° C. for 6 hours. The sintered ITO powder was mixed with a total of 2wt% of PVA and Tween-80, and dried at 80 °C. Put the fat-mixed ITO powder into a stainless steel mold, and hold the pressure at 40MPa for 3 minutes to form. Put the ITO biscuit into a high-temperature furnace, degrease at 600°C, and keep it warm for 10 hours. The degreased ITO biscuit was put into a high-temperature furnace, and sintered in an oxygen atmosphere at normal pressure at a temperature of 1500° C. for 8 hours. The density of the ITO evaporation target is 62.5%, and the resistivity is 7.2×10 -3 Ω·cm. When the electron beam voltage is 7.5kV and the beam current is 15mA,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com